Introducing our premium Ethylene-Vinyl Acetate (EVA) Foam Insert, the ultimate solution for cushioning, protecting, and organizing your valuable items. Our EVA foam inserts are meticulously crafted to provide superior shock absorption, durability, and versatility, making them the ideal choice for a wide range of applications.

Unmatched Cushioning and Protection

Our ethylene-vinyl acetate foam inserts are designed to deliver exceptional cushioning and protection for your items. The unique properties of EVA foam provide excellent shock absorption, ensuring that your products remain safe from impact and vibration. Whether you are transporting delicate electronics, fragile glassware, or valuable collectibles, our EVA foam inserts offer the peace of mind you need.

Versatility in Applications

EVA foam inserts are incredibly versatile and can be used across various industries and applications. They are perfect for use in packaging, ensuring that products are securely held in place and protected during transit. In the world of custom cases, our foam inserts can be precisely cut to fit any shape or size, providing a snug and secure fit for tools, equipment, and other items.

EVA Foam Inserts — Data Sheet

PRODUCT OVERVIEW

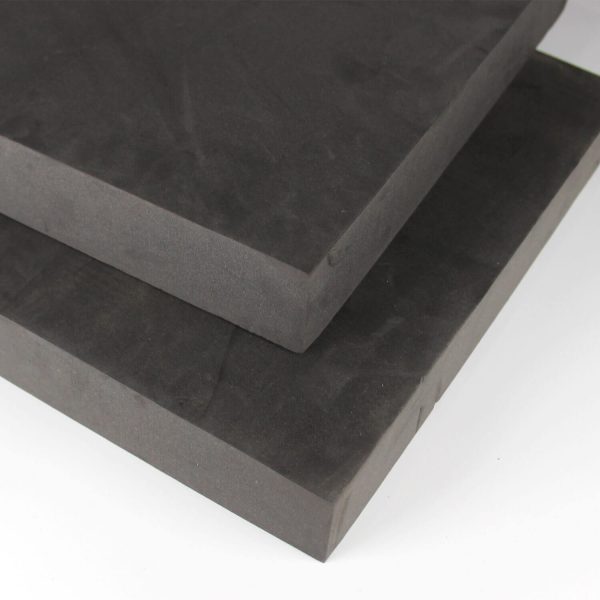

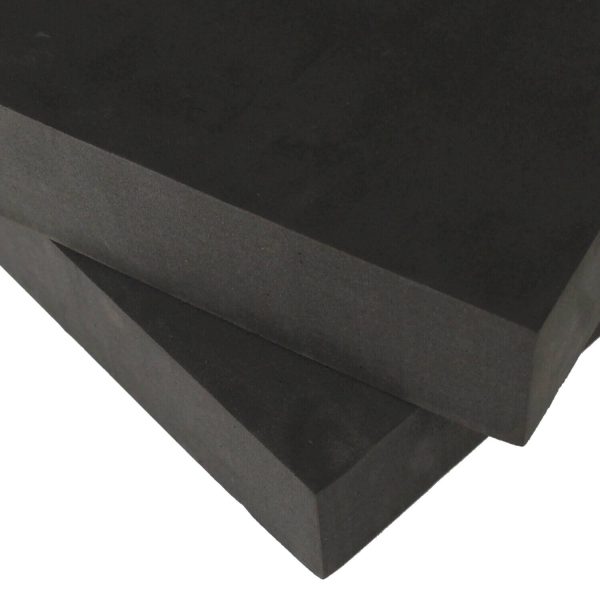

Custom-cut Ethylene-Vinyl Acetate (EVA) foam inserts designed for protective packaging and premium product presentation. Closed-cell, waterproof, non-toxic, and available in odorless/high-elastic formulations to match demanding use cases.

SPECIFICATIONS

Material: EVA (closed-cell)

Features: Waterproof, non-toxic; odorless/high-resilience options available

Density: Customizable (per application)

Hardness: 15 or 25 Shore C standard; other Shore C on request

Thickness: 0.6–60 mm (custom)

Color: Standard black/white; Pantone color-match available

Finish: Smooth, matte, or light texture

Sample: Available

Origin: CN

WHY CHOOSE THESE INSERTS

Precision milling: Tight tolerances from CNC/water-jet/die-cutting for a perfect fit and clean edges.

Presentation upgrade: Crisp pockets and sharp lines elevate unboxing and brand perception.

Cost efficiency: Reduced transit damage/returns; lightweight to control freight costs.

Quick turnaround: Streamlined programming and kitting for fast delivery on repeat or multi-SKU projects.

PERFORMANCE BENEFITS

Impact absorption and vibration damping for sensitive items

Closed-cell moisture barrier; low water uptake

Dimensional stability with low weight

Low odor and skin-safe; suitable for consumer packaging

Easy to cut, route, laminate, print, and clean

TYPICAL APPLICATIONS

Retail & gift: Presentation trays, cosmetics, perfume, wine/spirits sets

Electronics & instruments: Case liners, cavity trays, kitted foam for tools/metrology

Healthcare: Device protection, sample kits (non-sterile packaging)

Automotive/industrial: Component dunnage, WIP trays, returnable packaging

Crafts/branding: Event kits, POS displays, sample boards

PROCESSING & VALUE-ADDS

Converting: CNC routing, water-jet, die-cut, kiss-cut, skiving

Bonding: Contact cement, hot-melt, CA; PSA (peel-and-stick) backers

Lamination: Fabric/film overlays, multi-layer sandwiches, color caps

Marking: Laser/ink printing, numbering for kitted sets

Options: Finger pulls, bevels, radius edges, living hinges, removable plugs

HOW TO SPECIFY (FOR QUOTE/DFM)

CAD/drawing with cavity callouts and quantities per SKU

Sheet/roll size, thickness, and target hardness (Shore C) and/or density

Color (Pantone if needed) and surface finish (smooth/matte/textured)

Tolerances, edge profile, and any removable plugs/finger pulls

Value-adds (PSA, lamination, printing, kitting, bagging)

End-use conditions (humidity, temperature, chemicals) and test needs

QUALITY & COMPLIANCE

Consistent cell structure and thickness control

Batch traceability; material/test documentation available upon request

LOGISTICS

Lead time: ~25 days for standard inserts; add 1–2 weeks for PSA, heat lamination, or complex kitting

Packaging: Flat-pack or nested; export-ready cartons/pallets

FAQ

Q: Can I get samples?

A: Yes—sample sets in various colors/textures are available for fit and finish checks.

Q: Can you adjust softness/firmness?

A: Yes—hardness and density are tunable (e.g., 15 or 25 Shore C, others on request).

Q: Can you build from my CAD file?

A: Yes—provide STEP/DWG/DXF (or dielines); we’ll review for DFM and produce samples quickly.

Q: Is EVA recyclable?

A: EVA is a closed-cell polymer and can be recycled; in-house off-cuts are recycled where possible.