Orthopedic Cork Insoles: Essential Support for the Healthcare Industry

Enhance the comfort and well-being of healthcare professionals with our premium Orthopedic Cork Insoles. Designed specifically for the demanding environments of the healthcare industry, these insoles provide superior support, cushioning, and durability.

Premium cork + EVA orthopedic insoles engineered for long shifts and high-mileage wear. Designed for healthcare, retail/hospitality, industrial, and everyday comfort programs.

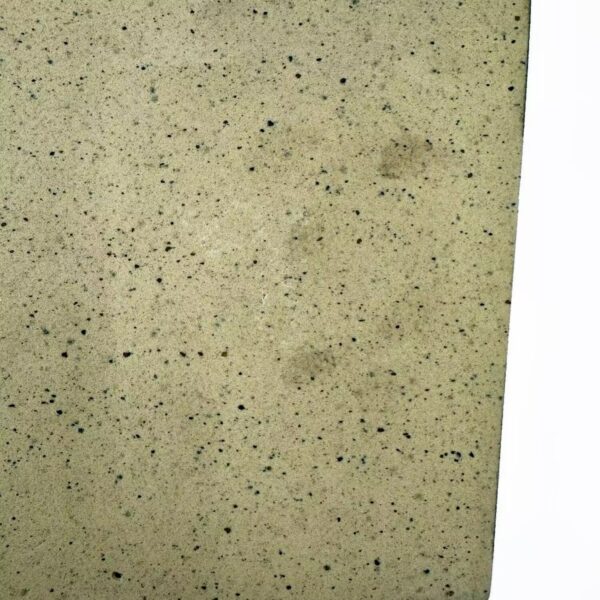

Material: Cork / EVA composite (cork top layer, EVA support core)

Applications: Orthotics, comfort insoles, medical postings, heel lifts

Density: Customizable (EVA & cork grades available)

Hardness: 25–80° Shore C (tuned by zone or layer)

Thickness: 1–57 mm single- or multi-layer; custom builds welcome

Colors: Natural cork; EVA in any solid or Pantone-matched color

Origin: CN

All-day comfort: EVA core cushions impact; cork adds gentle rebound and pressure distribution.

Stable support: Holds shape with low compression set—ideal for arch fills and postings.

Dry & fresh feel: Cork manages moisture naturally and is odor-resistant.

Trim-to-fit friendly: Cuts cleanly; available with printed size grid.

Lightweight & quiet: Reduces shoe weight and squeak versus rigid plastics.

Sustainability: Cork is harvested from renewable bark; in-plant EVA offcuts can be recycled.

Bi-layer: Natural cork topcover + EVA base (single-duro)

Tri-layer: Cork topcover + comfort foam (optional) + firm EVA posting layer

Zoned durometer: Soft forefoot / firm medial arch & heel posting

Topcovers: Microfiber, mesh, antimicrobial* textiles, or perforated cork (*antimicrobial textiles available on request)

Backings: Raw, fabric scrim, or PSA (pressure-sensitive adhesive) peel-and-stick

Formats: Full-length, ¾ length, heel cup, wedges; sheets, billets for CNC, or finished die-cuts

Clinical/orthotic labs: 3–6 mm cork + 3–10 mm EVA, 50–65° Shore C posting

Healthcare & shift work: 4–8 mm total, 35–50° Shore C comfort focus

Safety/industrial: 6–10 mm total, 55–70° Shore C stability + abrasion layer

CNC milling & grinding: Clean chip, low dust; holds detail for arch and heel cups.

Heat formable: Brief, moderate heat for gentle shaping; allow to cool on last.

Bonding: PU/contact cements or heat-activated films; light scuff + alcohol wipe recommended.

Testing (on request): Hardness ASTM D2240 (Shore C), compression set ISO 815, abrasion ISO 4649/DIN 53516.

Compliance: Latex-free builds available; REACH/RoHS-friendly options.

Private label: Printed logos on cork or textile; branded boxes or bulk poly.

Kitting: Left/right matched pairs, size-run assortments, or bulk sheet supply.

Standard lead time: ~25 days for regular builds.

Add 1–2 weeks for PSA backings, heat lamination, or complex multi-layer stacks.

Samples: Texture/durometer swatch kits and pre-size runs available.

Can you match our clinic’s firmness and color?

Yes—target Shore C and Pantone or a physical chip. Zonal durometer available.

Do you offer finished, ready-to-sell insoles?

Absolutely—full-length and ¾, trimmed to EU/US/UK size runs with retail packaging.

Can these be recycled?

Cork is renewable; EVA offcuts are recycled in-plant. Post-use options depend on local facilities.

What files do you need for custom milling?

DXF/STL/CAD with thickness map and material stack. If only minor edits are needed, sample production typically starts within two weeks.