Custom boat carpet: Enhance Your Boating Experience.

Constructed from high-quality materials, our custom boat carpet is built to withstand the harsh marine environment. It is resistant to UV rays, moisture, mold, and mildew, ensuring long-lasting performance and maintaining its appearance season after season.

Our custom boat carpet is designed for easy installation, allowing you to upgrade your boat’s interior quickly and efficiently. It is also low-maintenance, requiring minimal cleaning to keep it looking fresh and vibrant.

Bulk Buy 3M-Adhesive EVA Boat Decking (SeaDek-Comparable) — Product Data

Closed-cell EVA marine decking sheets with factory-applied 3M™ pressure-sensitive adhesive (PSA). Designed as a comfortable, non-slip, low-maintenance alternative to traditional boat carpet for cockpits, swim platforms, and interior/exterior decks.

Material: EVA (closed-cell foam)

Density: ~185 kg/m³

Standard size: 2.4 m × 1.2 m × 6 mm (custom sizes available)

Colorways: Any solid color or Pantone-matched; double-color surface treatment supported

Thickness: Per request (6 mm standard)

Adhesive: 3M™ PSA backing (peel-and-stick)

Origin: CN

Use cases: Boat & RV flooring, swim platforms, pool surrounds, garden paths

Peel-and-stick install: 3M™ PSA speeds layout and bonding—no secondary glue needed.

Comfort & safety: Cushioned underfoot with reliable wet/dry traction.

Marine-ready: Closed-cell (low water uptake), easy to rinse clean, UV-resistant blends available.

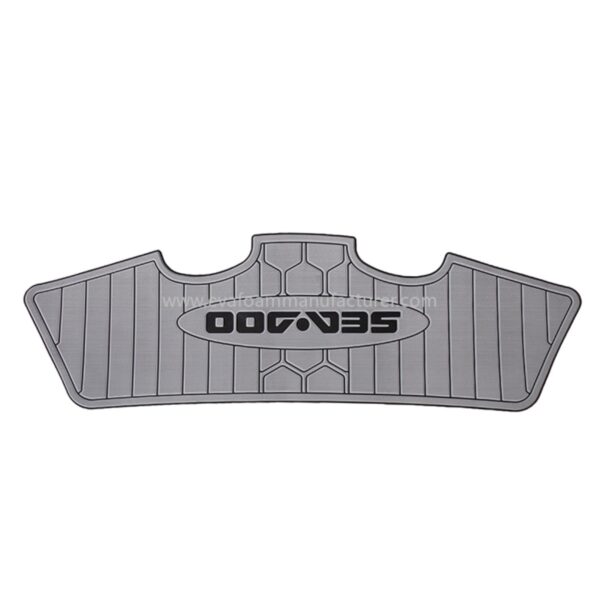

Aesthetic control: Double-color options for routed logos, borders, or patterns.

Quiet & protective: Damps vibration and helps protect gelcoat from scuffs.

Color & texture selection (solid or dual-color stacks)

Sheet/kit sizing to minimize seams and offcuts

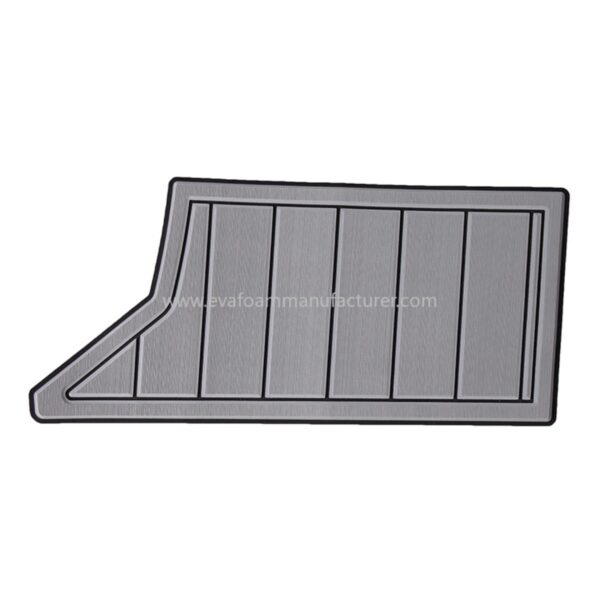

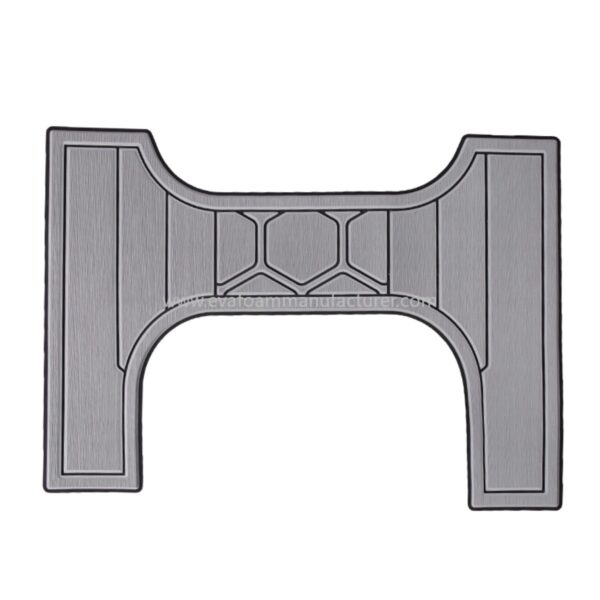

CNC routing for logos, faux-teak lines, or puzzle-fit kits from CAD/DXF

Edge chamfers, radius corners, and part numbering for install sequencing

Center consoles, bass boats, pontoons, PWCs

Helm stations, gunwales, cockpit soles, hatches

Swim platforms, steps, lockers, cabin entries

RV slide-outs and toy-hauler bays

Prep: Dry fit pieces. Clean substrate (de-wax/de-grease) and ensure it’s dry, smooth, and above 15 °C (59 °F).

Prime (if specified): Use compatible surface prep/primer on low-energy plastics or aged gelcoat.

Bond: Peel small sections of liner, align, and lay with light tension. Work outward to avoid bubbles.

Roll: Firmly roll with a J-roller (especially edges/corners).

Cure: Keep dry and unloaded for 24–48 h before service; avoid pressure washing for 72 h.

Rinse regularly; spot clean with mild soap and soft brush.

Avoid harsh solvents/oxidizers; use marine-safe cleaners.

For stubborn stains, use diluted APC and gentle agitation; rinse thoroughly.

Lead time: About 25 days for standard sheets; add 1–2 weeks for PSA variations, heat-lamination, special kitting, or custom routing.

Samples: Yes—sample packs cover multiple colors, textures, and densities.

Soft/firm feel: We tune compounding/expansion to your requested firmness.

Recyclability: EVA closed-cell foam can be recycled where facilities exist; our offcuts are recycled in-plant.

Build from CAD: Provide CAD/DXF and notes; with minor edits we can usually start sample production within 2 weeks.

About “SeaDek same quality”: Product is engineered for comparable feel and performance; not made by or affiliated with SeaDek® (name used for reference only).

Boat make/model, area drawings, and total m²

Colorway(s): single or double-color; any logo routing

Target thickness and feel (firm/standard/soft)

Kit vs. full sheets; seam layout preferences

Adhesive/primer requirements based on substrate

Timeline and shipping terms

SeaDek® is a registered trademark of Hyperform, Inc. All references are for compatibility/comparison only.