EVA Foam Boat Carpet Manufacturer

Custom boat carpet manufacturer that supply anti UV EVA boat flooring of different color and size include pattern like brushed surface, routered diamond,honeycomb,etc. in China.

Get Accurate Pantone Information: Obtain the exact Pantone color code from the customer. Use a Pantone color book to ensure you have the correct color reference.

Use High-Quality EVA Foam: Ensure the EVA foam you are using is of high quality and capable of accurately displaying the specified color. Different foams may absorb colors differently.

Color Matching Process: Use a color matching process that includes mixing dyes or pigments to match the Pantone color. This might involve creating test samples and making necessary adjustments to ensure a precise match.

Quality Control: Implement a quality control process to compare the final product with the Pantone color. This could include using colorimeters or visual inspections under standardized lighting conditions to ensure consistency .

Consistent Production: Maintain consistency in production by using the same batch of materials and dyes for each run. Document the process for future reference to ensure repeatability.

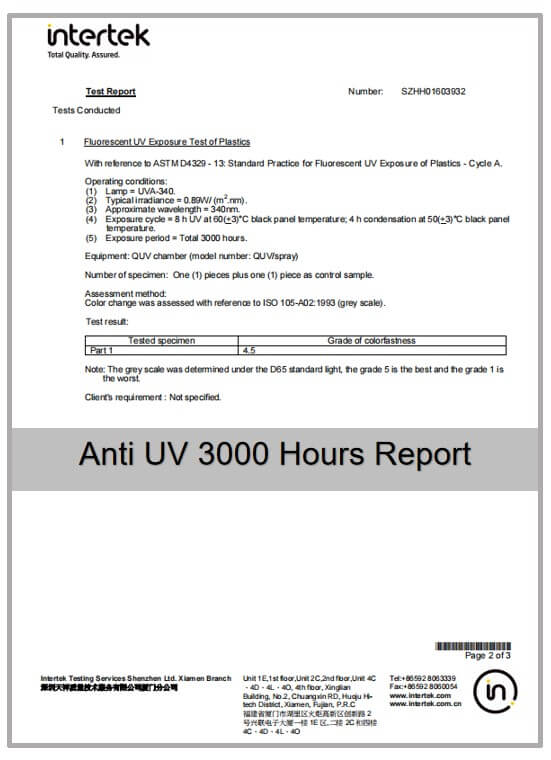

UV Degradation: EVA foam is vulnerable to UV-induced degradation, which can cause discoloration, surface degradation, and overall weakening of the material .

Longevity: Ensuring that EVA decking has effective UV protection increases its lifespan, making it more durable and reliable for outdoor use. Without UV protection, the foam can deteriorate quickly, leading to costly replacements .

Safety and Performance: Degraded EVA foam can lose its cushioning and non-slip properties, compromising safety and performance on decks. An Anti-UV 3000 report confirms that the material will maintain its essential properties over time.

Aesthetic Maintenance: UV protection helps maintain the original color and appearance of the EVA decking, ensuring it looks good even after prolonged exposure to sunlight .

Customer Satisfaction: Providing an Anti-UV 3000 report builds trust with customers by demonstrating that the product has been tested and certified for high UV resistance, ensuring they receive a high-quality, long-lasting product.

Sansd, a professtional custom EVA foam manufacturer. With 43 years of foaming industry experience, we excel in providing EVA products tailored to your needs.

As an established EVA foam supplier, we offer a wide range of products, including EVA foam sheets and EVA foam rolls. Whether you require EVA foam for industrial applications or recreational purposes, such as EVA tatami mats, EVA play mats, or EVA boat decking, we have you covered.

Backed by ISO9001, ISO45001, ISO14001, GRS, and BSCI certifications, we ensure the highest quality standards. Trusted by Walmart, Aldi, Amazon seller Propad, and Disney, our strong design team and R&D department offer OEM and ODM services. Enjoy fast sampling with 1-day delivery for in-stock items. Count on our expertise to meet all your requirements

Contact Us

NEED A PROOF TO TEST QUALTIY?

Processing times typically range from 1 to 3 business days, depending on the volume of orders received. Shipping times vary based on location and chosen shipping method.Lead time takes 20 days.If back glue needed,that will check 3M factory glue lead time.usually like 45 days lead time for EVA foam decking sheet with PSA.

Common options include 3mm, 5mm single layer,6mm laminated double layer,8mm tri layers,etc.Still the thickness of EVA car mat material can be customized.

We offer a sample for our customer to check qualtiy,free sample available.

As a foam boat flooring manufacturer,we typically implement quality control processes to ensure that products meet specified standards. This involves inspections, testing, and adherence to quality assurance protocols.And we also require the 3M factory to provide certification for every batch of PSA.