Cosplayers often face challenges with durability and comfort, as their costumes need to withstand the rigors of conventions, photoshoots, and long hours of wear. Our EVA foam sheets are designed to address these concerns, offering superior impact resistance and cushioning for a comfortable, long-lasting cosplay experience.

Crafting your dream cosplay often involves intricate cutting, shaping, and assembly. Our EVA foam sheets are perfectly suited for these tasks, thanks to their easy-to-work-with nature. Whether you prefer hand-shaping with tools or relying on the precision of laser cutting, these sheets will seamlessly integrate into your creative process, allowing you to bring your characters to life with confidence and ease.

EVA Foam Sheets for Cosplay — Data

Material: EVA foam (closed-cell)

Features: Closed-cell, waterproof, non-toxic

Density: Customizable (per request)

Size (block): 1.5 × 2.95 m

Hardness: 15–40° (customizable)

Sample: Available

Thickness: 1–105 mm

Origin: CN

Applications: Cosplay, industrial gasketing, flotation, cushioning

EVA Foam Sheets for Cosplay — Introduction

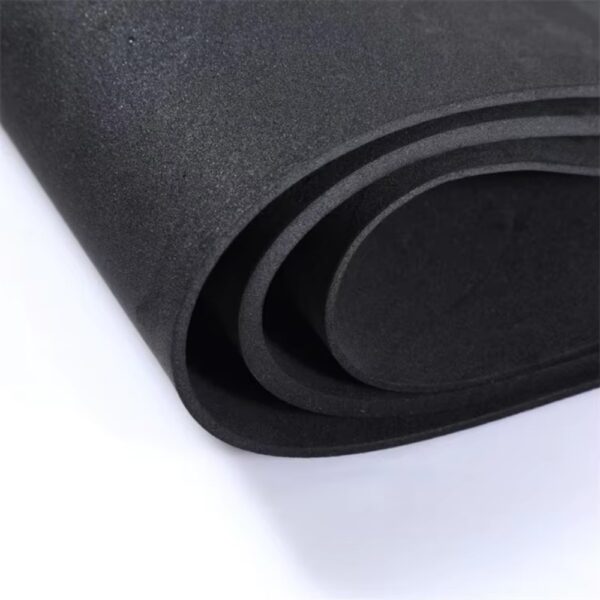

Introducing our factory-direct EVA (Ethylene-Vinyl Acetate) foam sheets for cosplay. Designed for makers who need superior density, flexibility, and durability, these sheets are ideal for armor, helmets, and accessories. A wide color palette—ranging from vibrant brights to metallic tones—lets you match character designs or create custom looks. The foam delivers impact resistance and cushioning for comfort during long conventions and photoshoots. It cuts, sands, heat-forms, and bonds easily, and works with hand tools or compatible CNC/laser setups.

Closed Cell PE Foam — Application Examples

Arts & Crafts: costume foam, cosplay foam, handicraft material, scrapbook decoration

Automotive: sound proofing, car mats, interior padding, carpet underlay, shock absorption

Footwear: outsole, insole, lining

Health Care: orthopedic insoles, arch support, custom supports

Marine: boat decking, helm pad, boat fenders, cooler box mat

Sports & Leisure: 1 m × 1 m sports mats, baby play mat, yoga mat, kneeling mat

FAQ — Closed Cell PE Foam

Q: What is the lead time?

A: Standard rolls and sheets typically ship in about 25 days. Add 1–2 weeks for extras such as PSA backing, heat lamination, or looping.

Q: May I receive samples to test quality?

A: Yes. We offer sample sheets/rolls in various densities, colors, and textures.

Q: Can the foam be made softer or harder?

A: Yes. By adjusting formulation and expansion rates we can tailor softness/firmness, and color-match to your sample or Pantone.

Q: Can Closed Cell PE Foam be recycled?

A: Yes. Closed-cell polyethylene foam can be recycled where facilities exist. We also recycle production offcuts to reduce waste.

Q: Can you develop a product from my CAD file?

A: Yes. With a prototype and CAD that needs only minor revisions, we can typically begin sample production within about 2 weeks.