Premium EVA Material for Orthotic Milling: Perfect for the Retail and Hospitality Industry

Enhance comfort and support with our premium EVA material for orthotic milling, specifically designed for the retail and hospitality industry. This high-quality material ensures superior cushioning, durability, and performance, making it the ideal choice for creating custom orthotic solutions.

Custom EVA Material for Orthotic Milling — Product Data

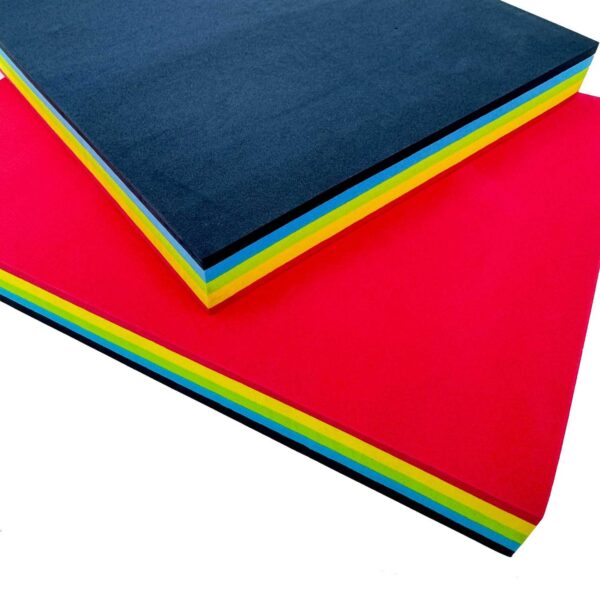

Closed-cell EVA milling blocks/sheets engineered for CAD/CAM fabrication of custom orthoses, footbeds, and accommodative inserts. Tunable density and hardness deliver the right mix of cushioning, support, and long-term resilience for retail, hospitality, clinical, and athletic use.

Material: EVA closed-cell foam (latex-free)

Applications: Orthotic milling, footbeds, heel lifts/posts, wedges, accommodative pads

Density: Customizable (typical 0.12–0.28 g/cm³)

Hardness: 25–80° Shore C (soft comfort → firm control)

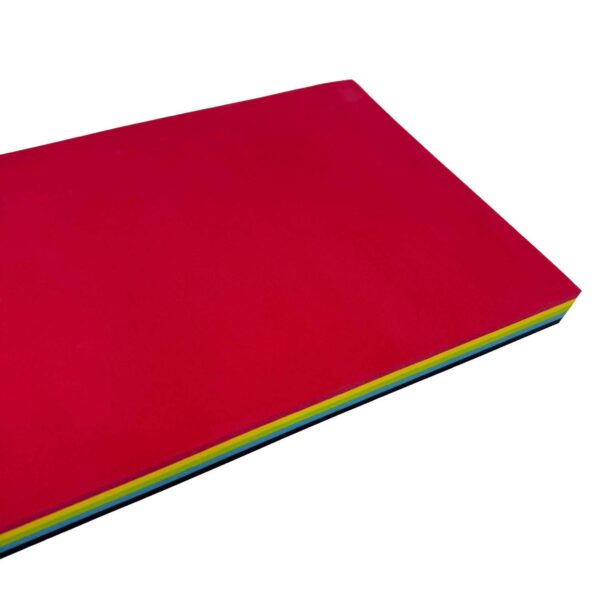

Thickness: 1–57 mm standard; thicker laminates on request

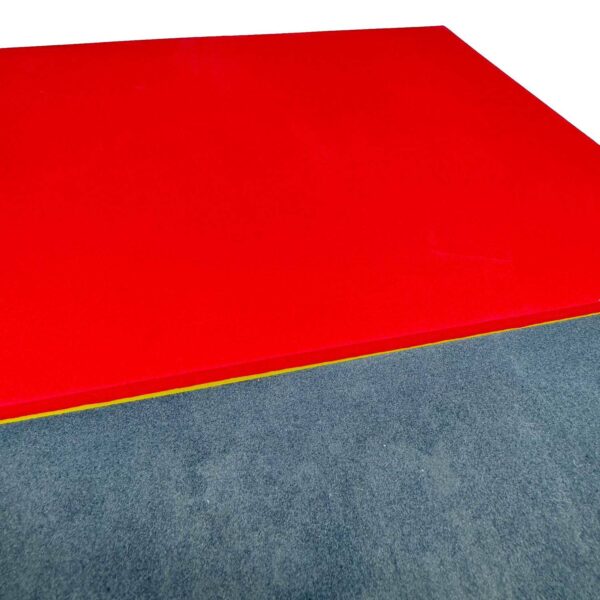

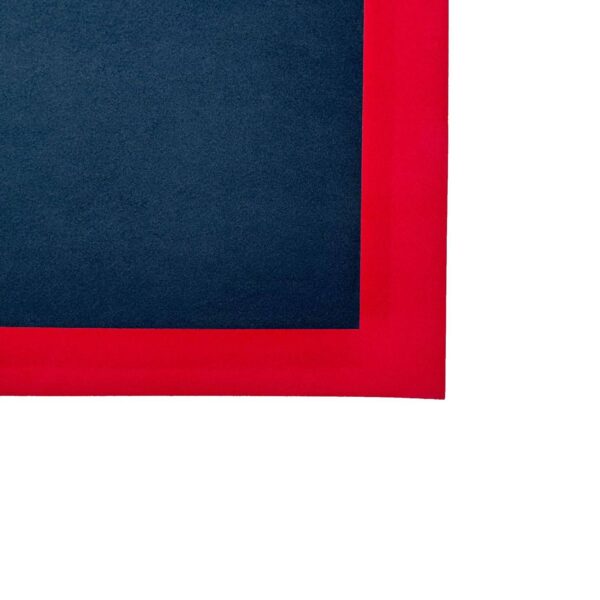

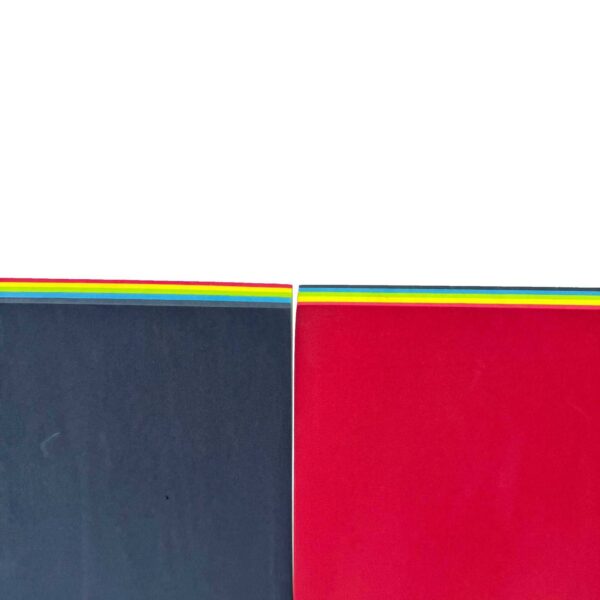

Formats: Milling blocks / sheets / billets; laminated multi-durometer stacks available

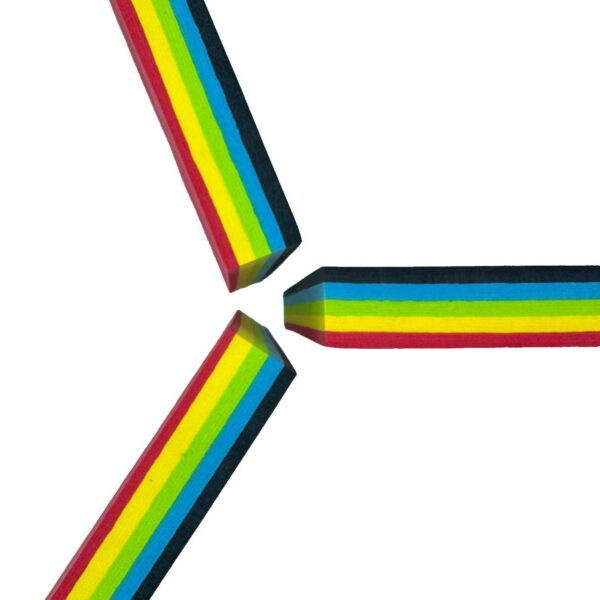

Colors: Any solid color or Pantone-matched; optional color-by-durometer system

Origin: CN

Feature: EVA orthopedic/orthotic sheet for CNC milling

Consistent machining: Fine, closed cell structure mills cleanly with crisp edges and smooth surfaces.

Comfort + control: Wide durometer range supports soft top layers with firm posting/stabilization under rearfoot/forefoot.

Lightweight & resilient: Low compression set and reliable rebound for all-day wear.

Hygienic & water-resistant: Closed cells resist moisture uptake; easy to clean and finish.

Process-ready: Bonds well to common top-covers (mesh, PU, microfiber, cork) and to EVA/rubber posting materials.

Top-cover / accommodative layers: 25–40° Shore C

General orthotic shells / footbeds: 35–55° Shore C

Posting, wedges, motion-control zones: 50–70° Shore C

High-load work/industrial inserts: 60–80° Shore C

Single, dual, or multi-durometer laminates (e.g., soft 30C surface / firm 60C base)

Pre-laminated top-covers (mesh, microfiber, antibacterial fabrics)

Pre-bonded posting sheets (EVA, EVA-rubber, cork/EVA)

Perforated or grooved comfort layers; branding deboss or printed IDs

CNC kit-packing from CAD/DXF with left/right mirrors and part labeling

Tooling: 1- or 2-flute up-cut or straight router bit, Ø 3–6 mm

Spindle speed: 8,000–18,000 rpm (use lower rpm for softer grades)

Feed rate: 1,000–3,000 mm/min (adjust to eliminate melting/fuzz)

Step-over: 40–60% of tool diameter for finishing passes

Pass depth: 3–6 mm (deeper for firmer grades)

Tips: Sharp tools, dust extraction, and light air assist improve edge quality. Avoid prolonged dwell to prevent heat marks.

Surface prep: Light sanding or scuffing; wipe with isopropyl alcohol.

Adhesives: PU/contact cements, reactive hot-melt, heat-activated films, or PSA where specified.

Lamination: Heat and press per cover supplier guidance; avoid scorching.

Edge work: Buff to radius; finish with fine grit for smooth perimeters.

Hardness: ASTM D2240 (Shore C)

Compression set: ISO 815

Abrasion/wear (for exposed bases): ISO 4649 / DIN 53516

Tensile/tear (foam): ASTM D3574 / D624 (as applicable)

Chemicals: RoHS/REACH-friendly formulations available

Store flat, dry, and out of direct UV. Keep in original wrap until use to prevent dust pickup. Clean finished devices with mild soap and water; avoid harsh solvents/bleach.

Lead time: Standard sheets/blocks ship in about 25 days. Allow +1–2 weeks for PSA, heat-lamination, multi-durometer stacks, or kit-cut sets.

Samples: Yes—sample kits cover multiple densities, hardnesses, thicknesses, and laminations.

Soft/firm tuning: Achieved by compounding/expansion; specify target Shore C and density.

Recyclability: EVA can be recycled where facilities exist; in-plant offcuts are recycled.

From CAD: Provide CAD/DXF and layout notes; after minor revisions, sample production can usually begin within two weeks.

Target device type (accommodative, semi-rigid, work/safety, sport)

Hardness and density targets for each layer/zone

Thickness(es) and laminate stack-up (single/dual/multi-durometer)

Top-cover material/color and bottom/posting requirements

Block/sheet sizes or CNC kit-packing with nesting plan

Adhesive preference (cement, heat-film, PSA)

Color/branding and labeling needs

Test/report requirements and delivery timeline

Share your CAD files and the checklist above to receive a tuned specification, machining notes, and a formal quotation.