Applications:

Our custom black EVA foam sheets are utilized across various industries, including:

Packaging: Provides cushioning and protection for fragile items during shipping and handling, ensuring they arrive intact and undamaged.

Automotive: Used for gaskets, seals, and interior linings to reduce noise, vibration, and harshness (NVH) levels in vehicles.

Sports and Leisure: Ideal for creating comfortable and durable padding in sports equipment, footwear, and protective gear.

Construction: Acts as insulation and vibration dampening material in building and construction applications, enhancing comfort and reducing noise transmission.

Custom 1mm, 2mm, 5mm & 6mm Black EVA Foam Sheets — Product Data

Material: EVA (closed-cell foam)

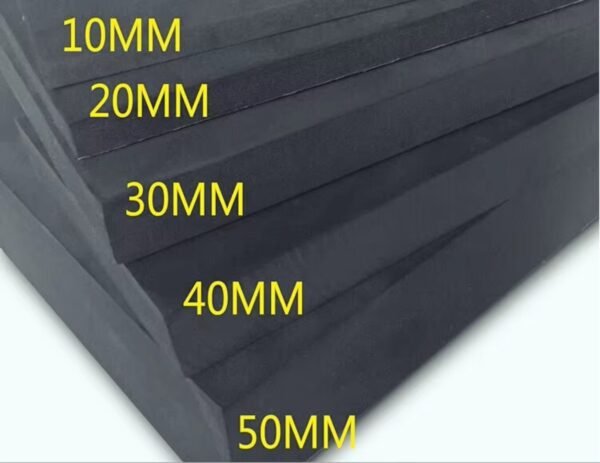

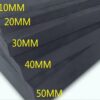

Standard thicknesses: 1 mm, 2 mm, 5 mm, 6 mm (custom thicknesses available)

Hardness: 15–85 (as specified)

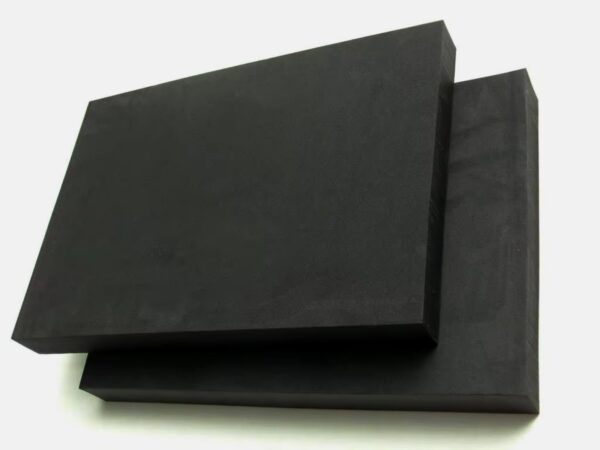

Color: Black (custom/Pantone color matching available)

Finish options: Smooth or textured; optional self-adhesive (PSA) backing

Origin: CN

Feature: Engineered for packaging, footwear, crafts, construction, models, and more

Why Choose Our Black EVA Foam Sheets

Made to your spec: Tight control of thickness, hardness, and finish for repeatable results.

Clean, professional look: Deep black color hides scuffs and makes tool inserts and gaskets look premium.

Easy to process: Cuts cleanly (blade, die, laser*), heat-forms, sands, and bonds with common adhesives.

Durable & light: Closed-cell structure resists water, oils, and impact while keeping weight low.

*Laser cutting depends on local regulations/equipment; test first.

Quick Thickness Guide

1 mm: Labels, shims, light gaskets, dust seals, craft overlays, anti-rattle pads.

2 mm: Case liners, drawer liners, light cushioning, acoustic damping layers.

5 mm: Protective packaging inserts, cosplay parts, small tool inserts, padding.

6 mm: Toolbox organizers, camera/drone case foam, ergonomic grips, cosplay armor bases.

Applications (examples)

Arts & Crafts

Costume & cosplay parts

Handicraft components

Scrapbook/DIY decorations

Automotive

Sound proofing layers

Car mats & interior padding

Carpet underlay, shock absorption

Footwear

Outsoles, insoles, linings

Health Care

Orthopedic insoles

Arch supports

Custom supports

Marine

Boat decking inlays

Fenders & bumpers

Cooler-box mats

Sports & Leisure

1 m × 1 m sports mats

Baby play mats, yoga & kneeling mats

Customization Options

Thickness & sheet/roll size cut to order

Hardness tuning within 15–85 range

Surface texture, embossing, or lamination (fabric/film)

PSA backing (peel-and-stick)

Die-cutting, kiss-cutting, CNC routing, waterjet (as applicable)

Frequently Asked Questions

What is the lead time for custom EVA foam?

Standard rolls/sheets typically ship in ~25 days. Adding PSA, heat lamination, or looping can extend lead time by 1–2 weeks.

Can I receive samples to test quality?

Yes—sample packs of sheets/rolls in multiple textures and colors are available on request.

Can you make the foam softer or harder?

Absolutely. We adjust compounding and expansion to hit your target feel. We also color-match to your sample or Pantone.

Is EVA foam recyclable?

EVA closed-cell foam can be recycled where facilities exist. We also recycle in-house offcuts to reduce waste.

Can you build from my CAD file?

Yes. If only minor tweaks are needed, we can typically produce a sample within about two weeks.

Call to Action

Want to test fit and finish? Request a sample and share your target thickness/hardness, size, and any PSA or lamination needs.