Premium EVA Foam Boat Decking Sheet: Enhance Your Yacht Experience

Upgrade your yacht with our high-quality EVA foam boat decking sheet, meticulously designed to deliver superior comfort, durability, and safety. Ideal for marine environments, this decking sheet enhances both the functionality and aesthetics of your yacht.

Factory Direct Wholesale EVA Foam Boat Decking Sheet — Product Data

Product Overview

Marine-grade, closed-cell EVA decking supplied factory-direct for boats, RVs, poolsides, and outdoor walkways. Delivers soft underfoot comfort, strong wet-grip traction, and dependable UV/salt resistance with fast turnaround and online technical support.

Technical Specifications

Material: EVA (closed-cell)

Density: 120 kg/m³

Standard Sheet Sizes: 2.4 × 1.2 m × 6 mm; 2.1 × 1.1 m × 6 mm (custom sizes available)

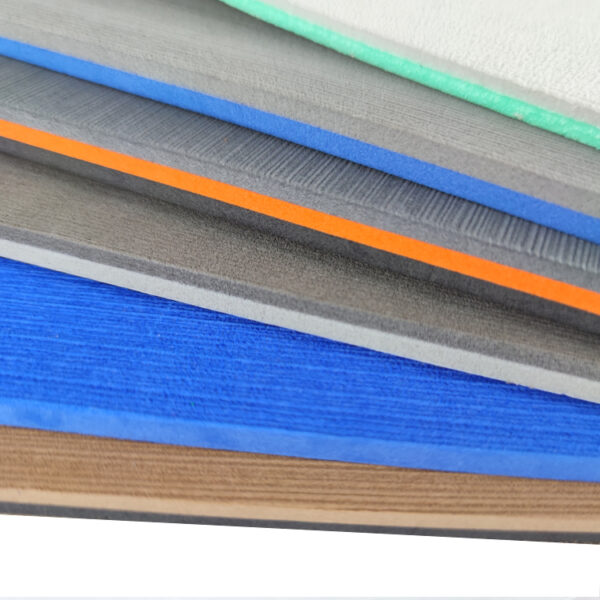

Nominal Thickness: 6 mm (other thicknesses on request)

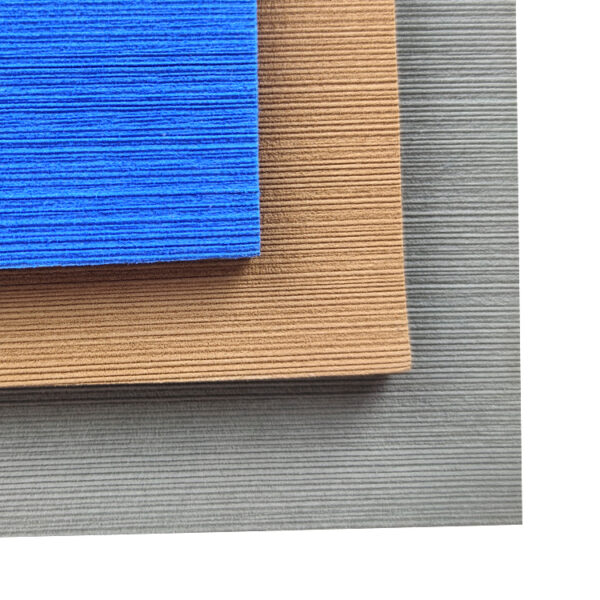

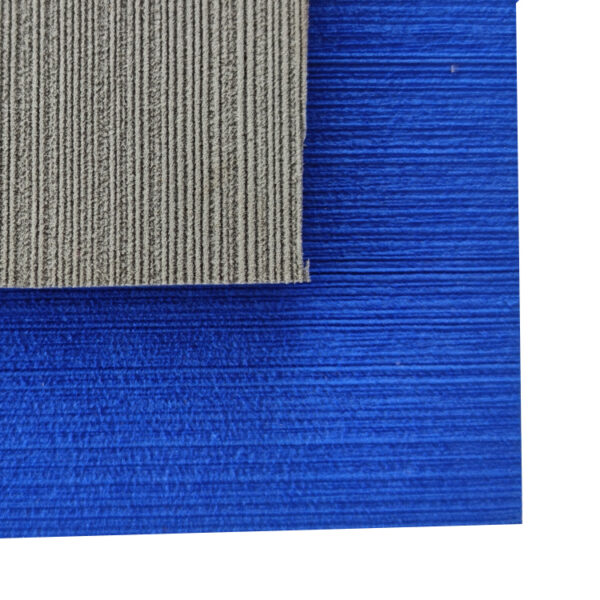

Colors/Patterns: Any solid or Pantone-matched color; pattern options on request

Anti-UV: Yes

Compliance: Formamide testing report available

Origin: CN

Applications: Boat/yacht flooring, RV flooring, swimming-pool surrounds, garden/outdoor flooring

After-Sales: Online technical support

Key Benefits

Non-slip safety in wet conditions

Cushioning comfort; reduces vibration and fatigue

Weatherable: UV, salt, and mildew resistant

Lightweight, quiet, and easy to clean

Trims cleanly for hatches, edges, and custom inlays

Customization & Services

Custom colors, logos, patterns, and routing

CNC pre-cut kits from your CAD or paper templates

Optional marine-grade PSA (adhesive) backing for peel-and-stick install

Edge beveling, teak-style lines, and camo/dual-color options

Installation Summary (PSA-Backed)

Surface prep: Clean, dry, and de-grease; fair uneven areas.

Dry-fit: Position and mark alignment.

Apply: Peel liner gradually; press from center outward.

Roll: Use a laminate roller for full bond and edge seating.

Cure: Keep dry and light-use only for 24–48 hours.

Care & Maintenance

Rinse after outings; wash with mild soap and a soft brush.

Avoid harsh solvents, wire brushes, and close-range high-pressure jets.

Treat stains promptly with marine-safe cleaners.

Frequently Asked Questions

What’s the lead time?

Standard sheets typically ship in ~25 days. Add 1–2 weeks if PSA backing, heat lamination, or custom routing is required.

Can I get samples?

Yes—sample kits are available in multiple textures, colors, and thicknesses.

Can you adjust softness/firmness or match colors?

Yes—compound hardness can be tuned, and colors can be matched to Pantone or a supplied sample.

Is it recyclable?

EVA can be recycled where facilities exist; production off-cuts are recycled in-house to reduce waste.

Can you cut from my CAD file?

Yes—if only minor revisions are needed, sample production can begin in roughly two weeks.

Next Steps

Provide target sizes, quantity, preferred color/texture, drawing or CAD/template, and whether you need PSA backing. A confirmation spec and quotation will be prepared promptly.