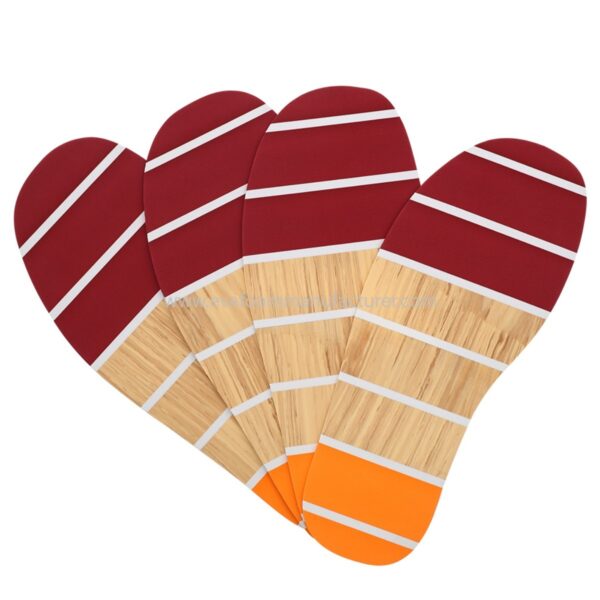

Introducing our 2025 trendy cork EVA orthotic sole: Our orthotic soles are made from a unique blend of cork and EVA materials, combining the best properties of both. The cork provides a natural, sustainable, and shock-absorbing base, while the EVA material adds flexibility and additional cushioning. This combination ensures that our soles not only feel great but also contribute to a more eco-friendly world.

2025 Trendy Cork EVA Orthotic Sole — Product Data

PRODUCT OVERVIEW

Composite cork + EVA orthotic sole material engineered for supportive, all-day comfort. The cork layer conforms to foot shape for natural arch support, while the closed-cell EVA provides lightweight, responsive cushioning. Ideal for insoles, midsoles, and footbeds across casual, athletic, and occupational footwear.

TECHNICAL SPECIFICATIONS

Material: Cork/EVA composite (EVA = closed-cell foam)

Applications: Footwear (insoles, midsoles, footbeds); sheet grade also suitable for luggage inserts, swim boards, floor mats, and packaging spacers

Density: Customizable to project targets

Hardness: 25–80 (Shore scale per spec)

Patterns: Multiple traction/texture options available

Color: Customized or Pantone-matched

Thickness: As per customer request

Origin: CN

Feature: “Sole rubber sheet” format for die-cutting/lamination; pre-cut kits on request

KEY BENEFITS

Comfort & Support: Cork micro-conforms for personalized arch support; EVA layer disperses pressure and absorbs shock.

Lightweight Performance: Closed-cell structure keeps weight low without sacrificing resilience.

Stable & Durable: High rebound with low compression set for long wear life.

Trim/Laminate Friendly: Cuts cleanly, bonds well in multi-layer footbeds; wide hardness window fits neutral, motion-control, or cushioned builds.

Style Ready: Broad color palette and surface patterns for branded looks.

FORMATS & CUSTOMIZATION

Sheet sizes for die-cutting; pre-cut insole/midsole kits per size run

Hardness/density tuning (25–80 Shore)

Thickness build-ups (single or multi-layer)

Surface textures (smooth, brushed, micro-rib, etc.)

Logo embossing, color accents, CNC profiling from CAD/DXF

INTEGRATION GUIDELINES

Cutting: Die-cut or CNC for accuracy; deburr edges for in-shoe comfort.

Bonding: Use compatible contact or hot-melt adhesives; follow press/flash times recommended by the adhesive supplier.

Assembly: Layer with foams, fabrics, or top covers as needed; ensure full-surface contact to avoid lift.

Fit: Trim-to-fit options available for aftermarket insoles.

CARE & MAINTENANCE

Wipe clean with mild soap; air dry away from direct heat/UV.

Inspect high-pressure zones periodically for wear; replace as needed.

FREQUENTLY ASKED QUESTIONS

Lead Time: Standard sheets/kits typically ship in ~25 days; add 1–2 weeks for PSA backing, heat lamination, custom textures, or kit-packing.

Samples: Yes—sample sets available in multiple densities, hardnesses, and finishes.

Soft/Firm Options: Formulation can be tuned across the 25–80 Shore range to your preferred feel.

Recyclability: EVA closed-cell foam is recyclable where facilities exist; production offcuts are recycled in-plant.

Build from CAD: Yes—provide CAD/DXF and size run; with minor revisions, sample production can usually begin within two weeks.

ORDERING CHECKLIST

Shoe category (casual, athletic, work, orthotic) and total pairs (size run)

Target feel/performance (cushion, stability, motion control)

Hardness/density and thickness stack-up

Surface pattern, color, and any branding/emboss needs

Format (sheets vs. pre-cut kits) and bonding/top-cover requirements

Packaging, labeling, and delivery timeline

Share the checklist to receive a tailored specification and quotation.