Superior Polyethylene Foam: The Ideal Choice for the Marine Industry

Discover the exceptional benefits of our polyethylene foam, specifically designed for the marine industry. Renowned for its durability, buoyancy, and resistance to harsh marine conditions, this high-performance foam is the ultimate solution for a variety of marine applications.

Material: Closed-cell Polyethylene (PE) Foam

Feature: Thick-gauge PE sheets (including 50 mm)

Density: Customizable, as per customer request

Size: 1.5 × 52.95 m per block (custom sizes available)

Hardness: 15–40 degree (or customized)

Sample: Available

Thickness: 1–105 mm

Origin: CN

Experience unmatched performance with our wholesale high density thick polyethylene foam, tailored for the marine industry. This premium foam offers exceptional durability, buoyancy, and resistance to harsh conditions, making it ideal for a wide range of marine applications.

Unmatched Buoyancy and Stability

Our polyethylene foam provides superior buoyancy for flotation devices, life vests, and buoyancy aids. Its closed-cell structure ensures consistent buoyancy and stability in water—essential for safety and reliability in marine environments.

Exceptional Durability

Engineered to withstand saltwater, UV exposure, and physical impacts, our high-density thick PE foam resists wear and tear to deliver long-lasting performance and protection.

We supply and manufacture PE foam for hundreds of different industries. See below some examples of applications:

Arts and Crafts

Costume foam

Cosplay foam

Handicraft material

Scrapbook decoration

Automotive

Sound proofing

Car mats

Interior padding

Carpet underlay

Shock absorption

Footwear

Outsole

Insole

Lining

Health Care

Orthopedic insoles

Arch support

Custom supports

Marine

Boat decking

Helm pad

Boat fenders

Cooler-box mat

Sports & Leisure

1 m × 1 m sports mats

Baby play mat

Yoga mat

Kneeling mat

What is the lead time for PE foam sheets?

For standard rolls and sheets, the typical lead time is about 25 days for shipping. If you require additional services—such as PSA backing, heat lamination, or looping—the lead time may extend by 1–2 weeks.

May I receive samples to test the quality?

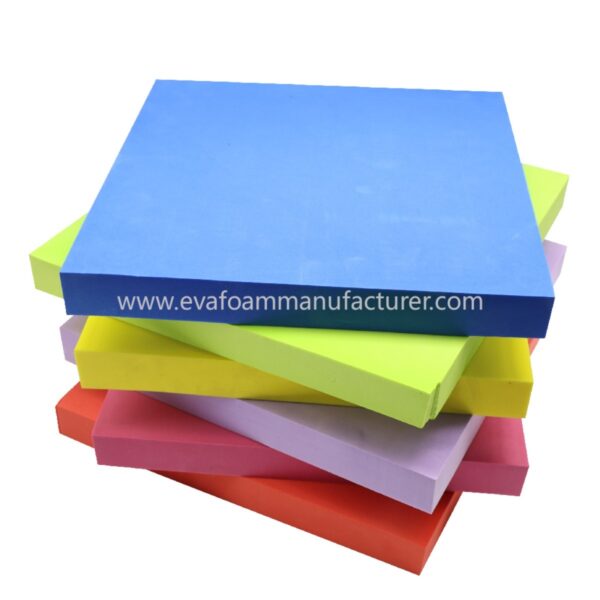

Yes. We offer sample PE foam sheets/rolls in various colors and textures upon request.

Can PE foam be made softer or harder?

Yes. By adjusting compounds and expansion rates, we can produce PE foam with different softness or firmness levels. We can also color-match to your sample or Pantone reference.

Can PE foam be recycled?

PE foam can be recycled where facilities exist. In our facility, we recycle leftover PE offcuts to minimize waste and support sustainability.

Can you develop a PE foam product from my CAD file?

Yes. If you have a prototype and a CAD file ready, and only minor revisions are needed, we can typically initiate sample production within about 2 weeks.