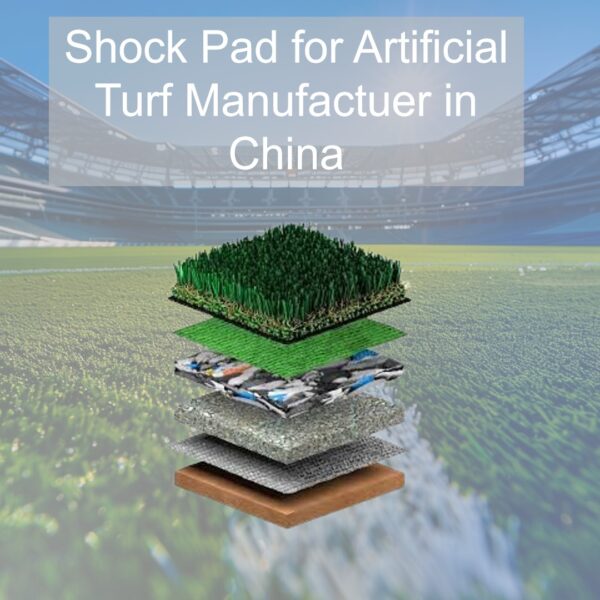

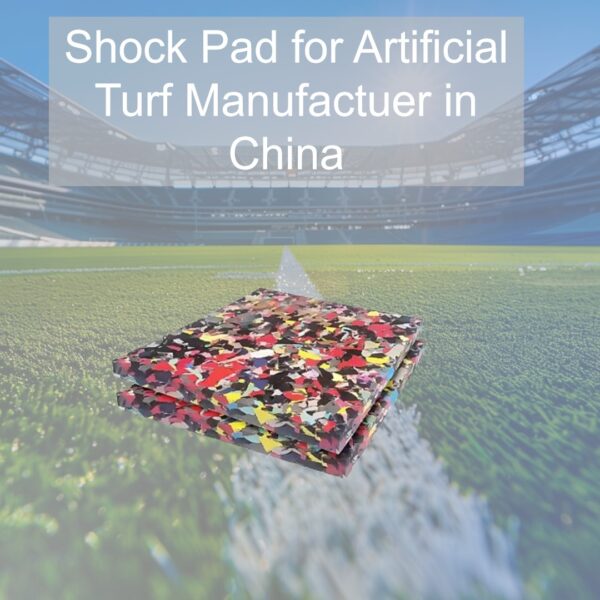

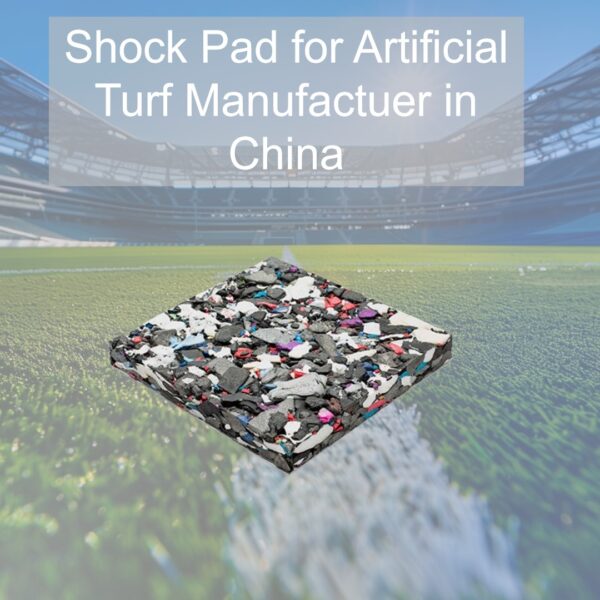

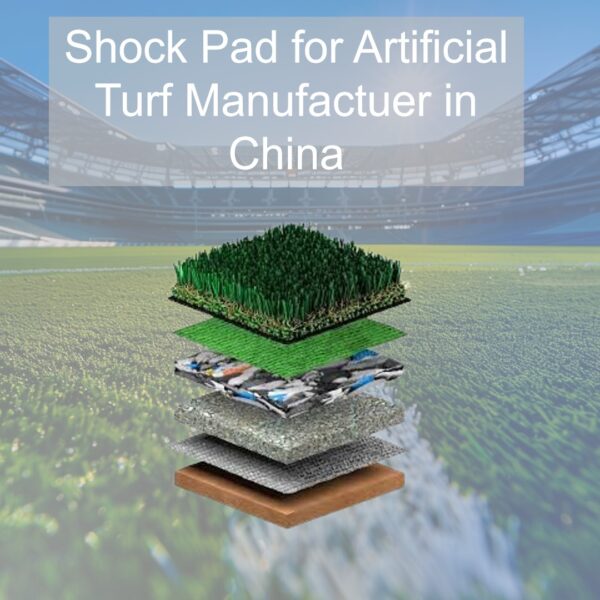

Introducing our Eco-friendly turf shock pad under artificial turf layer, a premium underlayer designed to revolutionize the performance of your artificial turf. Whether you’re upgrading a sports field, playground, or backyard, this shock pad provides unparalleled shock absorption, ensuring safety and comfort for all users. Engineered with advanced technology and eco-friendly materials, our shock pad stands out as the top choice for creating a high-performance and sustainable turf system.

Eco-Friendly Turf Shock Pad Under Artificial Turf Layer — Product Data

PRODUCT OVERVIEW

Closed-cell EVA underlayment engineered for synthetic turf systems. Delivers consistent impact attenuation, player comfort, and long-term resilience with sustainable material options for sports fields, playgrounds, and landscaped areas.

TECHNICAL SPECIFICATIONS

Material: EVA (closed-cell foam)

Feature: Turf shock pad (sheet or roll)

Applications: Artificial grass, playground padding, football/soccer fields, floor-mat base, packaging spacers

Density: Customizable to project targets

Thickness: As per customer request

Color: Custom or Pantone-matched

Origin: CN

KEY BENEFITS

Exceptional Shock Absorption: Helps reduce peak impact forces to protect joints and minimize injury risk.

Eco-Friendly Options: Available with recycled EVA content and in-plant offcut recycling to reduce waste.

Weatherproof & Drainage-Ready: Closed-cell structure resists water uptake; optional perforation/drainage channels support fast runoff.

Durable Resilience: Maintains thickness and performance under repeated loads; low compression set.

Comfort & Acoustics: Damps vibration, reduces field noise, and improves underfoot feel.

Fast Installation: Lightweight, clean cuts, and compatible with common turf adhesives/tapes.

TYPICAL APPLICATIONS

Sports: Football/soccer, multi-sport training areas, indoor arenas

Playgrounds: Under-turf safety layers in fall-attenuation zones

Landscaping: Residential/commercial lawns, pet areas, rooftops/terraces

Recreation & Fitness: Multi-use zones where comfort and protection matter

OPTIONS & CUSTOMIZATION

Density tuning for target performance (e.g., comfort/HIC/G-max objectives)

Thickness profiles to meet site-specific fall-height or feel goals

Perforated or channeled versions for drainage (project-dependent)

Sheet/roll widths and lengths to minimize seams and waste

Bonding approach: loose-lay with seam tape, perimeter-bond, or full-bond

Color accents and branding cuts (on request)

BASIC INSTALLATION (UNDER TURF)

Base Prep: Grade, compact, and level per turf designer’s spec; confirm drainage plan.

Underlayment: Unroll panels and allow to relax flat; butt seams snugly (no overlaps).

Seaming: Tape or bond seams as specified; maintain a smooth, continuous surface.

Turf: Lay synthetic turf, seam per manufacturer instructions, and secure perimeters.

Infill & Finish: Add specified infill, brush to height, and verify surface evenness/drainage.

CARE & MAINTENANCE

Follow the turf manufacturer’s cleaning schedule; keep debris off the surface.

Inspect seams, edges, and high-traffic zones periodically.

Store spare material flat, dry, and out of direct UV.

FREQUENTLY ASKED QUESTIONS

Lead time

Standard rolls/sheets typically ship in ~25 days. Allow +1–2 weeks for services like PSA backing, heat-lamination, custom perforation, or kitted field sets.

Samples

Yes. Sample kits can include multiple densities, thicknesses, and finishes.

Soft or firm options

We adjust compounding/expansion to achieve your desired firmness and safety performance.

Recyclability

EVA closed-cell foam can be recycled where facilities exist; we recycle production offcuts to reduce waste.

Build from CAD

Yes. Provide CAD/DXF and layout notes; with minor revisions, sample production can typically begin within two weeks.

ORDERING CHECKLIST

Project type & coverage area

Target performance (e.g., comfort/HIC/G-max)

Preferred density and thickness range

Drainage needs (solid, perforated, or channeled)

Roll/sheet sizing and seam plan

Bonding method (loose-lay, perimeter-bond, full-bond)

Color/branding requirements and timeline

Share the checklist details to receive a tailored specification and quote.