Introducing our high density china supplier EVA plastic material,EVA (Ethylene-Vinyl Acetate) plastic material is renowned for its exceptional flexibility, durability, and versatility, making it an ideal choice for a wide range of applications. Whether you’re in the manufacturing, construction, or consumer goods industry, our EVA plastic material offers unmatched performance and reliability.With its unparalleled flexibility, durability, and eco-friendly properties, it is the perfect solution for various applications. Partner with us and experience the quality and reliability that our EVA plastic material offers.

High-Density EVA Plastic Material — Product Data

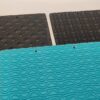

Embossed, closed-cell EVA foam sheets & rolls engineered for durable, lightweight cushioning and shaping. Tunable density and hardness make it a versatile choice for footwear, luggage, swim boards, floor mats, and protective packaging.

Material: EVA (embossed, closed-cell foam)

Density: Customizable to project targets

Hardness: 25–80° Shore C (Shore A available on request)

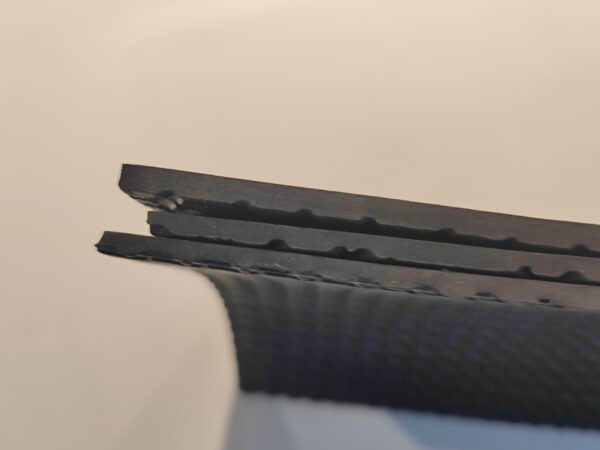

Thickness: 1–50 mm (tolerance per spec)

Color: Any custom color or Pantone-matched

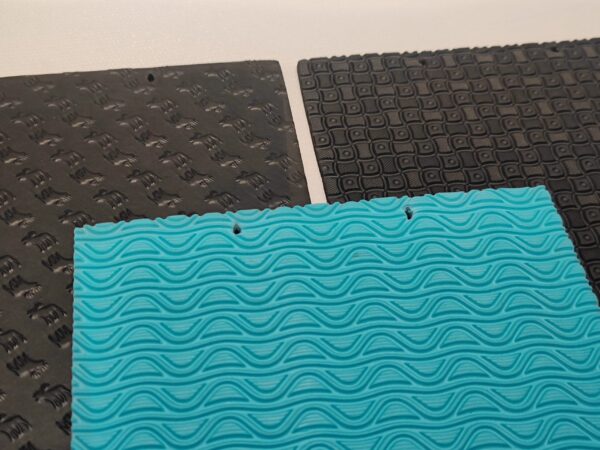

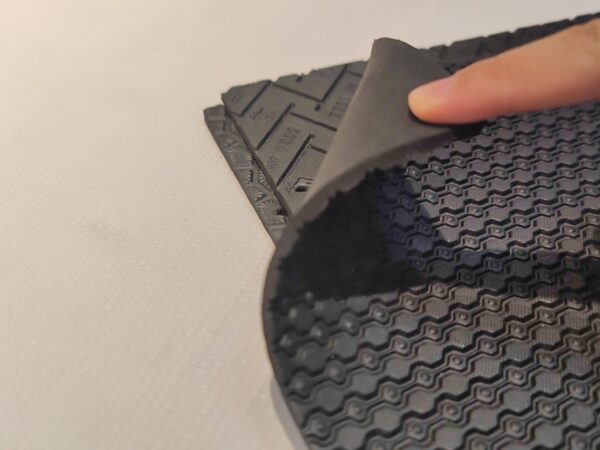

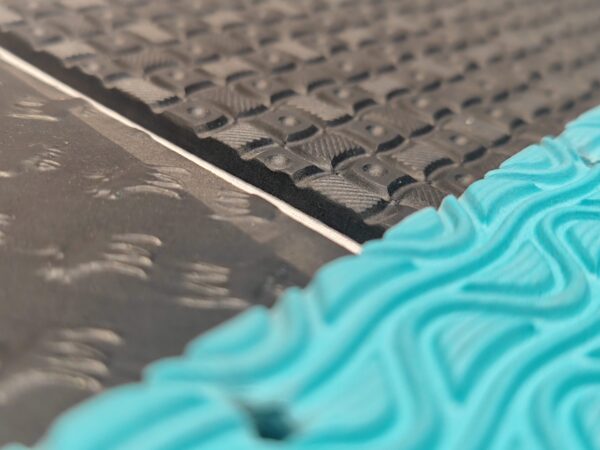

Surface: Smooth or embossed textures; multiple patterns available

Formats: Sheets or rolls; skived or molded

Origin: CN

Impact absorption & comfort: Excellent shock damping with resilient rebound.

Closed-cell performance: Water-resistant, buoyant, and easy to clean.

Lightweight & tough: High strength-to-weight for demanding daily use.

Stable feel over time: Low compression set under repeated loads.

Easy to fabricate: Cuts, routes, die-cuts, and heat-forms cleanly.

Aesthetic options: Embossed grains/patterns for grip and brand styling.

Density and hardness tuning to target cushioning/rebound

Emboss patterns (e.g., pebble, diamond, linear, custom logo)

PSA (adhesive) backing, kiss-cut parts, or full-sheet supply

Laminations: fabrics/mesh, cork, TPU films, hook-compatible toppers

UV-stabilized, anti-static, or flame-retardant grades (project-dependent)

CNC kit-packing from CAD/DXF; part numbering & branding prints

Compliance/testing documentation on request (e.g., formamide, RoHS, REACH)

Footwear: Outsoles, midsoles, sandals, slides, liners

Luggage & cases: Padding, partitions, protective inserts

Sports & swim: Kickboards, training aids, yoga/kneeling mats

Flooring & mats: Household, commercial, and anti-fatigue mats

Packaging: Shock-protective trays, end caps, and presentation kits

Cutting: Knife, die-cut, waterjet, or CNC routing

Forming: Heat-formable within recommended temp window

Bonding: Contact cements, PU adhesives, hot-melt, or factory PSA

Prep: Ensure clean, dust-free surfaces; light solvent wipe if compatible

Wipe clean with mild soap/water; avoid harsh solvents/bleach

Store flat, dry, and out of direct UV; bag for long-term storage

For sun-exposed use, specify UV-stabilized grades

Lead time: Standard sheets/rolls typically ship in ~25 days; add 1–2 weeks for PSA lamination, custom perforation/embossing, or kit sets.

Samples: Yes—sample kits in multiple densities, hardnesses, textures, and colors.

Soft/firm options: Compounding and expansion adjusted to your target feel/performance.

Recyclability: EVA closed-cell foam can be recycled where facilities exist; in-plant offcuts are recycled to minimize waste.

Build from CAD: Provide CAD/DXF and layout notes; with minor revisions, sample production can usually begin within two weeks.

End use & total coverage (m²) or part count

Target performance (cushioning, rebound, durability)

Density & hardness range and thickness

Texture/emboss pattern and color (Pantone if needed)

Lamination or PSA backing requirements

Part geometry: full sheets vs. CNC/kit-cut from CAD

Compliance/testing needs and delivery timeline

Share the checklist, and we’ll recommend the right EVA grade, texture, and build for a fast, accurate quotation.