In the milling industry, precision and protection are vital for packaging products. Closed cell PE foam stands out as an ideal choice, offering durability, flexibility, and exceptional protective properties tailored to meet industry needs.

Superior Protection

Closed cell PE foam provides robust protection for milling equipment and products. Its dense, non-permeable barrier safeguards against impacts, vibrations, moisture, and dust, ensuring that precision tools and components remain undamaged during transit and storage.

Exceptional Cushioning

The foam offers excellent cushioning and shock absorption, crucial for high-value and sensitive items like milling cutters and precision tools. It effectively absorbs and dissipates energy from impacts, maintaining its shape and providing reliable, long-lasting protection.

Versatile and Customizable

Closed cell PE foam can be customized to meet specific packaging requirements, whether for inserts, dividers, or custom-molded shapes. This versatility ensures optimal protection for items of any size or shape, enhancing packaging efficiency and reducing waste.

Lightweight and Efficient

Despite its robust qualities, the foam is lightweight, making it easy to handle, transport, and integrate into automated packaging systems. This reduces shipping costs and streamlines the packaging process, boosting productivity.

Moisture and Chemical Resistance

Closed cell PE foam is resistant to moisture and many chemicals, providing additional protection in milling environments. This prevents corrosion and degradation, extending the shelf life of both the foam and the products it protects.

Environmentally Friendly

Made from recyclable and non-toxic materials, closed cell PE foam is an environmentally friendly option. Its long lifespan and reusability contribute to sustainability by reducing waste and supporting eco-friendly practices.

Conclusion

Closed cell PE foam revolutionizes packaging in the milling industry with its superior protection, versatility, and efficiency. Its cushioning, lightweight nature, moisture and chemical resistance, and environmental benefits make it the ultimate packaging solution. Embrace the advantages of closed cell PE foam to ensure your milling products are protected with the best in the industry.

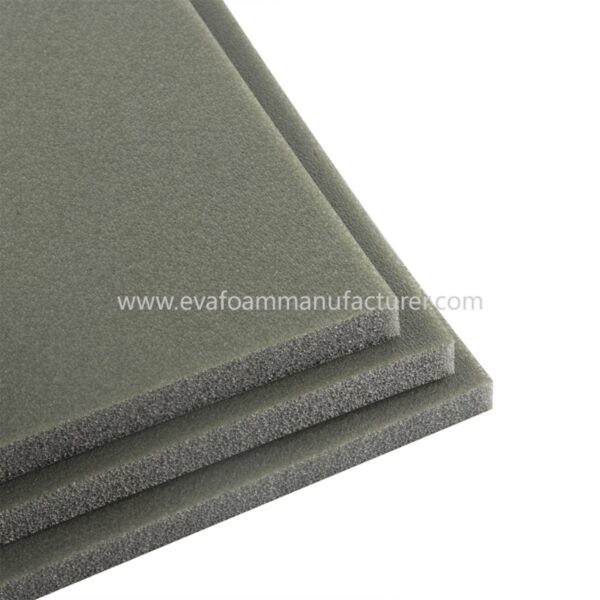

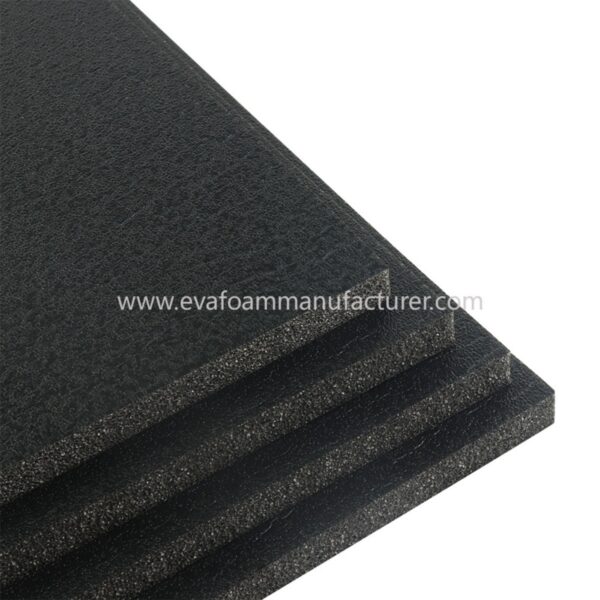

Bulk Buy Closed-Cell PE Foam — Data

Specifications

Material: PE foam (closed-cell)

Features: Closed-cell, waterproof, non-toxic

Density: Customizable (per customer request)

Size: 1.5 × 52.95 m per block

Hardness: 15–40° (customizable)

Thickness: 1–105 mm

Samples: Available

Origin: China

Typical applications: Industrial gasketing, flotation, cushioning

Overview — Factory Die-Cut Closed-Cell PE Foam for the Milling Industry

Engineered for demanding packaging workflows in milling operations, our closed-cell PE foam protects precision tools and components in transit and storage.

Key benefits

Impact & vibration protection: Dense, resilient cells cushion cutters, spindles, fixtures, and calibrated parts.

Barrier performance: Closed-cell structure resists moisture, oils, dust, and debris to keep items pristine.

Lightweight efficiency: Low mass reduces shipping costs and integrates smoothly with automated packing.

Chemical resistance: Withstands common shop chemicals to extend the life of both foam and packaged goods.

Consistent quality: Tight control over density/hardness for repeatable die-cut results and snug fitment.

Typical use cases

Tooling trays and drawer inserts for end mills, drills, and holders

Dunnage, dividers, and cavity trays for workholding and spare parts

Returnable rack padding and edge/protective guards

Export crating liners and shock-isolation pads

Customization & processing (on request)

Die-cutting from CAD, kiss-cut sets, CNC routing, waterjet

PSA backing, lamination (films/fabrics), color-coding

Multilayer builds, scoring/perforation, emboss/deboss logos

Density and hardness tuning to your spec

Closed-Cell PE Foam — Cross-Industry Applications

Arts & Crafts: Costume and cosplay builds, general handicraft, scrapbook accents

Automotive: Sound proofing, car mats, interior and carpet padding, shock absorption

Footwear: Outsoles, insoles, linings

Health Care: Orthopedic insoles, arch supports, custom supports

Marine: Decking, pads/mats, fenders, cooler-box liners

Sports & Leisure: 1 m × 1 m mats, baby play mats, yoga and kneeling mats

FAQ — Closed-Cell PE Foam

Q: What’s the lead time?

A: Standard rolls/sheets typically ship in about 25 days. Add 1–2 weeks for value-added steps such as PSA (pressure-sensitive adhesive), heat lamination, or looping.

Q: Can I get samples?

A: Yes. Sample sheets/roll cuts are available in multiple colors and textures.

Q: Can you adjust softness or color?

A: Yes. We can tune softness/firmness by formulation and match colors to your Pantone or physical sample.

Q: Is it recyclable?

A: Closed-cell PE foam can be recycled where facilities exist. We also recycle in-house offcuts to reduce waste.

Q: Can you produce from my CAD file?

A: Yes. If only minor DFM tweaks are needed, we can initiate sample production quickly after file review.