Introducing our factory direct poland market foam EVA foam slipper sheet- Experience unmatched comfort and quality. Tailored to the unique demands of the Polish market, our EVA slipper sheets are perfect for manufacturers looking to create top-notch slippers that cater to the preferences of Polish consumers. Designed for ease of use in manufacturing, our EVA slipper sheets are simple to cut, shape, and mold, making the production process more efficient and cost-effective. Whether you’re employing traditional methods or advanced manufacturing techniques, our EVA foam sheets will seamlessly integrate into your production line.

Factory-Direct EVA Slipper Sheet (Poland Market) — Product Data

Closed-cell EVA foam sheets engineered for slipper and flip-flop soles. Lightweight, resilient, and easy to convert—optimized for high-volume production popular with manufacturers serving the Polish market.

Material: EVA (closed-cell foam)

Applications: Slipper/flip-flop soles, midsoles, sandals; also luggage pads, swim boards, floor mats, packaging

Density: Customizable to project targets

Hardness: 25–80° (Shore scale as specified)

Thickness: As requested

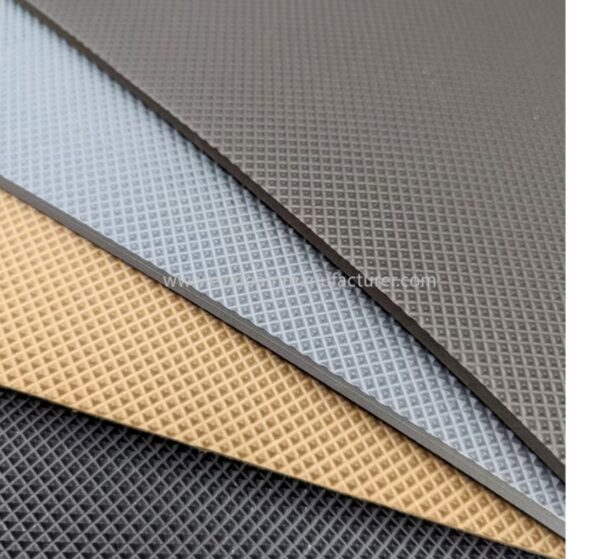

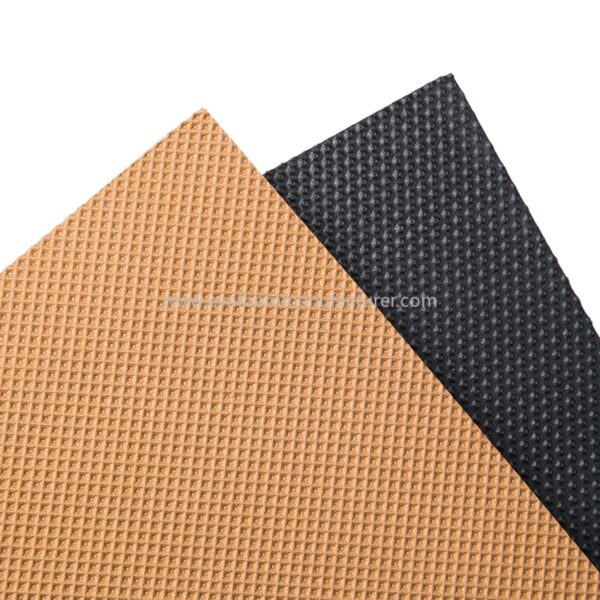

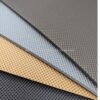

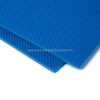

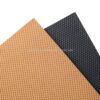

Patterns: Multiple anti-slip textures available

Color: Any custom or Pantone-matched

Origin: CN

Formats: Sheets or pre-cut kits

Comfort & rebound: Soft step-in feel with durable cushioning.

Wear & water resistance: Closed-cell structure resists water uptake and daily abrasion.

Secure traction: Textured grains improve grip on wet and dry surfaces.

Stable processing: Low compression set; consistent performance through press and trim.

Conversion-friendly: Cuts, die-cuts, mills, and heat-forms cleanly; bonds well with common footwear adhesives.

Brandable: Color, texture, and laser/emboss logo options.

Density/durometer tuning for target comfort & durability

Single/dual-color laminate looks; fabric or rubber toppers

Sheet sizes tailored to your nest to reduce waste

PSA (adhesive) backing for peel-and-stick assemblies (on request)

CNC kit-packing from CAD/DXF with part numbering

Footwear: Slipper soles, flip-flops, sandals, indoor/outdoor house shoes

Accessories: Luggage inserts, yoga/kneeling pads, protective padding

Cutting: Press die-cut, kiss-cut, waterjet, or CNC routing

Forming: Cold or hot press; thermoformable within recommended window

Adhesives: PU/reactive hot-melt/contact cements; roughen & clean bonding faces before assembly

Wipe clean with mild soap/water; avoid harsh solvents/bleach

Store flat, dry, and out of direct UV; keep packaged until use to prevent dust pickup

Lead time: Standard sheets typically ship in ~25 days. Add 1–2 weeks for PSA backing, heat-lamination, special textures, or kit sets.

Samples: Yes—kits available in multiple densities, thicknesses, and textures.

Soft/firm options: Achieved via compounding and expansion control to your target durometer.

Recyclability: EVA closed-cell foam can be recycled where facilities exist; in-plant offcuts are recycled to minimize waste.

From CAD: Provide CAD/DXF and layout notes; with minor revisions, sample production can usually begin within two weeks.

Target product (slipper style) and monthly volume

Density & hardness range; thickness per size

Texture/grain selection and color/Pantone

Sheet size & nesting plan (or request kit-cut parts)

Bonding method and any laminations/PSA

Branding (logo emboss/laser) and packaging needs

Required documentation (e.g., RoHS/REACH statements) and delivery timeline

Share the checklist and we’ll return a tailored spec, cut plan, and quotation for your Poland programs.