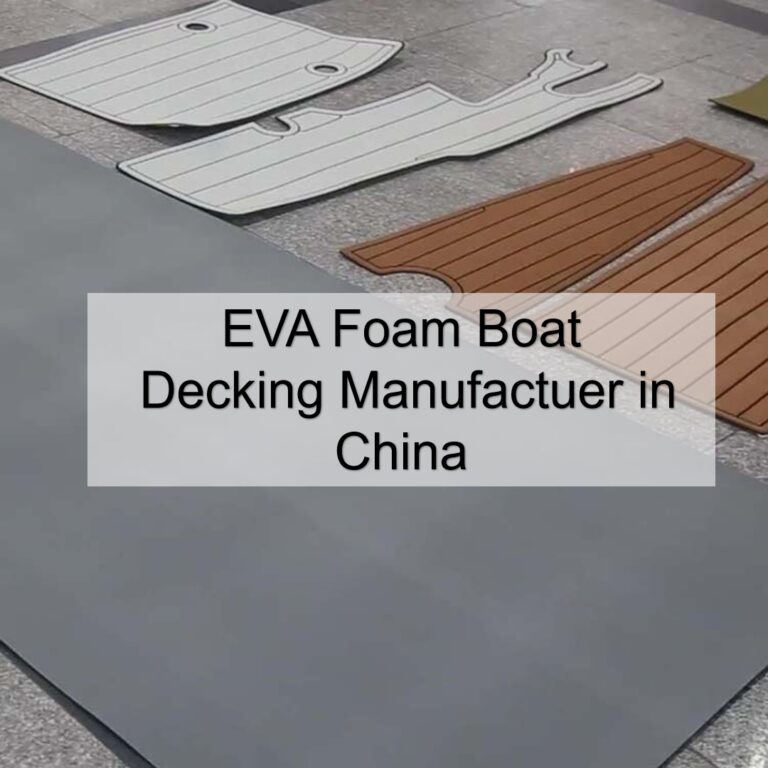

Foam Decking Sheet Manufacturer

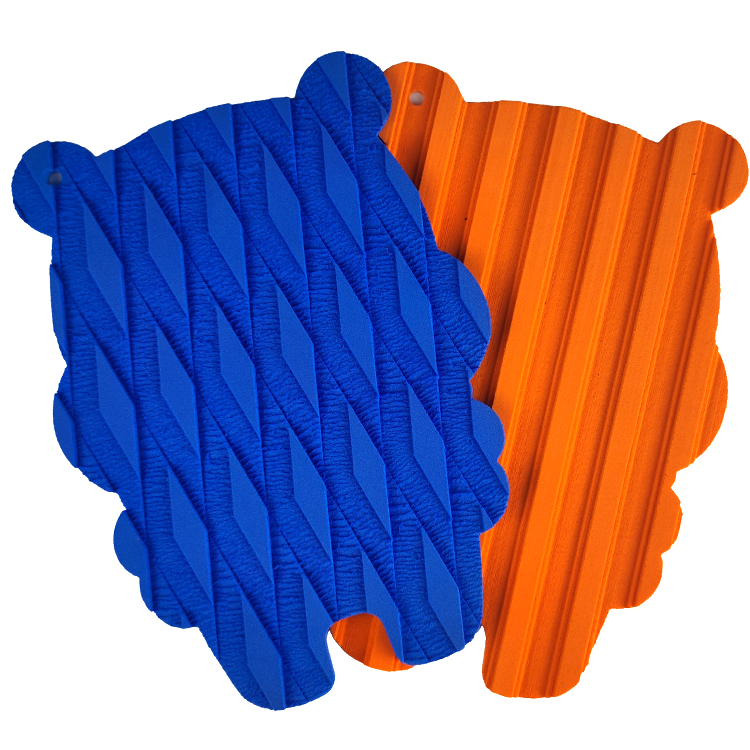

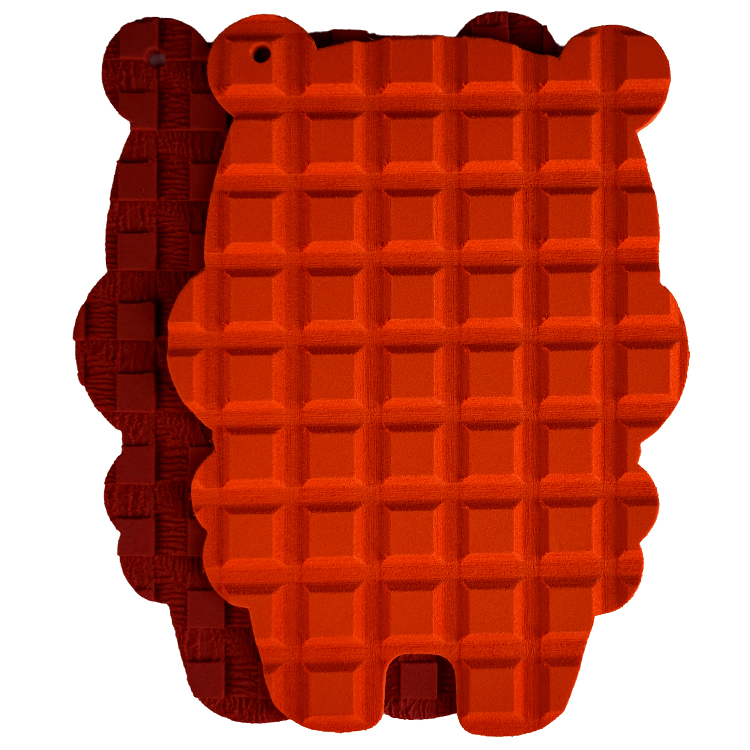

Foam decking sheet manufacturer that supply anti UV EVA boat flooring of different color and size include pattern like brushed surface, routered diamond,honeycomb,etc. in China.

| Material | EVA |

|---|---|

| Size |

|

| Thickness |

|

| Hardness |

|

| Density | 185kgs/m³ |

| Color | Teak over Black, Gray over Black, or customized |

| UV-resistant Test Standard | 3000 Hours |

| Back Adhesive | 3M Adhesive |

| Package | Wooden Pallet or Carton |

| Usage | Boat Flooring, Yacht Flooring, RV Flooring |

EVA foam, or Ethylene Vinyl Acetate foam, is a closed-cell foam material that has gained significant popularity in the boating industry, particularly for decking applications. But is EVA foam good for boats? In this article, we will explore the advantages and disadvantages of using EVA foam for boat applications, helping you make an informed decision.

Comfort: One of the most significant benefits of EVA foam is its cushioning effect. When installed as decking, it provides a soft, comfortable surface underfoot, which is particularly appreciated during long periods on the water. This padding can reduce fatigue, making your boating experience more enjoyable.

Non-Slip Surface: EVA foam naturally offers a high-traction surface, even when wet. This non-slip characteristic is crucial for safety on a boat, preventing slips and falls in wet conditions. It is especially valuable on swim platforms and other high-traffic areas.

Waterproof: Being a closed-cell foam, EVA foam is inherently waterproof. The closed-cell structure prevents water from soaking into the material, which helps in maintaining buoyancy and reducing the risk of mold and mildew growth. This makes it an excellent choice for marine environments where exposure to water is constant.

Sansd, a professtional custom EVA foam manufacturer. With 43 years of foaming industry experience, we excel in providing EVA products tailored to your needs.

As an established EVA foam supplier, we offer a wide range of products, including EVA foam sheets and EVA foam rolls. Whether you require EVA foam for industrial applications or recreational purposes, such as EVA tatami mats, EVA play mats, or EVA boat decking, we have you covered.

Backed by ISO9001, ISO45001, ISO14001, GRS, and BSCI certifications, we ensure the highest quality standards. Trusted by Walmart, Aldi, Amazon seller Propad, and Disney, our strong design team and R&D department offer OEM and ODM services. Enjoy fast sampling with 1-day delivery for in-stock items. Count on our expertise to meet all your requirements

Contact Us

NEED A PROOF TO TEST QUALTIY?

Processing times typically range from 1 to 3 business days, depending on the volume of orders received. Shipping times vary based on location and chosen shipping method.Lead time takes 20 days.If back glue needed,that will check 3M factory glue lead time.usually like 45 days lead time for EVA foam decking sheet with PSA.

Common options include 3mm, 5mm single layer,6mm laminated double layer,8mm tri layers,etc.Still the thickness of EVA car mat material can be customized.

We offer a sample for our customer to check qualtiy,free sample available.

As a foam boat flooring manufacturer,we typically implement quality control processes to ensure that products meet specified standards. This involves inspections, testing, and adherence to quality assurance protocols.And we also require the 3M factory to provide certification for every batch of PSA.