Introducing our EVA car floor mat material, EVA car floor mats are superior resistance to moisture, stains, and debris. Unlike traditional fabric or rubber mats, EVA mats are designed to be waterproof and easy to clean, making them an ideal choice for anyone who frequently transports muddy boots, wet umbrellas, or other potentially messy items in their vehicle. With a simple wipe-down using a damp cloth, you can keep your EVA mats looking like new, day after day.

Wholesale Diamond EVA Car Floor Mat Material — Data

Specifications

Material: EVA (Ethylene-Vinyl Acetate), closed-cell

Grades: A+, A, B, C

Density: 170 kg/m³ standard (customizable)

Hardness: 45–60 Shore C

Roll width: 1.5 m

Thickness: 10 mm (≈0.39 in)

Colors: Black, Grey, Aqua Blue, White; Pantone match available

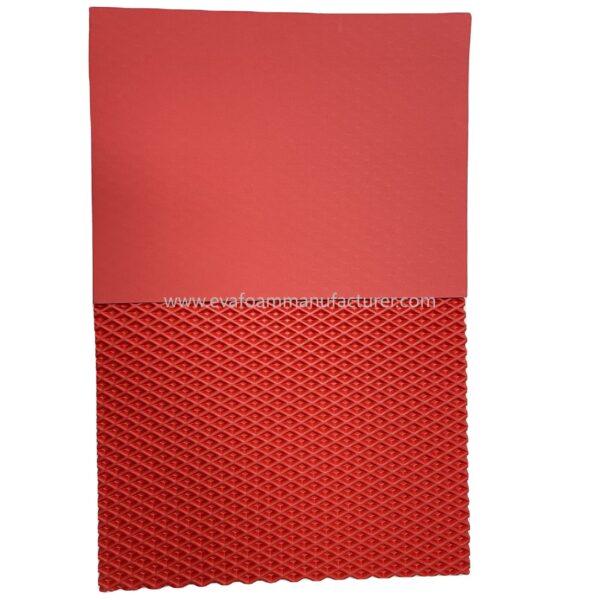

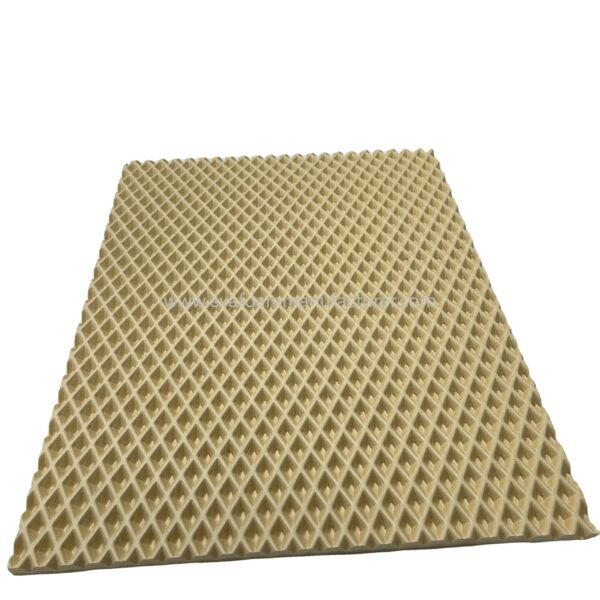

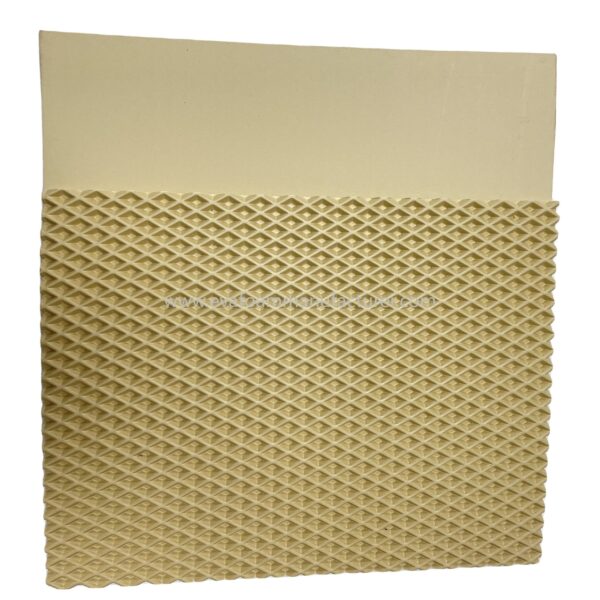

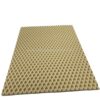

Surface: Diamond anti-slip texture

Samples: Available

Origin: China

Overview

Durable, lightweight EVA with a diamond tread for high grip and easy cleaning. Closed-cell structure resists water and dirt ingress while delivering cushioning, noise damping, and long service life—ideal for OEM and aftermarket car floor mats.

Key benefits

Traction & safety: Diamond texture improves wet and dry grip.

Easy to clean: Closed cells prevent soak-through; shake, rinse, or wipe.

Comfort & quiet: Cushions footsteps and reduces cabin vibration.

Cut-to-fit: Works for universal or vehicle-specific kits.

Stable performance: Consistent hardness and density across rolls.

Typical applications

Driver/passenger floor mats

Rear row and third-row mats

Trunk/cargo liners and load-bay pads

Utility/garage and workshop floor runners for automotive use

Customization & processing (on request)

Pre-cut vehicle kits from CAD

PSA backing, fabric/mesh lamination

Edge beveling, heel pads, logo deboss/laser mark

Perforation/drain channels, color matching, texture variants

FAQ — Diamond EVA Car Floor Mat Material

Q: What’s the lead time?

A: Standard rolls/sheets typically ship in about 25 days. Add 1–2 weeks for value-added steps like PSA, lamination, or looping.

Q: Can I get samples?

A: Yes—sample sheets are available in multiple colors and textures.

Q: Can you adjust softness or color?

A: Yes—we can tune hardness within 45–60 Shore C and match Pantone or a physical sample.

Q: Is EVA recyclable?

A: EVA can be recycled where facilities exist. We also recycle production offcuts to reduce waste.

Q: Can you make to my CAD file?

A: Yes—send your CAD/prototype. After minor DFM tweaks if needed, we can begin sample production promptly.