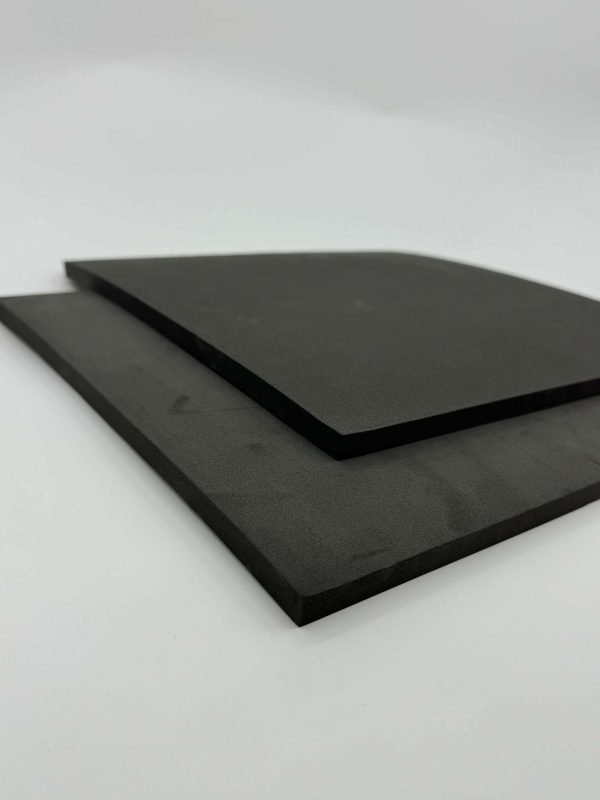

Introducing our anti-slip EVA sheets for footwear – crafted for comfort, safety, and performance. Made with high-quality EVA, our sheets provide reliable traction and stability on any surface. Elevate your footwear designs with our durable and innovative anti-slip solution.

EVA Foam Sheet — Data Sheet

PRODUCT OVERVIEW

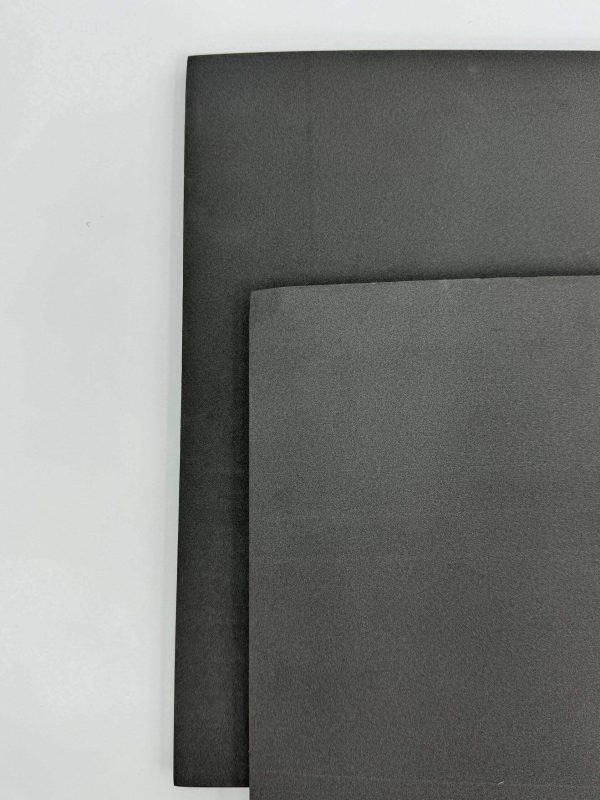

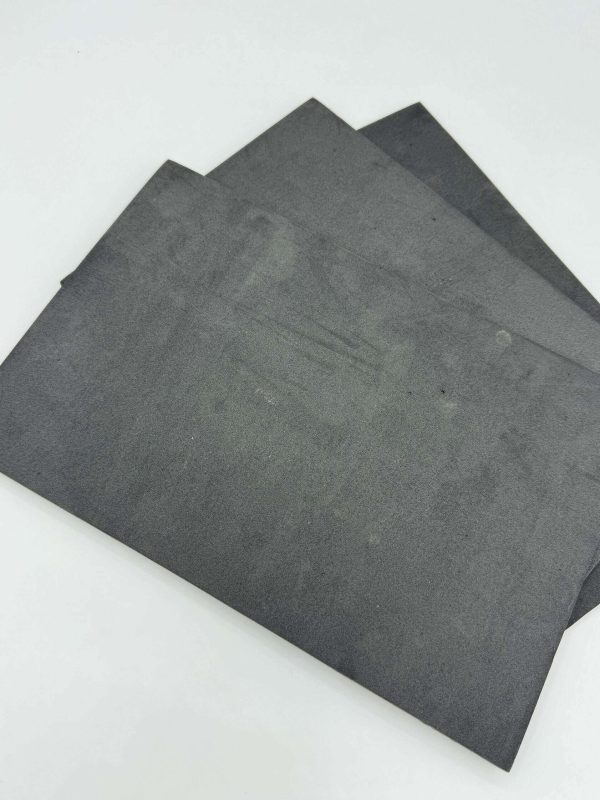

Soft, anti-slip EVA (Ethylene-Vinyl Acetate) sheets engineered for footwear and general cushioning uses. Available in multiple grades with customizable color, hardness, and thickness.

SPECIFICATIONS

Material: EVA (closed-cell)

Grades: A+, A, B, C

Hardness: 18 Shore C, 25 Shore C (other Shore C values on request)

Thickness: Customizable

Color: Multi-color options; Pantone matching available

Applications: Footwear/slippers, cosplay, protective packaging

Sample: Available

Origin: China (CN)

KEY FEATURES (FOOTWEAR FOCUS)

Anti-slip surface: Textured treatment delivers high wet- and dry-traction for safer slippers, sandals, poolside and shower footwear.

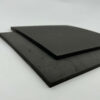

Superior comfort: Closed-cell cushioning absorbs shock and reduces foot fatigue.

Durable finish: Anti-slip treatment and foam integrity resist wear, maintaining grip and comfort over extended use.

Design flexibility: Wide choices in thickness, color, and textures for branding and style alignment.

PERFORMANCE BENEFITS

Impact absorption and rebound for comfort and product protection

Water-resistant, closed-cell structure with low water uptake

Light weight with good dimensional stability

Low odor, non-toxic; suitable for consumer products

Easy to cut, shape, heat-form, print, and laminate

PROCESSING & CONVERTING

Cutting/Forming: Knife, die-cut, water-jet, CNC; heat-formable for curves

Bonding: Contact cement, hot-melt, cyanoacrylate (CA), double-sided PSA liners

Surface Options: Smooth, matte, embossed/textured anti-slip patterns

Value-Add: PSA (peel-and-stick), fabric/film lamination, kiss-cutting, kitted sets

TYPICAL APPLICATIONS

Footwear: Insoles, midsoles, outsoles for slippers/sandals, heel pads

Sports/Leisure: Pool and bath mats, yoga and fitness accessories

Packaging: Case liners, protective inserts, shock-absorbing pads

Crafts/Cosplay: Armor, props, patterns, templates

QUALITY & COMPLIANCE

Consistent cell structure and thickness tolerance

Batch traceability; material certifications available on request

LOGISTICS

Lead time: ~25 days for standard sheets/rolls

(add 1–2 weeks for PSA, heat lamination, or special converting)

Packing: Flat sheets or rolls; export-ready cartons/pallets

HOW TO SPECIFY (FOR QUOTE/DFM)

Provide:

Thickness and sheet/roll dimensions

Target hardness (e.g., 18 or 25 Shore C) and any density preference

Color (Pantone code if needed) and surface texture (smooth or anti-slip pattern)

Converting needs (die-cut, PSA backing, lamination, kits)

End-use environment (wet exposure, temperature range, load)

FAQ

Q: What is the lead time?

A: About 25 days for standard items; add 1–2 weeks for PSA, heat lamination, or looping.

Q: Can I get samples?

A: Yes. Samples are available in multiple colors and textures for evaluation.

Q: Can the foam be made softer or harder?

A: Yes. Hardness and density can be tuned (e.g., 18–25 Shore C and beyond) by adjusting formulation and expansion.

Q: Is EVA foam recyclable?

A: EVA is a closed-cell polymer and can be recycled; production off-cuts are recycled in-house where possible.

Q: Can you make from my CAD file?

A: Yes. With a prototype and CAD, samples can usually be produced quickly (subject to minor DFM adjustments).