Introducing our shoe sole material rubber sheet with texture design, for footwear manufacturers committed to quality and innovation, our shoe sole material rubber sheet with texture design is an ideal choice. Combining durability, comfort, and a sleek textured finish, our rubber sheets elevate the standard of shoe soles to new heights. As a premier supplier, we ensure our products stand out in both performance and aesthetics.

Shoe Sole Material — Rubber-Feel EVA Sheet with Texture Design

(Product Data)

Rubber-feel, closed-cell EVA sheets engineered for footwear outsoles, midsoles, and heel lifts. Combines dependable grip, cushioned rebound, and cut/laminate ease for fashion, athletic, work, and hospitality footwear.

Material: EVA (closed-cell foam)

Density: Customizable (per model requirements)

Hardness: 25–80 (factory scale; tunable to your spec)

Thickness: As requested

Colors: Custom / Pantone-matched; multi-color laminations available

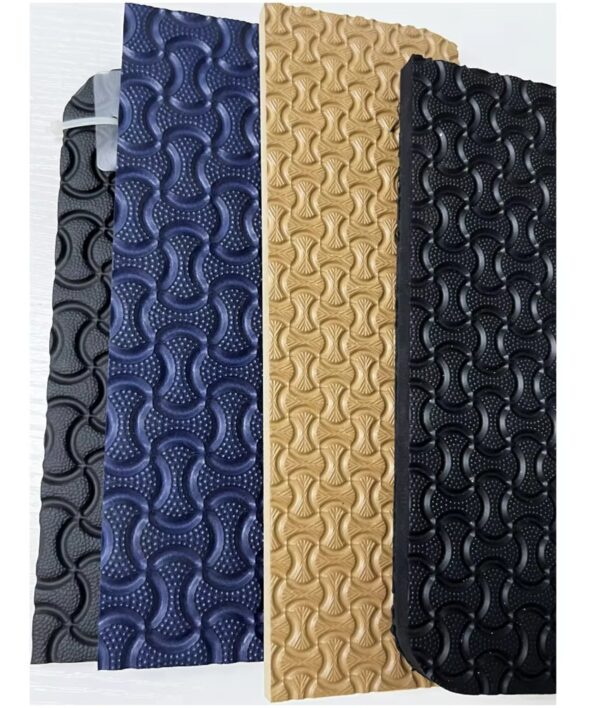

Surface: Multiple texture patterns for traction & style

Origin: CN

Feature class: Sole “rubber” sheet / outsole stock

Typical uses: Shoes, luggage components, swim boards, floor mats, packaging spacers

Durable grip: Molded/textured faces improve traction on dry/wet surfaces.

Comfort & rebound: EVA core cushions impact; supports all-day wear.

Lightweight & quiet: Cuts weight vs. rubber; low noise on hard floors.

Water & sweat resistant: Closed-cell structure resists water uptake and odor.

Process friendly: Die-cut, CNC, hot-press, and lamination ready.

Patterns: Waffle, wave, herringbone, dot, ridge, diamond, custom logos.

Constructions: Mono-layer, dual-layer color, fabric-backed, logo inlays.

Tuning: Density/durometer, abrasion mix, anti-slip blend, anti-static option.

Kitting: CAD/DXF nesting, pre-laminated stacks, size-graded kits.

Outsoles • Midsoles & wedges • Heel pads • Slippers & hotel disposables • Sandals & slides • Kids’ shoes • Orthotic bases • Non-marking indoor footwear

Cut/shape: Die-cut, kiss-cut, waterjet, or knife-CNC; round sharp corners for durability.

Forming: Heat-press emboss for texture; laminate layers under controlled temperature/pressure.

Adhesives: Compatible with standard footwear systems (e.g., PU cements, hot-melt); follow primer/open-time per adhesive supplier.

Wipe with mild soap and water; avoid harsh solvents/bleach. Inspect high-wear lugs/edges in field testing and adjust compound or texture as needed.

Lead time: About 25 days for standard sheets; add 1–2 weeks for PSA backing, heat-lamination, special textures, or kit sets.

Samples: Yes—packs with multiple densities, hardnesses, and textures.

Soft/firm options: Compound and expansion can be tuned to target feel.

Recyclability: EVA closed-cell foam can be recycled where facilities exist; in-plant offcuts are recycled.

Build from CAD: Provide CAD/DXF; with minor revisions, sample production can typically start within two weeks.

Shoe category & target feel (casual, athletic, work, hotel, etc.)

Density/Hardness range and thickness

Texture pattern and colorway(s)

Abrasion/grip targets, non-marking requirement

Sheet/kit sizes and nesting plan (CAD/DXF)

Lamination/backing needs (fabric/PSA)

Adhesive system used in your line and timeline

Share the checklist (and any CAD) to receive a tailored spec, samples, and quotation.