Applications:

Our Closed Cell EVA Foam Sheets find versatile applications within the packaging milling industry:

Industrial Packaging: Ideal for creating custom inserts and liners that protect sensitive components and electronics from static electricity and mechanical shock.

Food and Beverage: Used in food packaging to cushion perishable items and prevent breakage during transportation.

Pharmaceuticals: Ensures the safe transit of medical supplies and pharmaceutical products, maintaining their sterility and integrity.

Consumer Electronics: Provides effective insulation and protection for electronic gadgets and appliances, safeguarding against impact and moisture damage.

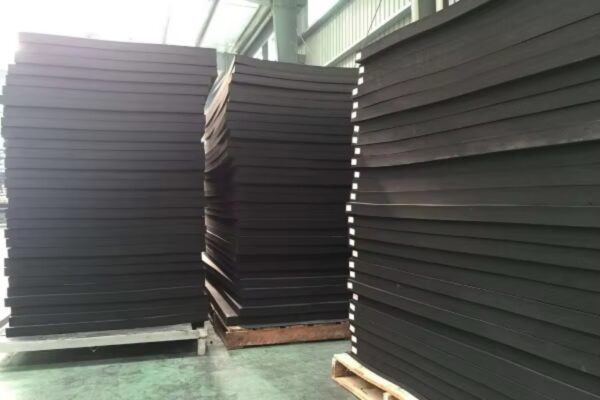

China Wholesale EVA Foam Sheet Manufacturer — Product Profile

Product Data

Material: EVA (closed-cell foam)

Applications: Packing, soles, baby toys, construction, decoupage, models, and more

Most popular use: Hotel slipper components

Hardness: 15–85 (customizable)

Available colors: Any color, including Pantone matching

Thickness: As requested (sheet or roll)

Origin: China (CN)

Feature: Suitable for insulation, cushioning, and shock absorption

Introducing Our China Wholesale EVA Foam Sheet Manufacturer

We supply consistent, factory-direct EVA foam sheets and rolls engineered for durability, clean processing, and reliable performance. Tight tolerances on thickness and hardness, broad color options, and fast tooling turnaround make us a dependable partner for OEMs, brands, and makers.

Key Advantages

Quality assurance: Batch consistency with rigorous incoming material and in-process checks

Cost efficiency: Direct factory pricing and bulk discounts

Customization: Thickness, hardness, color, surface texture, and PSA (self-adhesive) options

Reliable supply chain: Stable lead times and export logistics to global destinations

Easy processing: Cuts cleanly (blade, die, waterjet/CNC; laser where permitted), heat-forms, sands, and bonds well

Typical Applications

Packaging: Custom inserts, edge/corner protection, vibration damping

Construction/Insulation: Thermal and acoustic insulation layers, expansion joint fillers, underlayment

Sports & Recreation: Exercise/yoga mats, playground tiles, protective padding

Arts & Crafts: Cosplay, props, models, signage, displays

Automotive: Interior padding, carpet underlay, anti-rattle strips, soundproof layers

Footwear: Outsoles, midsoles, insoles, linings

Health Care: Orthopedic insoles, arch supports, custom braces

Marine: Decking inlays, fenders, cooler-box mats

Specification Options

Thickness & size: From thin gaskets to thick pads; master sheets, custom cut sheets, or rolls

Hardness (Shore C/As requested): 15–85 to match feel and load requirements

Colors & finishes: Black, white, and full Pantone match; smooth or textured/embossed

Laminations: Fabric/film skins, foil, or double-sided composites

Adhesive backing: Industrial PSA (peel-and-stick), slit to width or kiss-cut parts

Processing & Converting (on request)

Die-cutting, kiss-cutting, CNC routing, waterjet

Heat lamination, beveling, skiving, profiling

Kitting and custom packaging for assembly lines

Sustainability

EVA off-cut recycling in-house where feasible

Option to consolidate shipments and optimize pack-outs to reduce waste

Frequently Asked Questions

What is the typical lead time for custom EVA foam?

Standard rolls and sheets: about 25 days for shipping.

With PSA, heat lamination, embossing, or looping: add approximately 1–2 weeks.

Can I receive samples to test quality?

Yes. Sample packs with multiple thicknesses, textures, and colors are available.

Can the foam be made softer or harder?

Yes. We tune compounding and expansion to reach your target firmness. We can also color-match to your Pantone or physical sample.

Is EVA foam recyclable?

EVA closed-cell foam can be recycled where local facilities exist. We recycle shop off-cuts to minimize waste.

Can you manufacture from my CAD file?

Yes. If only minor revisions are needed, we can typically produce a sample within about two weeks.

Next Steps

Share your target thickness, hardness, color, sheet/roll size, and any PSA or lamination needs. Request a sample or a fast quote, and we’ll recommend the most cost-effective specification for your application.