Orthotic EVA Foam: Superior Support for the Sports and Athletics Industry

Elevate performance and comfort in the sports and athletics industry with our high-quality Orthotic EVA Foam. Designed to provide exceptional cushioning, support, and durability, this material is perfect for creating custom orthotics that enhance athletic performance and reduce injury risk.

Polyethylene (PE) Foam — Product Data

Closed-cell polyethylene foam sheets & rolls designed for lightweight cushioning, protection, and insulation. Available in non-crosslinked (PE) and crosslinked (XLPE) grades to match performance, finish, and conversion needs across packaging, sports/leisure, marine, construction, and medical accessories.

Material: Polyethylene foam (closed-cell); PE or XLPE

Density: Customizable to project targets

Thickness: As requested (typical 1–100 mm)

Color: Any custom color or Pantone-matched

Surface: Smooth or embossed textures; printable films available

Formats: Sheets or rolls; skived or molded; kit-cut parts

Origin: CN

Impact protection & comfort: Excellent shock absorption with resilient rebound.

Closed-cell performance: Low water uptake, buoyant, easy to wipe clean.

Thermal & acoustic damping: Useful for insulation, HVAC wraps, and case lining.

Lightweight yet tough: Low compression set for durable, repeatable performance.

Conversion-friendly: Cuts, die-cuts, routs, waterjets, and heat-forms cleanly.

Aesthetic options: Embossed grains/patterns and color branding.

Grade selection: PE vs. XLPE (finer cell, smoother skin)

Density tuning for target cushioning/stiffness

PSA (adhesive) backing, kiss-cut parts, peel-and-stick kits

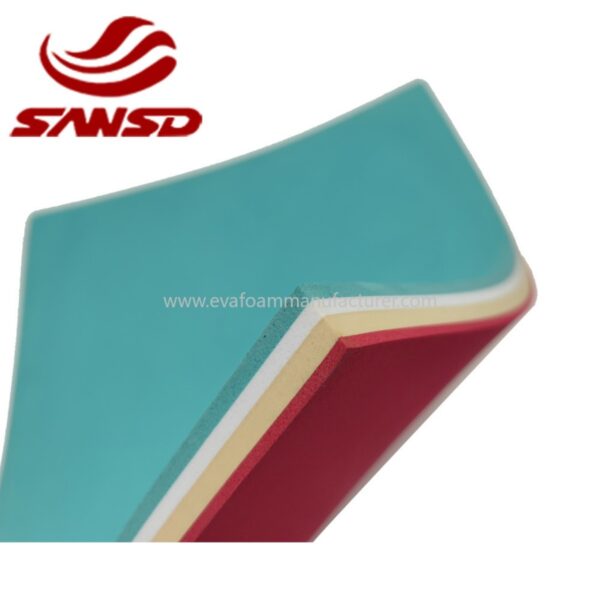

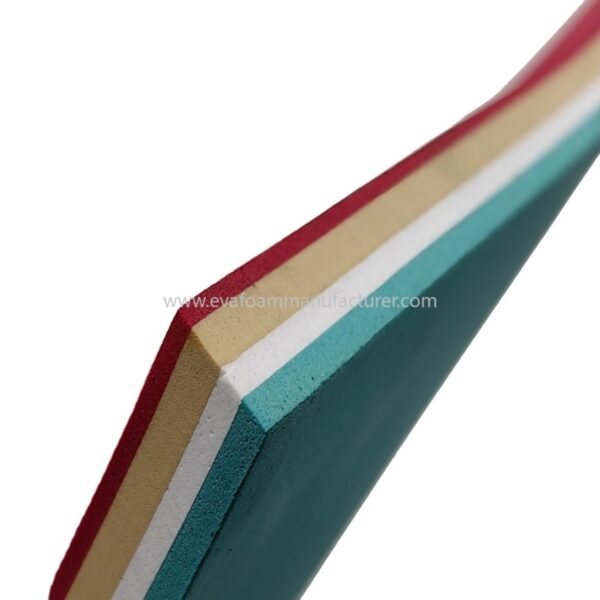

Laminations: fabrics/mesh, films (PE/PP/TPU), foil, hook-compatible toppers

Functional additives: ESD/anti-static, UV-stabilized, flame-retardant (project-dependent)

CNC kit-packing from CAD/DXF, part numbering, logo emboss/print

Compliance docs on request (e.g., RoHS/REACH, formamide reporting)

Protective packaging: Case inserts, end caps, appliance & electronics cushions

Sports & leisure: Yoga/kneeling mats, padding, fitness blocks

Marine & outdoor: Flotation aids, deck padding, equipment bumpers

Construction: Expansion joint filler, pipe lagging, thermal/acoustic underlay

Automotive: NVH pads, liners, cargo inserts

Medical/orthotic accessories: Padding, liners, posting blocks (spec-grade XLPE)

Cutting: Knife, die-cut, waterjet, or CNC routing

Forming: Heat-formable within recommended temperature window

Bonding: Contact cements, PU adhesives, hot-melt, or factory PSA

Surface prep: Clean, dust-free; light solvent wipe if adhesive-compatible

Wipe with mild soap/water; avoid harsh solvents/bleach

Store flat, dry, and out of direct UV; specify UV-stabilized grades for sun exposure

Keep packaged until install to limit dust and scuffing

Lead time: Standard sheets/rolls typically ship in ~25 days; add 1–2 weeks for PSA lamination, embossing, special additives, or kit sets.

Samples: Yes—sample kits in multiple densities, thicknesses, and textures.

Soft/firm options: Delivered via density/grade and expansion control.

Recyclability: PE foam is recyclable where facilities exist; crosslinked grades may require specialized streams. In-plant offcuts are recycled to minimize waste.

Build from CAD: Provide CAD/DXF and layout notes; with minor revisions, sample production can usually begin within two weeks.

End use and total coverage (m²) or part count

Grade: PE or XLPE; target density and thickness

Texture/finish and color (Pantone if needed)

Functional needs: ESD, FR, UV, thermal/acoustic targets

PSA backing or lamination requirements

Kit-cut parts vs. full sheets; file format (CAD/DXF)

Compliance/testing needs and delivery timeline

Share the checklist and we’ll recommend the right PE foam grade, finishes, and build for a fast, accurate quotation.