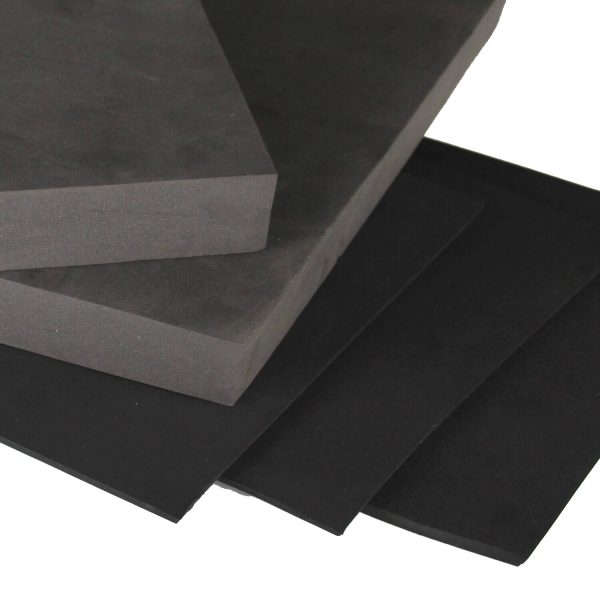

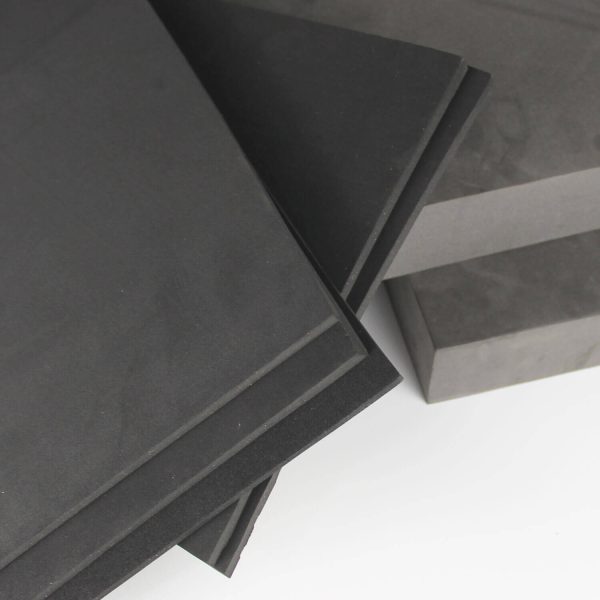

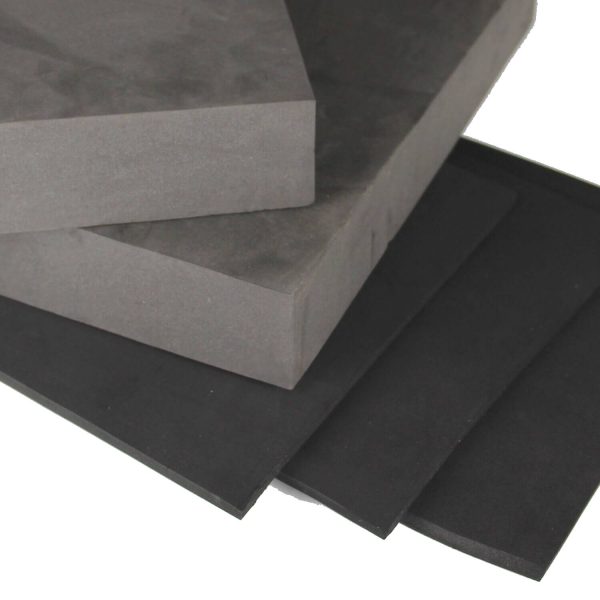

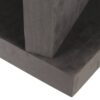

Introducing our premium 10mm EVA foam sheet product, designed to elevate your creative projects in the shoe material and shoe sole industry, packing, automotive, artcraft fields. Crafted with precision and engineered for excellence, our foam sheets are the go-to choice for professionals in these dynamic industries. 10mm EVA foam sheet is a high-density EVA foam (100kg/M3) with a closed-cell smooth surface. It is waterpoof.With its 10mm thickness, it provides the perfect balance between flexibility and strength, making it an ideal crafting material for intricate designs and everyday use.

10mm EVA Foam Sheets — Data Sheet

PRODUCT OVERVIEW

Closed-cell ethylene-vinyl acetate (EVA) foam sheets engineered for durable cushioning, clean conversion, and consistent performance. Ideal for crafts, automotive liners, footwear components, case inserts, and general packaging.

CORE SPECIFICATIONS

Material: EVA (Ethylene-Vinyl Acetate), closed-cell

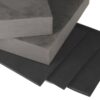

Grades: A+, A, B, C

Nominal Density: 100 kg/m³ (customizable)

Hardness: 45–50 Shore C (other durometers available)

Thickness: 10 mm (≈ 0.39 in)

Roll Width: 1.5 m

Colors: Aqua Blue, White, or Pantone color-matched

Origin: CN

Samples: Available

KEY FEATURES

Cushioning & Impact Protection: High energy absorption with resilient rebound for repeated use.

Consistency: Tight control of density, thickness, and color for reliable downstream processing.

Closed-Cell Waterproofing: Resists moisture ingress; easy to wipe clean.

Lightweight & Easy to Convert: Cuts, routes, or die-cuts cleanly; compatible with CNC and water-jet.

Customizable: Density, hardness, color, surface texture, and sheet/roll format tailored to your build.

TYPICAL APPLICATIONS

Arts & Crafts: costume/cosplay builds, prop making, scrapbooking accents.

Automotive: sound-damping pads, trunk/door liners, anti-rattle spacers, floor-mat bases.

Footwear: outsoles, midsoles, insoles, liners.

Health Care: orthotic blanks, arch supports, comfort padding.

Marine: deck padding, cooler liners, fenders.

Sports & Leisure: 1 m × 1 m sport tiles, yoga/kneeling mats, baby play mats.

Packaging: case inserts, presentation trays, shock pads.

CONVERTING & ADD-ON SERVICES

Cutting: die-cut, kiss-cut, CNC routing, water-jet.

Forming: heat forming/thermo-shaping for 3D contours.

Bonding: hot-melt, contact adhesive, cyanoacrylate; optional PSA (peel-and-stick) backing.

Lamination: fabric/film overlays, multi-layer composites, color-cap layers.

Finishing: bevels, radii, embossed textures, logo print, kitting and custom packaging.

PERFORMANCE NOTES

Shock & Vibration Damping: Suitable for repetitive impact environments.

Acoustic & Thermal Buffering: Helps reduce noise and mild temperature transmission.

Low Maintenance: Non-fibrous, non-dusting surface; easy cleaning.

HOW TO SPECIFY (FOR QUOTES)

Quantity and roll/sheet size (usable width/length, nesting needs).

Density target (default 100 kg/m³) and hardness range (default 45–50 Shore C).

Color (Pantone code if needed) and any surface texture/finish.

Converting method and dimensional tolerances.

Add-ons (PSA backing, laminations, printing, edge finish, kitting).

End-use conditions (temperature, humidity, chemical exposure) and any test requirements.

LOGISTICS

Lead Time: ~25 days for standard 10 mm rolls/sheets. Add 1–2 weeks for PSA, heat lamination, or looping/multi-step builds.

Packing: Rolls or flat sheets; export-ready cartons/pallets.

FAQ

Q: Can I get samples?

A: Yes—sample sets in multiple colors/textures are available for evaluation.

Q: Can you adjust softness/firmness?

A: Yes—density and hardness can be tuned to your cushioning or stiffness targets.

Q: Is EVA recyclable?

A: EVA closed-cell foam can be recycled; in-house off-cut recycling helps minimize waste.

Q: Can you build from my CAD file?

A: Yes—send STEP/DWG/DXF. We’ll review for manufacturability and produce samples quickly.