Closed Cell Foam for Boats: Premium Marine Cushioning and Protection

Elevate your boating experience with our high-quality closed cell foam for boats. Engineered specifically for marine environments, this advanced foam offers superior cushioning, durability, and protection, making it an essential addition to any boat.

Superior Durability

Our closed cell foam for boats is designed to endure the harshest marine conditions. Its closed cell structure is highly resistant to water, UV rays, and general wear and tear, ensuring long-lasting performance and maintaining its integrity over time.

Enhanced Comfort and Safety

Experience exceptional comfort with our closed cell foam, which provides a cushioned surface that reduces fatigue and enhances safety on board. Its non-slip properties help prevent accidents, making it ideal for use in seating, decking, and other high-traffic areas of your boat.

Closed-Cell Foam for Boats — Product Data

Marine-grade, closed-cell EVA sheet engineered for boat decks and pads. Delivers non-slip comfort, shock absorption, and long-term durability in sun, salt, and spray. Supplied as full sheets or CNC-cut kits.

Material: EVA (closed-cell foam)

Density: 185 kg/m³ standard (other densities available)

Sheet size: 2.4 m × 1.2 m × 6 mm standard

Thickness: Per request (common 3–10 mm; multi-layer builds available)

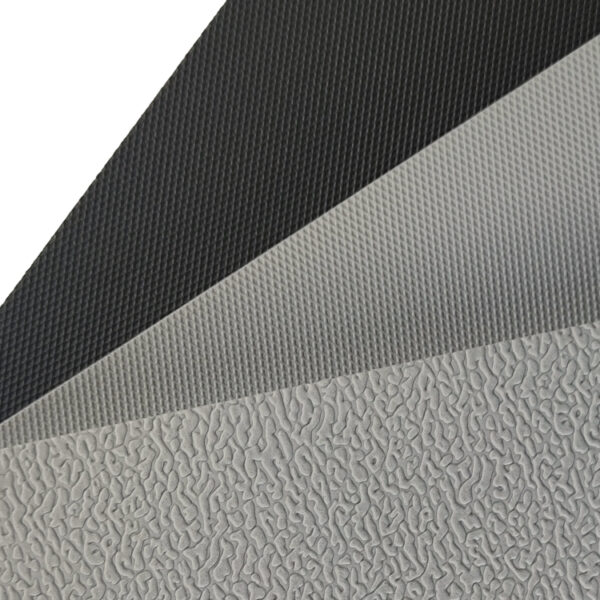

Colors: Solid or two-tone; Pantone-matched on request

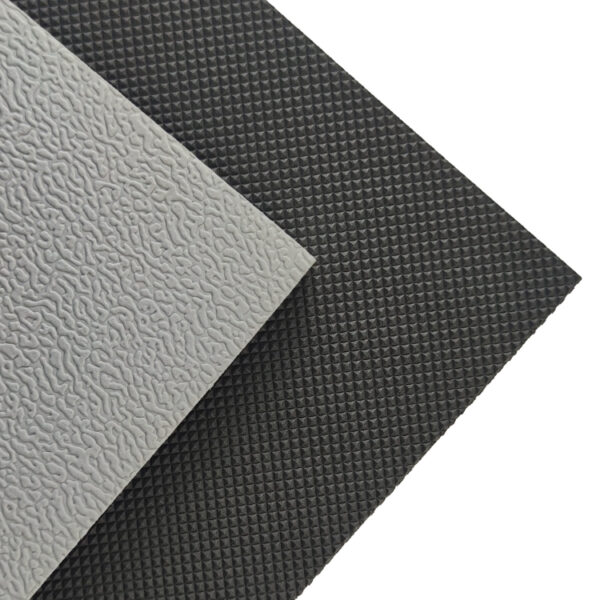

Surface options: Brushed, diamond/pebble, or teak-style grooves

Adhesive: Optional marine-grade PSA (e.g., 3M™ backing)

Resistance: UV, water, and mildew resistant; low water uptake

Origin: CN

Use class: Marine flooring / “rubber” decking alternative for boats

Wet-grip safety: Textured, non-slip surface for confident footing.

Comfort & protection: Cushions impact, dampens vibration, and insulates from heat/cold.

Built for marine: Closed-cell structure resists soak, staining, and delamination.

Lightweight & quiet: Reduces deck weight and hull noise.

Easy to work with: Cuts cleanly; kits can be supplied from CAD for drop-in fit.

Boat decks & cockpits • Swim platforms • Helm/stand pads • Steps & gunwales • Hatches & lockers • Cooler lids • Kayaks/SUPs • RV and poolside crossover areas

Density/firmness tuning

Thickness and bevel/edge profiles

Groove patterns, logos, registration marks, and laser/Router details

Single or double-layer color builds

Sheet, roll, or pre-templated kit packs from CAD/DXF

Backing choices: loose-lay, perimeter-bond, or full-sheet PSA

Prep: Clean, dry, and de-wax surface; repair chips; confirm drainage/slope.

Layout: Dry-fit sheets; mark centerlines; allow material to relax flat.

Bond: Peel small sections of liner; align and squeegee from center outward to avoid air.

Roll: Firmly roll all areas (especially edges/seams).

Cure: Keep dry and unladen per adhesive guidance before heavy use.

Tip: Radius sharp corners and seal exposed edges where needed.

Rinse after use; scrub with mild soap and soft brush. Promptly lift fish blood/sunscreen/wine with gentle cleaners. Avoid harsh solvents/bleach. Periodically check edges and high-traffic zones.

Lead time: Standard sheets ship in ~25 days; add 1–2 weeks for PSA backing, special lamination, or kit sets.

Samples: Yes—color/texture swatches and small panels available.

Soft/firm options: We tune compound/expansion to your preferred feel.

Recyclability: EVA closed-cell foam can be recycled where facilities exist; production offcuts are recycled in-plant.

Build from CAD: Yes—send CAD/DXF or paper templates for CNC-cut kits; sample runs typically start within two weeks.

Boat make/model and total coverage (m²)

Area map (deck, helm pad, swim platform, steps, hatches)

Thickness & density preference

Pattern/texture and color (single or two-tone)

Edge bevels, logos, and cutouts

Backing/bonding method (PSA/perimeter/full-bond)

Deliverables (full sheets vs. kit) and timeline

Share the checklist and any drawings/templates to receive a tailored specification, sample set, and quotation.