EVA Foam Sheet Boat: Premium Quality for Marine and Automotive Applications

Enhance your marine and automotive projects with our high-quality EVA foam sheet boat solutions. Engineered for superior comfort, durability, and safety, these EVA foam sheets are ideal for a wide range of applications, ensuring optimal performance and aesthetics.

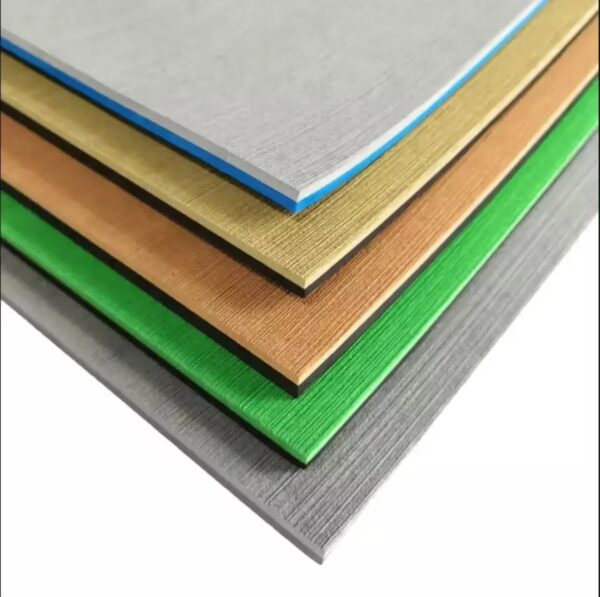

Custom Bulk Buy Brushed 6mm EVA Foam Sheet — Product Data

Product Overview

Marine- and auto-grade, closed-cell EVA sheets with a soft brushed traction face. Double-color laminated for visual contrast and easy alignment. Supplied in bulk for OEMs, installers, and distributors.

Technical Specifications

Material: EVA (closed-cell)

Density: 185 kg/m³

Standard Sheet: 2.4 m × 1.2 m × 6 mm

Thickness Options: As requested (common 5–8 mm)

Surface: Brushed, double-color lamination; “no-groove” texture (easy to clean)

Colors: Any solid or Pantone-matched; two-tone available

Origin: CN

Typical Applications: Boat flooring, RV flooring, swimming-pool surrounds, garden/yard decking; automotive mats and liners (bulk/OEM)

Key Benefits

Non-Slip Traction: Brushed top delivers reliable wet-grip underfoot.

Comfort Cushioning: Reduces fatigue and vibration when standing for long periods.

Weatherable: UV, salt, and mildew resistant for outdoor and marine use.

Waterproof & Lightweight: Closed-cell construction won’t absorb water.

Easy Fabrication: Cuts cleanly with knife/CNC; conforms to gentle curves.

Low Maintenance: Smooth, no-groove face resists trapping sand and debris.

Aesthetic Options: Two-tone and color matching for brand or interior themes.

Recommended Uses

Marine: Decks, cockpits, swim platforms, cooler lids, hatches.

Automotive: Cargo liners, trunk inserts, under-foot comfort pads.

Outdoor/Leisure: Pool edging, garden walkways, patio steps.

Commercial: Anti-fatigue standing zones, protective padding.

Customization & Services

CAD/CNC cutting to exact patterns; templating support

Routered logos, alignment marks, edge bevels, corner radii

Inlays and two-tone reveals; custom color splits

Optional marine-grade PSA (e.g., 3M) peel-and-stick backing

Palletized bulk packs for factory lines or job-site kits

Installation (PSA option)

Surface Prep: Clean, dry, and de-grease; lightly scuff glossy gelcoat.

Dry-Fit: Position and hinge-tape; verify seams and clearances.

Apply: Peel liner gradually, press from center outward to avoid bubbles.

Roll & Seal: Use a laminate roller, focusing on edges and corners.

Cure: Keep dry/low-stress for 24–48 hours before heavy use.

Care & Maintenance

Rinse after use; wash with mild soap and a soft brush.

Treat fish blood, sunscreen, and oil promptly with marine-safe cleaner.

Avoid bleach, harsh solvents, wire brushes, and close-range pressure washing.

Frequently Asked Questions

What is the lead time?

Standard sheets typically ship in about 25 days. Add 1–2 weeks for PSA backing, heat lamination, or complex CNC/kitting.

Can I get samples?

Yes. Sample kits include multiple colors, textures, and thicknesses.

Can you adjust hardness or match colors?

Yes. Hardness can be tuned via compounding; we can Pantone-match or match to your physical swatch.

Is the EVA recyclable?

EVA can be recycled where facilities exist. Manufacturing off-cuts are recycled to reduce waste.

Can you produce from my CAD file or template?

Yes. With minor revisions only, sample production can usually begin within two weeks.

Ordering Checklist

Sheet count and target yield per vessel/vehicle

Final thickness and color/two-tone scheme

PSA backing required (Yes/No)

Edge details (bevel/radius) and any routered logos

CAD/DXF/PDF files or request a paper-template guide

Ready for a bulk quote? Share the checklist details above and a tailored specification and pricing package will be prepared promptly.