Marine EVA Foam Sheets: The Ultimate Solution for the Marine Industry

Elevate the durability and comfort of marine applications with our high-quality marine EVA foam sheets. Specifically designed for the marine industry, these foam sheets offer exceptional performance, resilience, and versatility, making them the perfect choice for various marine uses.

Unmatched Durability

Our marine EVA foam sheets are engineered to withstand the harsh conditions of marine environments. They are resistant to UV rays, saltwater, and general wear and tear, ensuring long-lasting performance even in the toughest conditions.

3M 9775 Anti-UV Marine EVA Foam Decking Sheets — Product Data

Closed-cell EVA decking sheets pre-laminated with 3M™ 9775 (300LSE) PSA, engineered for boat decks, swim platforms, and wet-area walkways. Dual-color, UV-stable finish delivers comfort, traction, and easy “peel-and-stick” installation.

Material: EVA, closed-cell

Density: ~185 kg/m³ (custom tunable)

Standard size: 2.4 m × 1.2 m × 6 mm (other sizes/thicknesses on request)

Colors: Any solid or Pantone-matched; dual-color laminations available

Surface options: Brushed / teak lines / diamond / custom textures

Adhesive backing: 3M 9775 (300LSE) high-bond PSA, release liner

Origin: CN

Applications: Boat & RV flooring, swim platforms, pool surrounds, garden decking

Feature set: Anti-UV, non-absorbent, non-slip, easy-clean “teak look” sheets

Anti-UV durability: UV-stabilized top layer helps resist fading and chalking.

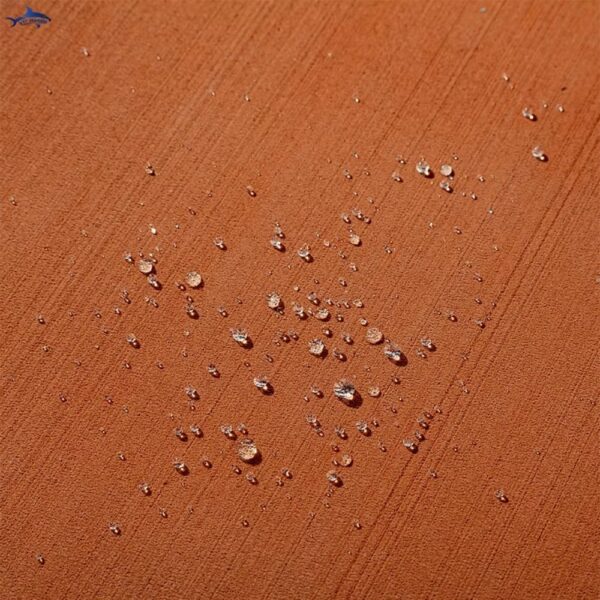

Wet-grip safety: Micro-texture + soft durometer provide confident footing.

Comfort underfoot: Shock-absorbing EVA reduces fatigue on long days afloat.

Closed-cell hygiene: Resists water uptake and staining; quick to rinse clean.

Fast installation: 3M 9775 PSA delivers strong bond to gelcoat, painted aluminum, and sealed composites.

Low maintenance: Soap-and-water clean; no oiling or varnishing.

Thickness: 3/5/6/8/10 mm; single or dual-color (routered reveal)

Groove patterns: Teak lines, diamond, hex, custom logos/laser engraving

Kits from CAD/DXF with CNC routing and part labeling

Edge bevels, radius corners, and alignment markers

Additives on request: extra UV package, heat-reflective pigments

Prep: Substrate must be clean, dry, smooth, and fully cured; solvent-wipe (isopropyl alcohol 70–90%) and lint-free cloth.

Dry fit: Position panels; mark reference lines.

Bond: Peel liner gradually, lay from one edge, and roll-press firmly (soft rubber roller).

Seams/edges: Maintain tight seams; avoid stretching during placement.

Cure: Light use after ~24 h; full bond develops over 72 h (≥15 °C/59 °F ambient; avoid heavy washdowns until cured).

Rinse after use; clean with mild boat soap and soft brush.

Avoid harsh solvents, bleach, or stiff wire brushes.

For scuffs: citrus-based cleaner or isopropyl alcohol spot clean.

Cover or ventilate when moored long-term to reduce heat build-up.

Lead time: About 25 days for standard sheets; add 1–2 weeks for PSA lamination, dual-color routing, or kit-cutting.

Samples: Available—multiple textures, colors, and thicknesses.

Hard/soft feel: Compound and expansion can be tuned to your preference.

Recyclability: EVA closed-cell foam can be recycled where facilities exist; production offcuts are recycled in-plant.

From CAD: Yes—provide CAD/DXF and notes; sample kits typically start within 2 weeks after minor revisions.

Vessel model/areas and total coverage (m²)

Thickness & color scheme (single/dual-color)

Pattern (teak line spacing, diamond, logo marks)

Substrate type (gelcoat, painted Al, composite) and surface condition

Kit-cut vs. full sheets; seam layout

Delivery timeline and packaging needs

Notes: “3M” and “3M 9775” are trademarks of 3M. SeaDek® is a registered trademark of its owner and is referenced descriptively only.