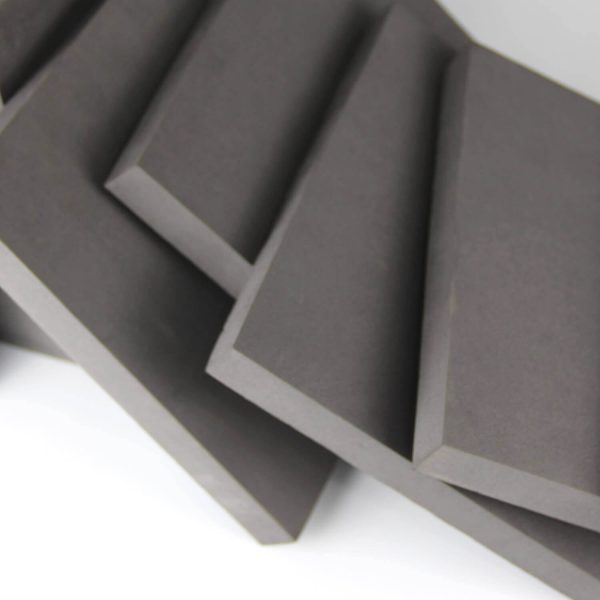

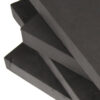

Introducing our eco-friendly, high-quality custom 8mm EVA foam sheet! Crafted with sustainability in mind, our EVA foam boasts premium durability and versatility while maintaining a commitment to environmental responsibility. Whether for DIY projects, packaging, or industrial applications, our customizable 8mm sheet offers unparalleled shape retention and reliability. Join us in prioritizing both performance and planet with our innovative EVA foam solution.

Eco-friendly High-Quality Custom 8 mm EVA Foam Sheet — Data Sheet

Specifications

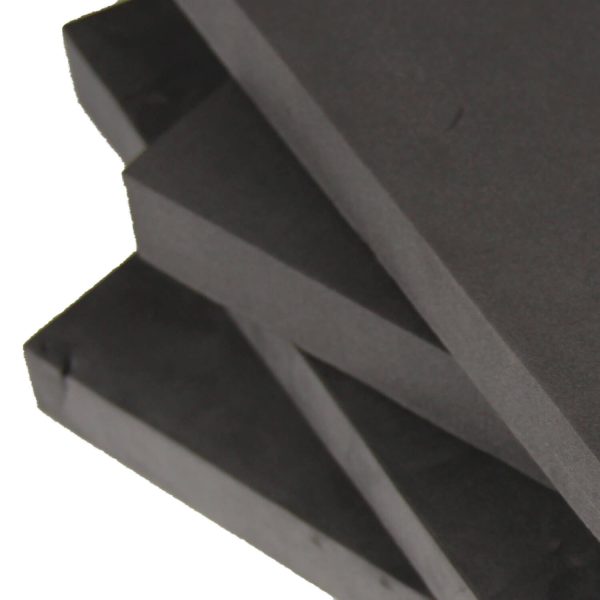

• Material: EVA (Ethylene-Vinyl Acetate), closed-cell

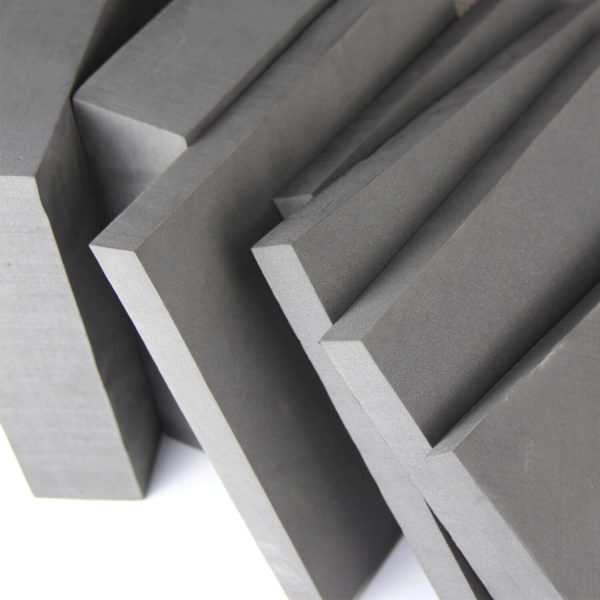

• Standard thickness: 8 mm (other thicknesses available on request)

• Density: Customizable to your application

• Hardness: 15–70 Shore C (tunable)

• Color: Any solid color with Pantone® matching available

• Origin: China

• Typical uses: Packing/protective inserts, footwear soles, baby toys, construction gaskets/insulation, decoupage, models, crafts

Performance Highlights

• Sustainable profile: Produced with recycled content and a low-carbon manufacturing process to reduce environmental impact.

• Cushioning & shock absorption: Closed-cell micro-structure provides reliable impact protection for packaging and wearable products.

• Thermal & acoustic insulation: Helps control heat transfer and dampen vibration/noise in construction and DIY applications.

• Lightweight & durable: High strength-to-weight ratio resists compression set and everyday wear.

• Safe & non-toxic: Free from harmful additives; suitable for items used around children when processed appropriately.

• Water & moisture resistant: Closed cells resist water uptake for long-lasting performance.

• Consistent finish: Smooth, uniform surface suitable for printing, laminating, and further converting.

Workability

• Easy to cut (knife, die-cut, water-jet; laser with proper ventilation)

• Heat-formable for curves and dimensional detailing

• Bonds well with contact cement, hot-melt, CA (super glue), and PSA backings

• Accepts skiving, laminating (fabric/film), embossing/texturing, and CNC profiling

Common Applications

• Packaging: Precision protective inserts, case liners, drawer organizers

• Footwear: Insoles, midsoles, light outsoles, comfort pads

• Toys & crafts: Baby toys, cosplay props, school projects, hobby models

• Construction: Gap filling, gasketing, vibration pads, thermal/acoustic layers

• Décor & DIY: Decoupage bases, signage, pattern making

Customization Options

• Thickness: 8 mm standard; full range available to spec

• Density & hardness: Tailored resilience and feel (15–70 Shore C)

• Colors & finishes: Pantone-matched solids; textured or embossed surfaces

• Converting: Die-cut blanks, kiss-cut sheets, rolls; PSA (peel-and-stick) liners; multi-layer laminations

Quality & Compliance

• Tight tolerance control on thickness and hardness

• In-process inspection for surface finish and cell integrity

• Batch traceability and supporting documentation available upon request

Logistics

• Lead time: ~25 days for standard sheets/rolls; add 1–2 weeks for value-added processes (PSA, heat lamination, looping)

• Packaging: Flat sheets or rolls, export-ready cartons/pallets

How to Specify

Please share the following to receive a quote and DFM recommendations:

Thickness (8 mm default) and size (sheet or roll dimensions)

Target density and Shore C hardness range

Color (Pantone code if applicable) and any surface texture/lamination

Converting needs (die-cut, PSA backing, kits)

End-use environment (temperature, load, exposure) to optimize material recipe