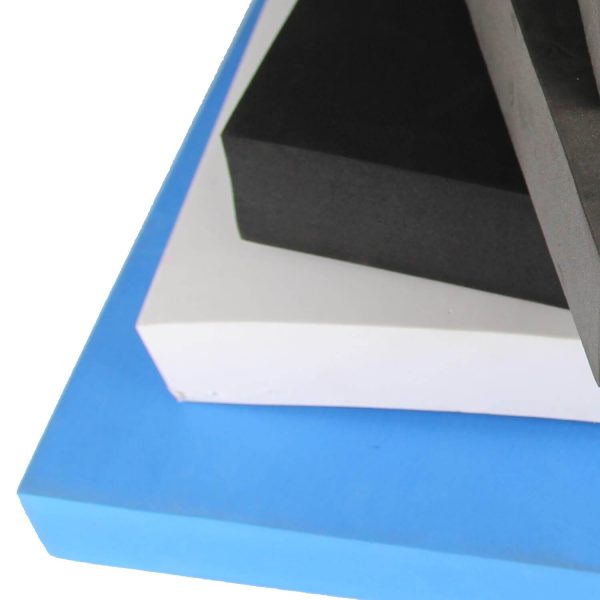

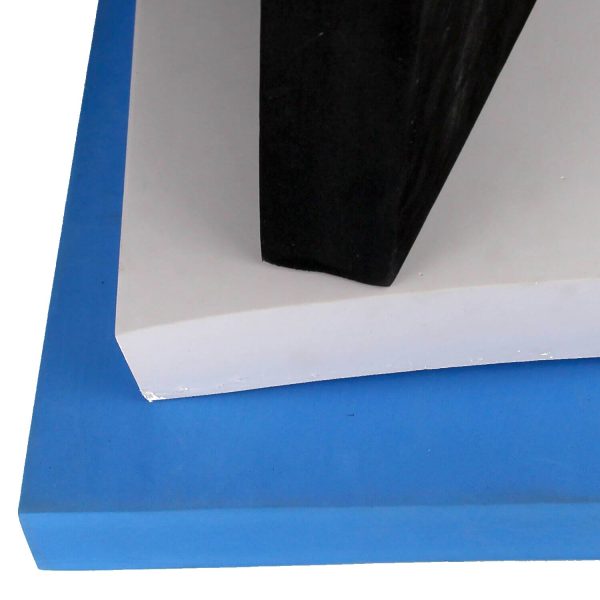

EVA foaming sheet, also known as Ethylene-Vinyl Acetate foam, is a closed-cell material known for its lightweight, durable, and flexible properties. It is extensively used in various sectors due to its ability to absorb impact, resist water, and corrosion. This foaming sheet has a broad range of applications, from crafting and sports equipment to industrial uses and footwear manufacturing. Its versatility and easy-to-use nature make it a popular choice amongst various industries.

Factory High-Quality Sheet-Foaming EVA Materials — Data Sheet

PRODUCT OVERVIEW

Factory-made ethylene-vinyl acetate (EVA) foam sheets engineered for consistent cushioning, flexibility, and durability. Lightweight and easy to convert, they’re suited to packaging, sports gear, footwear components, crafts, and more. Tight in-process controls deliver stable thickness, density, and color across every batch.

CORE SPECIFICATIONS

Material: EVA (Ethylene-Vinyl Acetate), closed-cell

Grades: A+, A, B, C

Density: Customizable (per application)

Thickness: Customizable

Color: Multicolor options; Pantone color-matching available

Sample: Available

Origin: CN

VALUE HIGHLIGHTS

Reliable cushioning and shock absorption for impact protection

Flexible, lightweight, and easy to fabricate; reduces shipping weight

Closed-cell structure: moisture resistant and easy to wipe clean

Consistent quality: stable density, thickness, and color from sheet to sheet

Broad customization: size, color, surface texture, and add-on services

TYPICAL APPLICATIONS

Arts & Crafts: costume foam, cosplay, props, scrapbook décor

Footwear: outsoles, midsoles, insoles, liners

Packaging: case inserts, trays, impact pads, presentation kits

Automotive: sound-damping pads, interior padding, anti-rattle gasketing

Health Care: orthotic blanks, arch supports, custom padding

Marine: boat decking pads, cooler liners, fenders

Sports & Leisure: 1 m × 1 m mats, yoga/kneeling mats, play mats

CONVERTING & SERVICES

Cutting: die-cutting, kiss-cutting, CNC routing, water-jet

Forming: heat bending/thermoforming for 3D shapes

Bonding: hot-melt, contact adhesive, cyanoacrylate; PSA (peel-and-stick) backing available

Lamination: fabric/film overlays, multi-layer builds, color-cap layers

Finishing: bevels/radii, emboss textures, logos/printing, kitting and packaging

PERFORMANCE NOTES

Shock and vibration damping with resilient rebound

Closed-cell waterproof barrier; resistant to incidental spills and humidity

Good thermal and acoustic buffering

Low odor; consumer-safe formulations available on request

HOW TO SPECIFY (FOR QUOTES)

Sheet size or blank size (and any nest layout requirements)

Target density and thickness range

Color (Pantone code if needed) and preferred surface finish/texture

Converting method (die-cut/CNC/water-jet) and dimensional tolerances

Add-ons (PSA backing, lamination, printing, edge finish, kitting)

End-use conditions (temperature/humidity/chemicals) and test needs

LOGISTICS

Lead time: ~25 days for standard sheets; add 1–2 weeks for PSA, heat lamination, or looping/complex builds

Packing: flat sheets or rolls; export-ready cartons/pallets

FAQ

Q: May I receive samples to test quality?

A: Yes. Sample sets in various colors/textures are available for review and fit checks.

Q: Can the material be made softer or harder?

A: Yes. Density and feel are adjustable to meet your cushioning or firmness targets.

Q: Is EVA foam recyclable?

A: EVA is a closed-cell polymer that can be recycled; we recycle in-house off-cuts to minimize waste.

Q: Can you manufacture from my CAD file?

A: Yes. Share your CAD/dielines (STEP/DWG/DXF). We’ll review for manufacturability and produce samples quickly.