Introducing our high quality EVA polygreen artificial turf padding, One of the standout features of our EVA Polygreen artificial turf padding is its superior shock absorption capabilities. This padding significantly reduces the impact on joints and muscles, making it ideal for high-traffic areas where safety is a top priority. Whether it’s a playground where children run and play or a sports field hosting rigorous activities, our EVA padding provides the necessary cushioning to minimize injuries.

High-Quality EVA Polygreen Artificial Turf Padding — Product Data

PRODUCT OVERVIEW

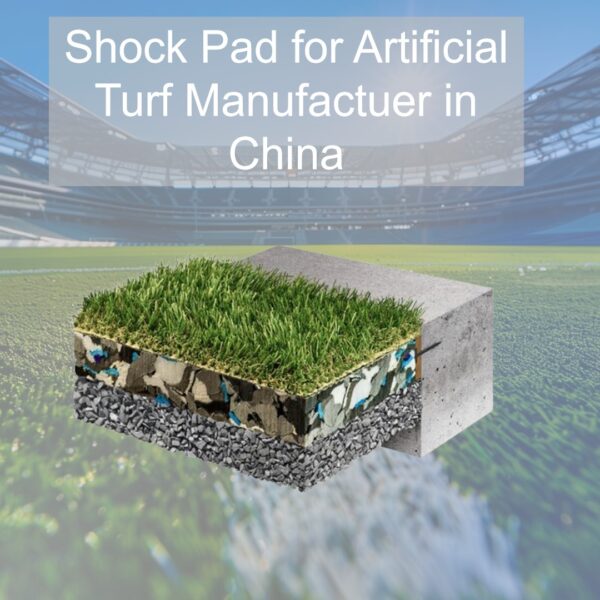

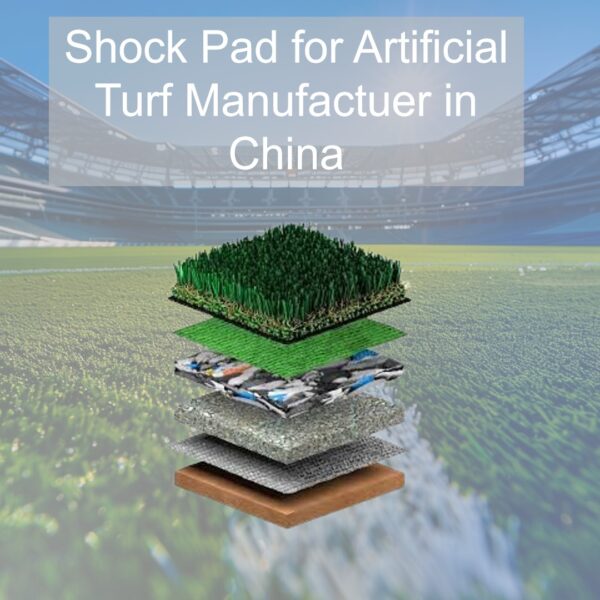

Closed-cell EVA shock-pad engineered for use beneath synthetic turf. Delivers consistent impact attenuation, player comfort, and long-term resilience for sports fields, playgrounds, and landscape installations.

TECHNICAL SPECIFICATIONS

Material: EVA (closed-cell foam)

Applications: Artificial grass underlayment, playground safety surfacing, football/soccer fields, floor mat base layers, packaging spacers

Density: Customizable to project requirements

Thickness: As specified by customer

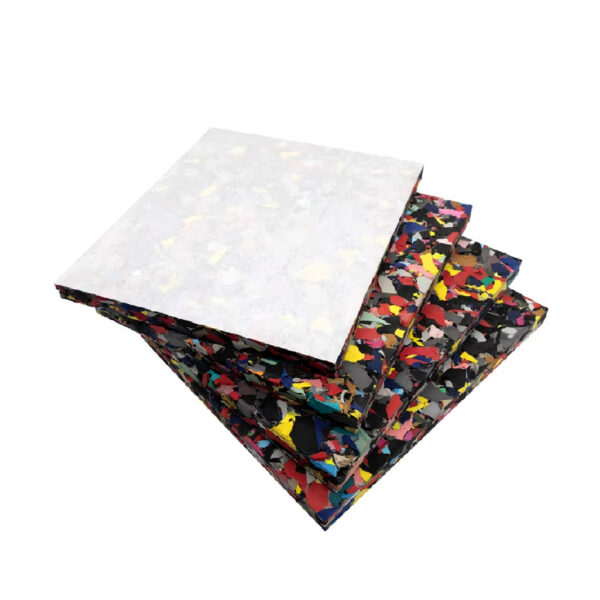

Color: Custom or Pantone-matched

Origin: CN

Feature: Turf shock pad (sheet or roll formats available)

KEY BENEFITS

Superior Shock Absorption: Helps reduce peak impact forces to protect joints and minimize injury risk.

Durable & Resilient: Maintains thickness and performance under repeated loads; resists compression set.

Weatherproof: Closed-cell structure will not absorb water; stable across temperature swings.

Quiet & Comfortable: Damps vibration, reduces field noise, and adds underfoot comfort.

Easy to Work With: Lightweight, clean-cut edges; installs quickly with common tools.

Custom-Built: Density, thickness, and color tailored to your safety targets and budget.

COMMON APPLICATIONS

Sports Fields: Football/soccer, multi-sport training areas, indoor arenas.

Playgrounds: Under synthetic turf in zones requiring impact attenuation.

Landscaping & Rooftops: Residential/commercial lawns, pet areas, terraces.

Fitness & Recreation: Multi-use zones where comfort and safety are priorities.

OPTIONS & CUSTOMIZATION

Density tuning for target impact metrics (e.g., HIC/G-max objectives)

Thickness profiles to meet site-specific fall-height or comfort goals

Perforation or drainage-channel options (project-dependent)

Sheet or roll sizes to minimize seams and waste

Adhesive choices: loose-lay with seam tape, full-bond, or perimeter-bond systems

Branding cuts or color accents (on request)

BASIC UNDER-TURF INSTALLATION

Prepare Base: Compact and level base (aggregate/asphalt/concrete as specified). Ensure drainage plan is in place.

Underlayment: Lay geotextile (if required). Unroll EVA padding, letting panels relax flat.

Seams: Butt seams snugly; tape or bond as specified in project plan. Avoid overlaps.

Turf Install: Lay synthetic turf over pad, align grain, and seam per turf manufacturer instructions.

Edges & Details: Secure perimeters and penetrations (goal posts, drains, curbs).

Infill & Grooming: Add specified infill, then brush to uniform height. Verify surface evenness and drainage.

CARE & MAINTENANCE

Keep field/turf clean of debris; follow turf maker’s cleaning schedule.

Inspect seams and high-traffic zones periodically.

Avoid prolonged exposure to harsh solvents and open flames.

Store spare padding flat and dry, away from direct UV.

FREQUENTLY ASKED QUESTIONS

Lead time

Standard rolls/sheets typically ship in ~25 days. Allow an additional 1–2 weeks for services like PSA backing, lamination, custom perforation, or kitted field sets.

Samples

Yes. Sample kits can include multiple densities, thicknesses, and finishes.

Can the pad be softer or firmer?

Absolutely. We adjust compounding and expansion to achieve your desired firmness and safety performance.

Is EVA padding recyclable?

EVA closed-cell foam can be recycled where facilities exist; we recycle production off-cuts to reduce waste.

Can you build from my CAD?

Yes. Provide your CAD/DXF and layout notes; with minor revisions, sample production can typically begin within two weeks.

ORDERING CHECKLIST

Project type (playground, sports field, landscape) and coverage area

Target performance (e.g., HIC/G-max or comfort priority)

Requested density and thickness range

Drainage needs (solid, perforated, or channeled)

Roll/sheet sizing preferences and seam plan

Bonding method (loose-lay, perimeter-bond, full-bond)

Color/branding requirements and delivery timeline

Ready for a quote? Share the checklist details, and you’ll receive a tailored specification and pricing package.