High quality EVA Foam Sheets Marine: Perfect for the Marine Industry

Enhance your marine vessel with our premium EVA Foam Sheets Marine, designed to deliver superior comfort, durability, and safety. Ideal for various marine applications, these foam sheets are perfect for decking, flooring, and more, ensuring your boat performs at its best.

Choose our EVA Foam Sheets Marine to elevate the comfort, safety, and aesthetics of your boat’s surfaces. Experience the benefits of superior cushioning, durability, and easy maintenance with this high-performance foam solution, specifically designed for the marine industry.

Wholesale SeaDek-Quality 60 EVA Foam Sheets — Marine

Product Overview

Durable, non-slip EVA decking sheets engineered for boats and yachts. Comfortable underfoot, UV-resistant, and built to handle salt, sun, and frequent washdowns.

Technical Data

Material: EVA

Density: 120 kg/m³

Standard sizes: 29×29 cm, 31×31 cm, 62.5×62.5 cm, 1×1 m

Thickness options: 3 mm, 5 mm, 6 mm, 8 mm

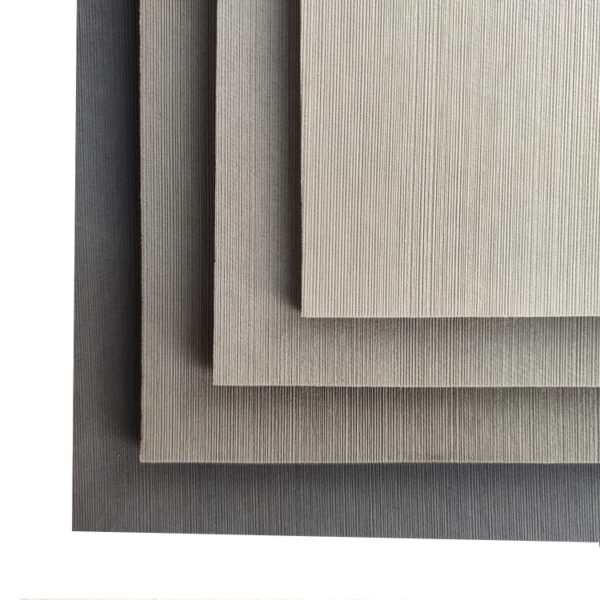

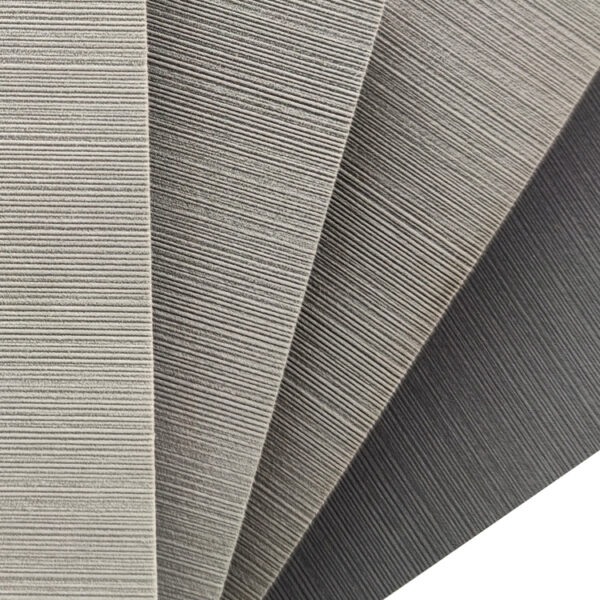

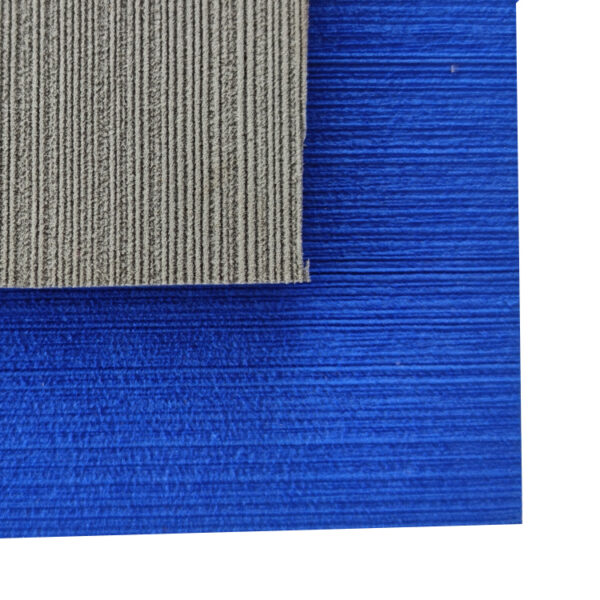

Colors: Any color; Pantone matching available

Application: Boat and yacht surfaces

Anti-UV: Yes

Formamide: Testing report available

Project support: Graphic design (templates, layouts)

Origin: CN

Key Benefits

Traction & safety: Textured, non-slip surface for wet decks, steps, and swim platforms.

Comfort: Cushions vibration and reduces fatigue during long days on the water.

Weather tough: Resists UV, saltwater, and mildew for long-lasting appearance.

Easy to work with: Cuts cleanly and conforms to curves; simple to fit and replace.

Low maintenance: Rinses clean; stains and scuffs wipe away easily.

Customizable look: Single or dual-color options, patterns, and logo inlays available.

Typical Marine Applications

Decking and cockpit floors

Helm pads and standing mats

Swim platforms and transom steps

Cabin sole runners and companionway treads

Gunwales, coolers, hatch lids, and locker liners

Trailer bunks and fender guards

Options & Services

Custom sizes and kit sets to your templates

Pattern choices (brushed, diamond, teak-style, etc.)

Edge beveling, routing, and logo inlays

Optional PSA (peel-and-stick) backing for fast installation

CAD/graphic design support for complex layouts

Installation Tips (summary)

Clean and dry substrate thoroughly (degrease).

Test-fit and mark alignment; dry-fit all pieces first.

Peel small sections of liner at a time; apply firm pressure.

Roll or press evenly; allow adhesive to cure before heavy use.

Care & Maintenance

Rinse with fresh water after use; mild soap for spills.

Avoid harsh solvents and wire brushes.

For stubborn marks, use a soft brush with diluted cleaner.

Frequently Asked Questions

What is the typical lead time?

• Standard rolls and sheets usually ship in about 25 days. Add 1–2 weeks for PSA backing, heat lamination, embossing, or other special processing.

Can I get samples?

• Yes. Sample packs are available in multiple thicknesses, textures, and colors.

Can the hardness be adjusted?

• Yes. We can tune the compound for softer or firmer feel and match colors to Pantone or a physical sample.

Is the foam recyclable?

• EVA can be recycled where facilities exist. We recycle in-process off-cuts to reduce waste.

Can you make parts from my CAD file?

• Yes. If only minor revisions are needed, we typically produce a sample in about two weeks.

Next Steps

Share your target size, thickness, color, pattern, and whether you need PSA backing. We’ll recommend a cost-effective spec, send samples, or provide a fast quote.