Seadek EVA Foam Sheet Material: Ultimate Comfort and Durability for Marine Applications.

Upgrade your marine vessel with our premium Seadek EVA Foam Sheet Material, designed to provide superior comfort, durability, and safety. Ideal for various marine environments, this foam sheet enhances both the functionality and aesthetics of your boat.

Seadek Same Quality EVA Foam Sheet Material — Product Data

Product Overview

High-performance, closed-cell EVA foam sheets engineered for boat and yacht decking. Delivers dependable wet traction, comfort, and weather resistance with options for custom color, size, and finish.

Technical Specifications

Material: EVA (closed-cell)

Density: 120 kg/m³

Standard Sizes: 29×29 cm, 31×31 cm, 62.5×62.5 cm, 1×1 m (custom sizes available)

Thickness: As requested (common: 3 / 5 / 6 / 8 mm)

Colors: Any color or Pantone match

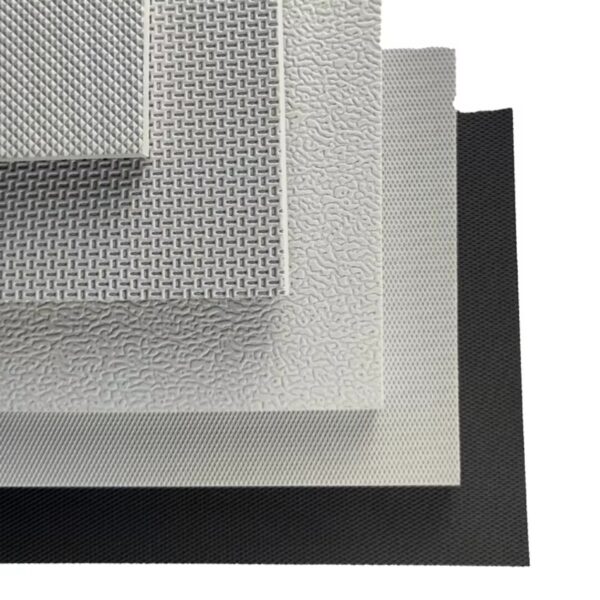

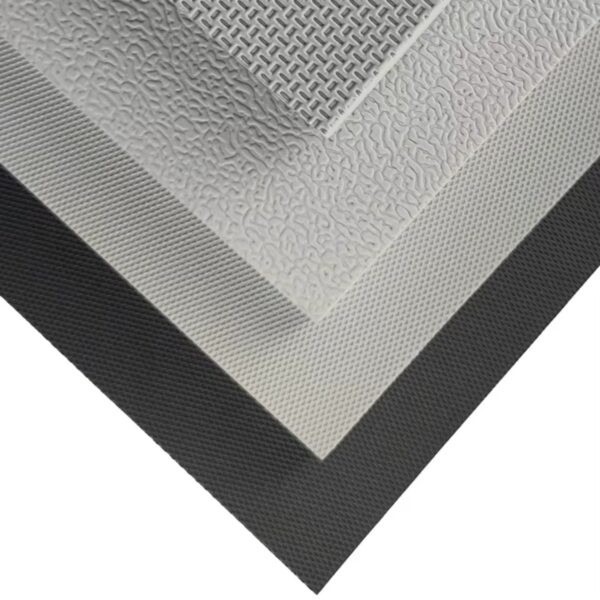

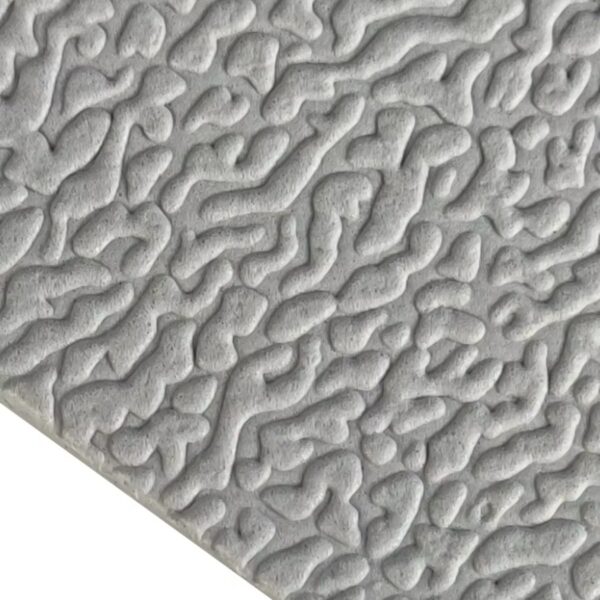

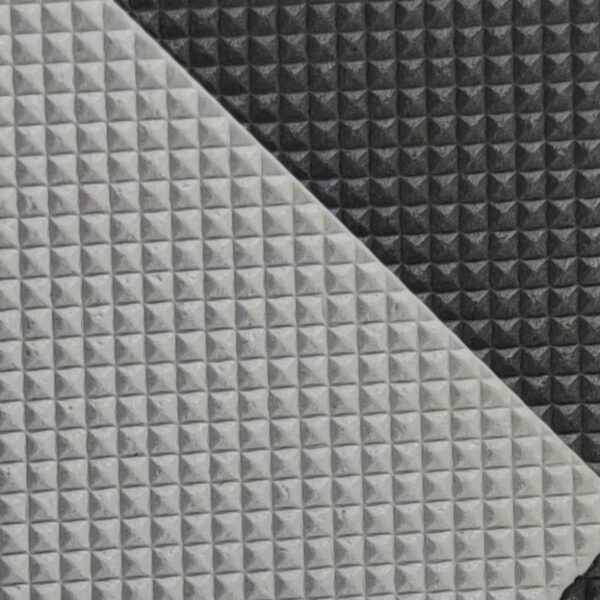

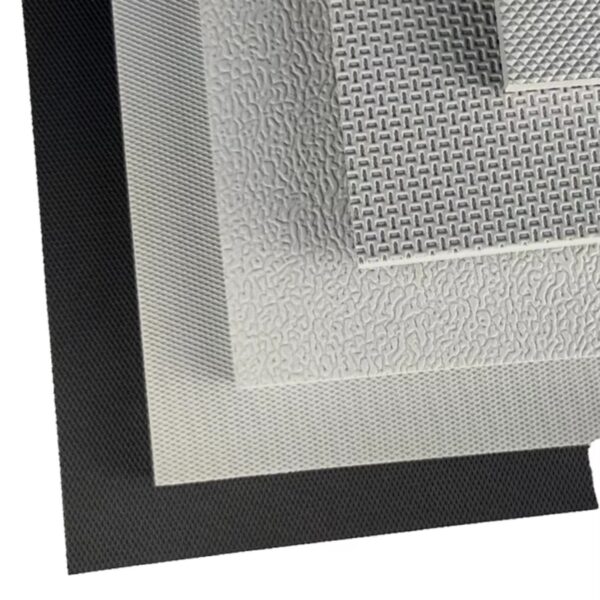

Surface Textures: Brushed, diamond, teak-style, or custom

Adhesive Option: Marine-grade PSA (e.g., 3M) available

Anti-UV: Yes

Formamide: Testing report available

Application: Boat or yacht decking and related surfaces

Origin: CN

Key Benefits

Non-slip safety: Textured surface maintains grip in wet conditions to reduce slips and falls.

Comfort underfoot: Cushions vibration and fatigue during long periods standing.

Marine durability: Resists UV, saltwater, mildew, and common marine cleaners.

Closed-cell performance: Low water absorption, easy to clean, helps with thermal and sound insulation.

Custom fit and finish: Cut, route, and bevel to templates; optional logos and multi-color inlays.

Typical Marine Applications

Main decks, cockpits, bow and stern areas

Swim platforms, transom steps, ladders

Helm pads and anti-fatigue standing mats

Hatch lids, gunwales, lockers, coolers

Trailer bunks and fender guards

Customization & Services

CAD templating and graphic design support

CNC cutting, edge beveling, logo inlays

Camouflage, solid, and dual-color options

Supplied with or without PSA backing

Kit sets packaged per boat layout

Installation Summary (PSA-backed)

Surface prep: Clean, degrease, and fully dry substrate; repair or fair uneven areas.

Dry fit: Position pieces and mark alignment.

Apply: Peel liner gradually and press from center outward to avoid air pockets.

Roll: Use a laminate roller to ensure full bond.

Cure: Avoid heavy use or washing for 24–48 hours to allow adhesive to set.

Care & Maintenance

Rinse after use with fresh water; wash with mild soap for routine cleaning.

Avoid harsh solvents, wire brushes, and high-pressure nozzles at close range.

For stubborn marks, use a soft brush with a diluted marine-safe cleaner.

Frequently Asked Questions

What is the typical lead time?

Standard sheets and rolls generally ship in about 25 days. Add 1–2 weeks for PSA backing, heat lamination, embossing, or other special processing.

Can I receive samples?

Yes. Sample kits are available in multiple thicknesses, textures, and colors/patterns.

Can the hardness be adjusted?

Yes. The EVA compound can be tuned for a softer or firmer feel, and colors can be matched to a Pantone or physical sample.

Is the foam recyclable?

EVA can be recycled where facilities exist. Production off-cuts are recycled in-house to reduce waste.

Can you produce from my CAD file?

Yes. If only minor adjustments are required, sample production typically begins within about two weeks.

Next Steps

Provide target size(s), thickness, color/texture, quantity, and whether you prefer PSA backing. A specification confirmation, sample set, or quotation will be prepared promptly.