Let’s talk plain. EVA is water-resistant, not magic. In dense sheet or closed-cell foam, it shrugs off splash, rain, and short soaks. But “waterproof” depends on structure (closed vs open), thickness, crosslinking, seams, and how you build the part. If you’re buying at scale for marine deck, orthotics, shoe parts, or car interiors, this difference matters a lot. And yes—Sansd makes this stuff every day, so we’ll keep it practical.

TL;DR: Low water uptake ≠ zero vapor ingress. For real “no-drama” waterproofing, combine closed-cell EVA + right thickness + clean lamination + sealed edges.

Small grammar warning, I know: numbers sound dry. But you need them to spec parts that don’t swell, stink, or delaminate after a season.

| Claim (what buyers say) | Data / test idea | Where it works well | Watch-outs in real builds |

|---|---|---|---|

| “EVA is waterproof.” | D570 24 h absorption ≤0.5% (dense sheet/closed-cell) | Marine deck foam, car mats, orthotic top covers, shoe midsoles, cosplay armor | Not a steel tank. Edges, seams, holes let water creep. Seal or tape them. |

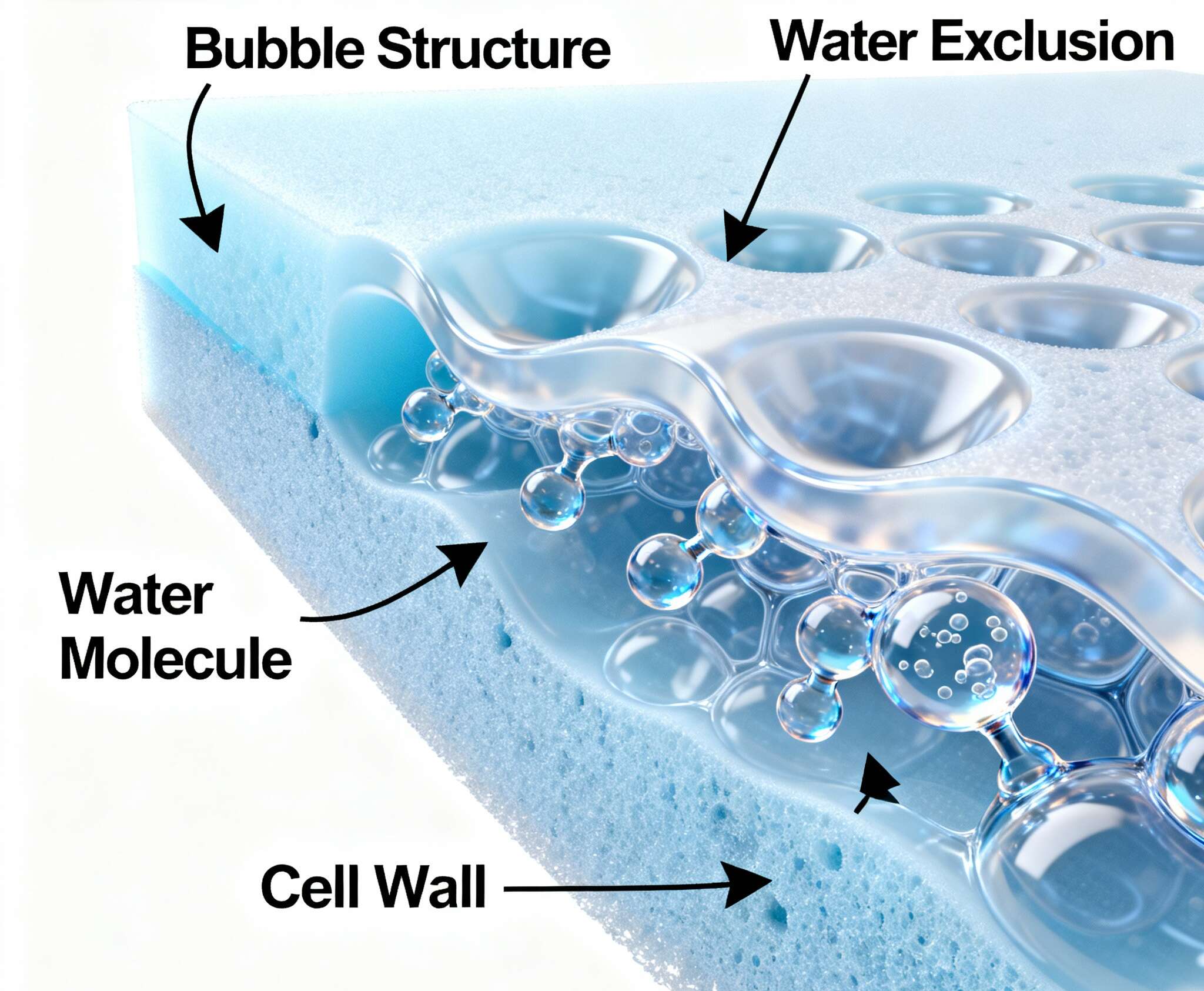

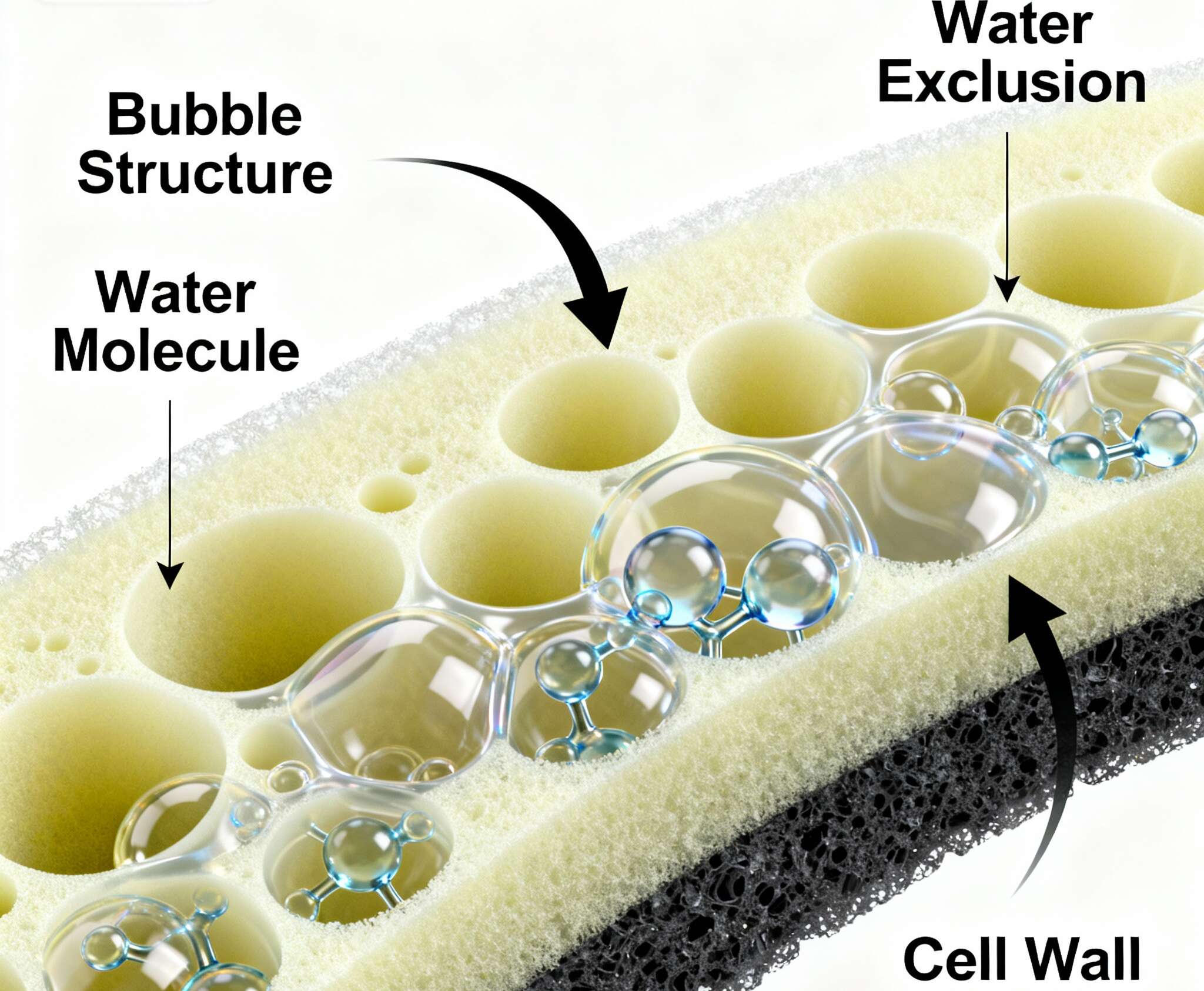

| “Closed-cell foam doesn’t soak.” | Closed cells block bulk water; minimal weight gain after soak | Boat flooring, turf padding, play mats, NVH pads | Long hot humidity → WVTR still matters; pick thicker foam or lamination. |

| “It won’t delaminate.” | Proper lamination + 3M PSA + clean surface prep | Car mat backers, insole stacks, cosplay layering | Sweat + soap + heat cycles can lift poor PSA. Ask for primers or flame-treat. |

| “Any EVA works outdoors.” | Crosslinking + UV stabilizers + thickness | Decking sheets, SUP pads, dock bumpers | Cheap blends chalk or compress long-term. Specify Shore C & density. |

Tip: when you request samples, tell the factory your target WVTR, D570 absorption, Shore C, and density. Saves two weeks of back-and-forth.

You want a deck that doesn’t drink water, drains fast, and keeps grip when wet. Closed-cell EVA shines here. With the right thickness and CNC routing, channels push water away. Big wins come from edge sealing and clean PSA lay-up—that’s where many installs fail, not the foam. If you spec with laminated textured top and mention salt-spray cycles, vendors know you mean business.

In soles and orthotics, water is mostly sweat and wash cycles. Closed-cell EVA top covers resist wet pickup, dry fast, and stay light. What kills builds? Poor bonding to PU midsoles or fabric liners. Ask for surface treatment or primer-compatible PSA. And pick Shore C carefully: too soft, you bottom out; too hard, users complain. Waterproof here = no soggy feel + no stink wicking.

Car mats see spills, rain, and steam cleaning. Closed-cell EVA doesn’t sponge up liquids, and it’s easy to water-jet or die-cut to shape. Pair EVA with grooved top and anti-skid backing; add heat-resistant PSA if you laminate. Waterproof means no soak-through, fast dry, no funk. Dont forget tolerance control on thickness; mats must sit flat.

Under-turf pads want closed-cell structure (no sponging) and perforation strategy for drainage if needed. EVA keeps weight stable after storms. Still, design for vapor: if you trap moisture under films, it creeps somewhere. Use lamination stacks that breathe where needed, or fully seal with proper edges.

Cosplayers love EVA because it shapes, heat-forms, and shrugs off sweat. Seal edges, prime before paint, and you’re good. Waterproof here means rain won’t ruin your chestplate, but please, don’t shower in it (lol). A closed-cell cosplay foam stays light and comfy.

Below is a compact spec crib to drop into your RFQ or QC sheet. Keep it simple, adjust by use case.

| Metric | Typical EVA closed-cell target | Why it matters |

|---|---|---|

| 24 h water absorption (ASTM D570) | ≤0.5% (dense/closed-cell) | Indicates low water uptake, no soggy feel |

| WVTR (23–38 °C) | low tens g/m²·day for thin films; lower with thicker closed-cell stacks | Controls humidity creep over time |

| Shore C hardness | 25–60 by scene | Softer for comfort (orthotics), harder for deck |

| Density | custom (e.g., 60–200+ kg/m³) | Weight, cushioning, cut quality |

| Crosslinking | required for outdoor | Shape hold, creep resistance |

| Surface | Emboss / brush / diamond | Wet traction, brand look |

| Backing | 3M PSA / fabric / rubber | Bonding to hulls, floors, midsoles |

Note: numbers are guidance, not holy law. Real life means tolerances, climates, and users who forget care instructions.

Closed cells block bulk water, but edges, screw holes, and seams are classic fail points. For deck kits, ask for edge-chamfer + sealant. For mats, spec wrapped edges or overlapped joints. For insoles, align grain/flow before trimming so seams sit out of sweat paths.

3M PSA on clean, dry surfaces works great; for tough substrates (gelcoat, textured plastics), request primer or flame treatment. Heat + soap + salt = harsh life. You want the right adhesive thickness and liner type for on-site install.

Thicker closed-cell stacks slow vapor and increase comfort. If your environment is hot & wet (tropics, engine bays), add thickness or barrier lam. Waterproof is a system property, not a single polymer buzzword.

You’re here for factory-direct control. Sansd runs EVA/PE closed-cell foam in sheets & rolls with Pantone color, Shore C hardness, 3M PSA, textured surfaces, and laminated stacks. We handle CNC routing, die-cutting, skiving, and logo inlay. MOQ? Talk to us. Lead time? We schedule clear. We ship COA, and materials comply RoHS/REACH. If you need boat deck foam, orthotics, car mats, cosplay, or turf padding, you get repeatable parts, not “maybe-good” parts.

If you tell the factory these up front, you wont get that awkward “oh we didn’t know” later.

EVA itself is water-resistant and low-absorption. In closed-cell form, it’s perfect for decks, mats, insoles, cosplay, and padding. But true waterproof performance comes from the whole stack—foam + thickness + lamination + edges. Get those right, and your parts stay light, clean, and drama-free through rain, sweat, and spray.

When you’re ready, ping Sansd with your scene, spec, and drawings. We’ll tune density, Shore C, thickness, color, texture, and PSA so the build fits real life, not just a datasheet.