Cosplay Foam Manufacturer

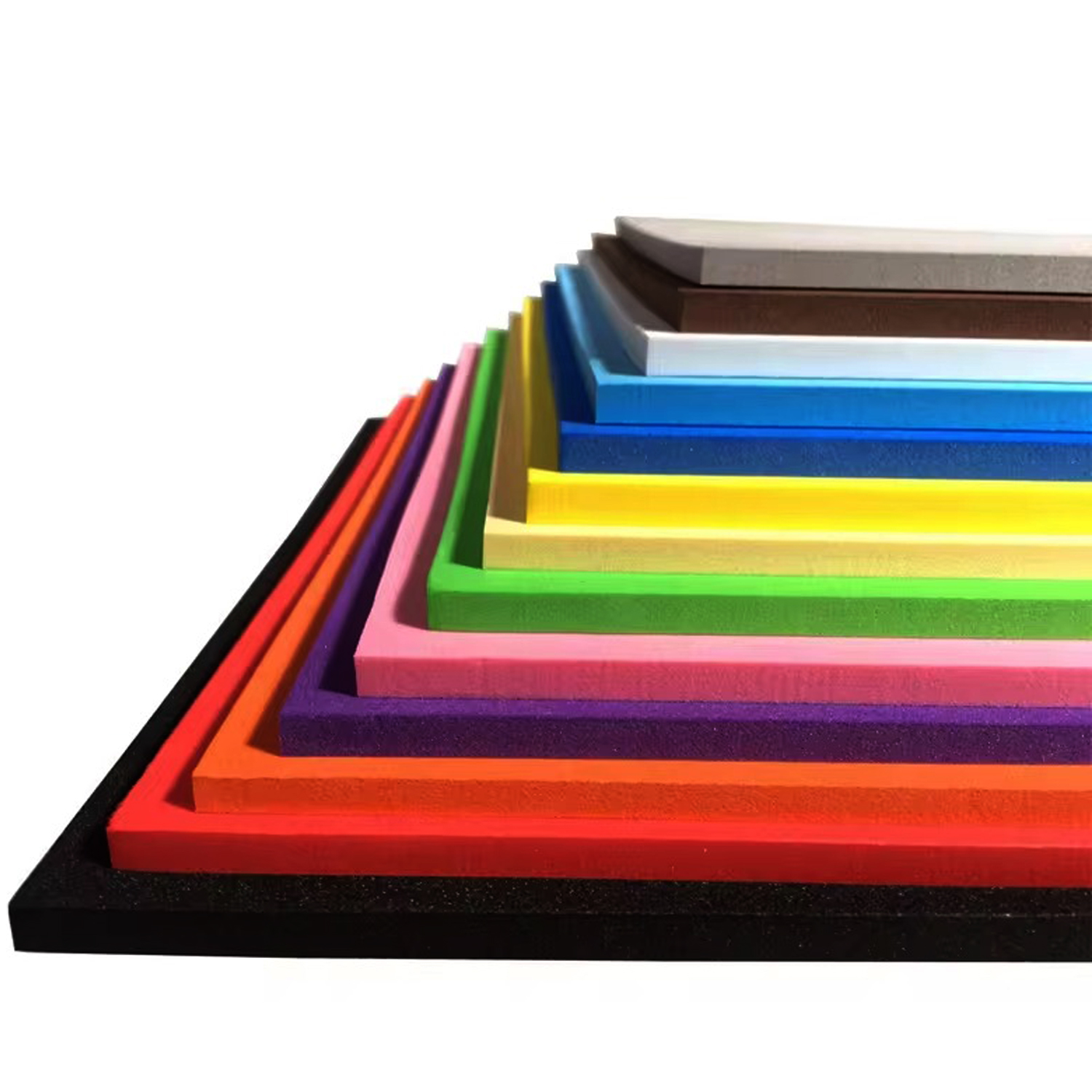

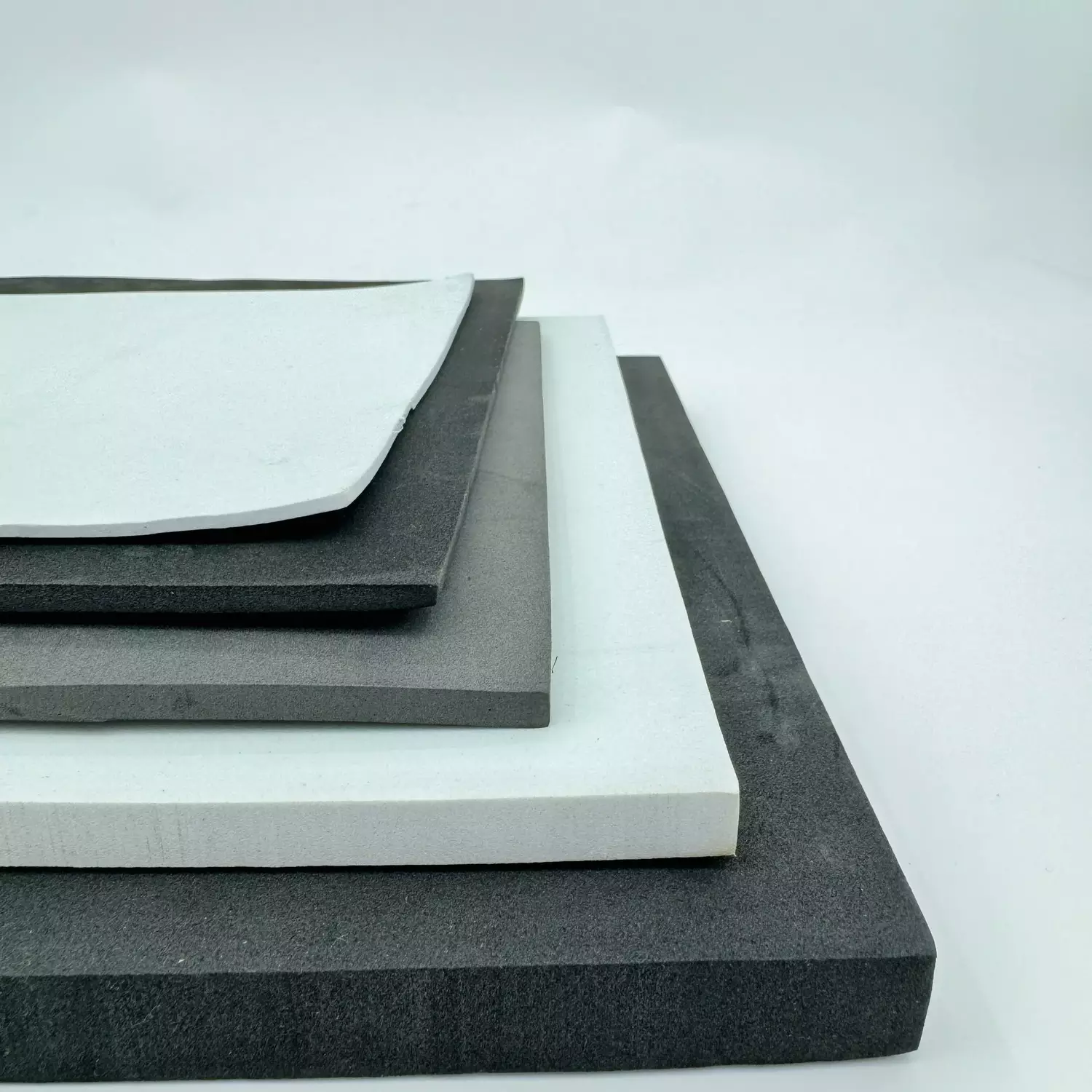

Cosplay Foam(EVA) sheets and blocks manufacturer that provide Cosplay foam sheet in a variety of colours and thicknesses.

| Material | Ethylene-Vinyl Acetate (EVA) |

|---|---|

| Uses | Costumes, props, armor, swords, futuristic robots |

| Thickness | Common options include 1mm, 2mm, 4mm, 6mm, 8mm, 10mm, etc. |

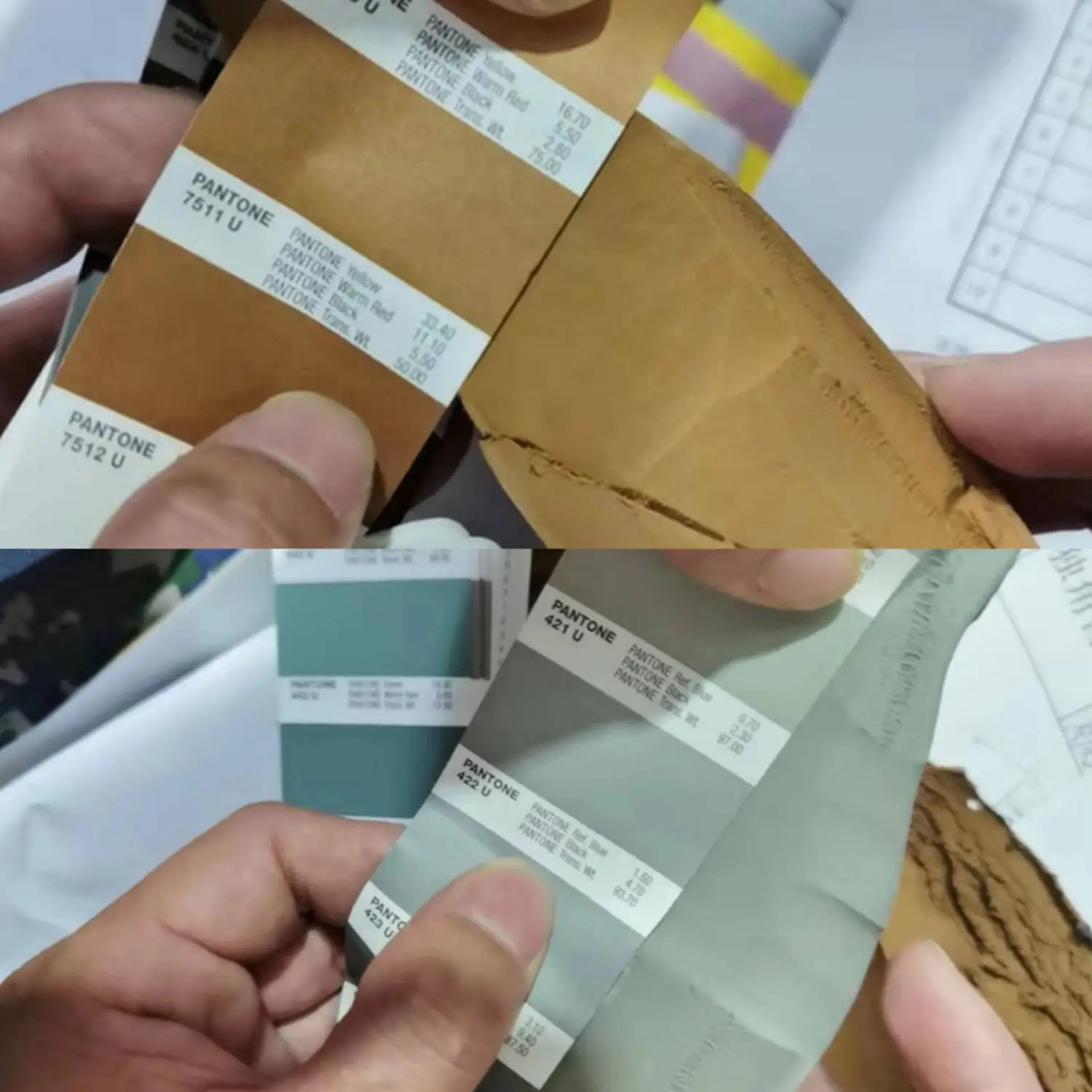

| Colors | Available in various colors (black, gray, etc.) or pantone color number |

| Density | High density for durability and detail work |

| Flexibility | Flexible and easy to cut, shape, and glue |

| Texture | Smooth surface, ideal for painting and detailing |

| Durability | Durable and resilient, maintains shape well |

| Hardness |

|

| Packing | Poly bag |

EVA foam, commonly used in cosplay, is rated for hardness on the Shore C scale. The Shore C scale measures the hardness of semi-rigid materials like EVA foam, where a higher number indicates a harder material. Here are some typical hardness values for EVA foam used in cosplay:

These hardness levels allow cosplayers to choose the appropriate foam based on the specific needs of their projects, from flexible and detailed pieces to strong and durable components.

As a EVA foam manufacuter,we are happy to introduce the production process of EVA foam.EVA foam, or ethylene-vinyl acetate foam, is a versatile material commonly used in creating costumes and props for cosplay. It is made from a blend of ethylene-vinyl acetate copolymers and additives like foaming agents and stabilizers . The blending process creates a homogeneous mixture that is then molded into various shapes and forms. EVA foam is also known for its remarkable properties, such as being lightweight, flexible, and having good gloss and clarity .. Additionally, EVA foam is also resistant to UV radiation and stress-cracking, making it a durable material that can withstand wear and tear from frequent use. When it comes to cosplay, it is commonly used to create costumes and props that require intricate designs, such as superhero costumes and sci-fi armor .

To achieve a realistic texture and appearance for EVA foam cosplay creations, cosplayers have several finishing and painting techniques at their disposal. One common method is to seal the painted foam with a clear sealer or varnish. This not only enhances the longevity of the paint but also adds an extra layer of protection against wear and tear. For cosplayers looking to add more dimension and authenticity to their foam props, weathering techniques can be used. This involves adding simulated wear and tear to the foam, such as battle damage or aging. Techniques like using a woodburning tool or heat gun to create texture, or pressing aluminum foil into the foam, can achieve these effects [4]. Different types of foam may also be better suited for specific types of cosplay. For example, EVA foam is often used for armor due to its ability to create thick edges and be molded into different shapes

Sansd, a professtional custom EVA foam manufacturer. With 43 years of foaming industry experience, we excel in providing EVA products tailored to your needs.

As an established EVA foam supplier, we offer a wide range of products, including EVA foam sheets and EVA foam rolls. Whether you require EVA foam for industrial applications or recreational purposes, such as EVA tatami mats, EVA play mats, or EVA boat decking, we have you covered.

Backed by ISO9001, ISO45001, ISO14001, GRS, and BSCI certifications, we ensure the highest quality standards. Trusted by Walmart, Aldi, Amazon seller Propad, and Disney, our strong design team and R&D department offer OEM and ODM services. Enjoy fast sampling with 1-day delivery for in-stock items. Count on our expertise to meet all your requirements

Contact Us

NEED A PROOF TO TEST QUALTIY?

Processing times typically range from 1 to 3 business days, depending on the volume of orders received. Shipping times vary based on location and chosen shipping method.Lead time takes 20 days.

Common options include 1mm, 2mm, 4mm, 6mm, 8mm, 10mm, etc.Still the thickness of cosplay form can be customized.

We offer a A4 sample for our customer to check qualtiy,free sample available.

As a cosplay foam manufacturer,we typically implement quality control processes to ensure that products meet specified standards. This involves inspections, testing, and adherence to quality assurance protocols