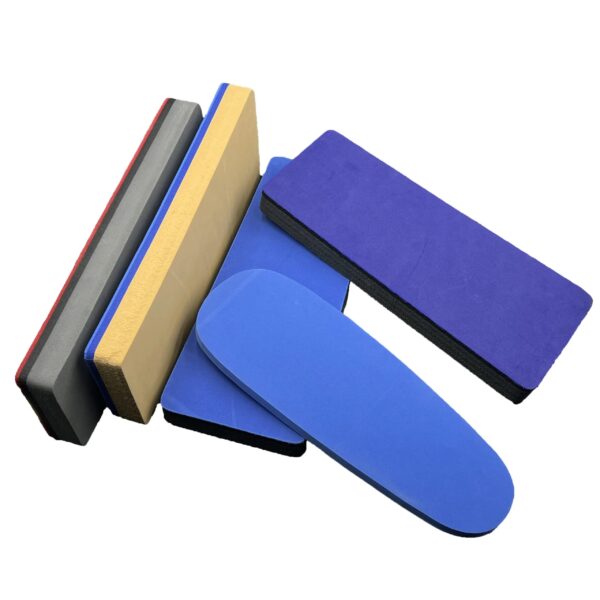

Premium EVA Orthotic Material: Optimal Support for Manufacturing and Industrial Sectors

Boost comfort and performance in the manufacturing and industrial sectors with our high-quality EVA Orthotic Material. Specifically designed to withstand the demands of rigorous environments, this material offers superior cushioning, durability, and support for custom orthotics.

EVA Orthotic Material — Product Data

Closed-cell EVA foam engineered for foot orthoses, insoles, and medical/industrial support components. Tunable comfort, stability, and grindability for labs and high-volume converters.

Material: EVA (closed-cell)

Feature options: Plain EVA or EVA–cork laminate (for natural feel and stability)

Density: Customizable to project targets

Hardness: 15–70° Shore C (soft cushioning → firm posting)

Thickness: To request (skivable; multi-layer builds available)

Color: Any custom or Pantone-matched

Origin: CN

Formats: Sheets, rolls, or CNC-cut kits

Cushioning & pressure redistribution: Resilient cell structure attenuates peak loads and hotspots.

Support tuning: Wide durometer span enables top covers, mids, bases, and posts from one system.

Thermoformable & grindable: Heat molds cleanly; feathers and finishes well on standard lab equipment.

Lightweight & closed-cell: Low water uptake; easy hygiene and quick dry.

Durability: Low compression set for long service life under repetitive gait cycles.

Durometer & density maps (soft/med/firm) for multi-duro laminates

EVA–cork, EVA–fabric, or EVA–PU film laminations

Perforated/vented top layers; embossed textures

Adhesive (PSA) backing for peel-and-stick assembly

CAD/DXF kit-packing with part IDs; left/right mirroring; batch labeling

Podiatry/orthotics: Custom FO’s, accommodative devices, postings, heel lifts, wedges

Footwear: Insoles, midsoles, comfort strobel boards

Industrial/medical: Anti-fatigue inserts, protective padding

(Also suitable for packing, toys, models, and construction uses.)

Cutting: Die-cut, CNC, waterjet; skive to thickness as needed

Forming: Heat then vacuum/pressure form; protect surfaces from scorching

Adhesives: Contact cements, reactive hot-melts, or PU—prep by light roughening and solvent wipe

Wipe with mild soap/water; avoid harsh solvents/bleach

Store flat, dry, and out of direct UV; keep wrapped to prevent dust

Lead time: Standard sheets/rolls ship in ~25 days; add 1–2 weeks for PSA, heat-lamination, perforation, or kit sets.

Samples: Yes—kits include multiple densities, thicknesses, and finishes.

Soft/firm options: Achieved by compounding/expansion to your target Shore C.

Recyclability: EVA can be recycled where facilities exist; in-plant offcuts are recycled.

From CAD: Provide CAD/DXF and layout notes—sample production can usually begin within two weeks after minor revisions.

Device type (top cover, mid, base, posting) & volumes

Target durometer(s) and thicknesses per layer

Density/weight goals and color/Pantone

Lamination stack (e.g., EVA–cork–EVA) and any PSA backing

Sheet/roll size or CNC kit-cut with nesting plan

Bonding method and finishing requirements (bevels, heel cups, wedges)

Documentation needs (RoHS/REACH) and delivery timeline

Share the checklist and we’ll return a tailored spec, stack-up recommendation, and quotation.