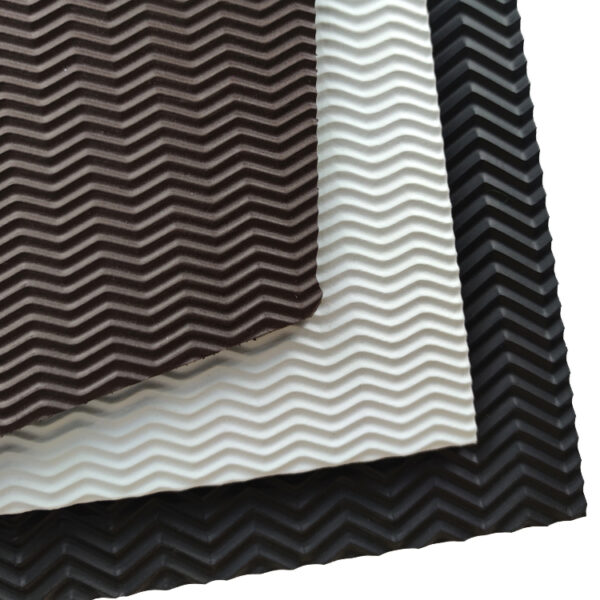

Introducing our custom wave anti slip outsole eva rubber material, the high-quality eva rubber material is the perfect solution for all your footwear needs. Crafted with meticulous attention to detail and a deep understanding of the challenges faced by individuals in various industries, this innovative outsole design offers unparalleled performance and reliability.

Custom Wave Anti-Slip Outsole EVA Rubber Material — Product Data

Closed-cell EVA outsole sheet engineered with a wave anti-slip tread for wet/dry traction, comfort cushioning, and lightweight durability. Ideal for work shoes, safety footwear, outdoor sandals, casual sneakers, and water-friendly footwear.

Material: EVA (closed-cell foam; “EVA rubber” outsole sheet)

Surface: Wave anti-slip texture (custom patterns available)

Density: Customizable to project targets

Hardness: 25–80° Shore C (soft comfort → firm, durable)

Thickness: To request (typical outsole bases 3–12 mm; midsoles/top-layers as specified)

Color: Custom/Pantone-matched (solid or two-tone)

Formats: Sheets, rolls, or molded blocks for CNC/die-cut

Origin: CN

High traction, less slip: Wave geometry creates multi-directional edges and channels water/mud away from the contact patch for confident grip.

Soft landings, lower fatigue: Resilient EVA structure provides shock absorption and energy return for all-day wear.

Durable & light: Good abrasion resistance with low density for lighter shoes and lower shipping weight.

Comfort in wet use: Closed-cell build resists water uptake; dries quickly and cleans easily.

Process-friendly: Cuts, skives, and sands cleanly; heat-formable for contouring and bonding stacks.

Indoor service / comfort clogs: 25–40° Shore C

Casual & lifestyle outsoles: 35–50° Shore C

Outdoor/hiking sandals & water shoes: 45–60° Shore C

Work/safety & high-wear zones (with rubber pads if needed): 55–80° Shore C

Custom wave pitch, groove depth, and siping per outsole CAD

Perimeter bevels, branding deboss, heel/toe traction zones

Multi-durometer laminates (soft core / firm wear layer)

Fabric scrim or PSA backing for peel-and-stick assembly

UV stabilizer package; color masterbatch to spec

CNC kit-packing from CAD/DXF (left/right mirrored, part ID labeling)

Cutting: Die-cut, waterjet, or CNC; maintain minimum web thickness to protect grooves.

Forming: Heat and press to last curves; avoid scorching with controlled platen temps.

Bonding: Roughen and solvent-wipe; use PU/contact cements or reactive hot-melt per your SOP.

Finishing: Buff edges; add rubber wear pads where extreme abrasion is expected.

Hardness: ASTM D2240 (Shore C)

Abrasion: DIN 53516 / ISO 4649

Compression set: ISO 815

Slip evaluation: SATRA TM144 or equivalent (specify surfaces/conditions)

Store flat, dry, out of direct UV. Clean with mild soap and water; avoid harsh solvents/bleach.

Lead time: Standard sheets/rolls typically ship in ~25 days; allow +1–2 weeks for PSA, lamination, perforation, or kit-cut sets.

Samples: Yes—sample kits available across densities, hardnesses, thicknesses, and tread patterns.

Soft/firm options: Achieved via compounding/expansion to your target Shore C.

Recyclability: EVA can be recycled where facilities exist; in-plant offcuts are recycled.

From CAD: Provide CAD/DXF and notes; after minor revisions, sample production can usually begin within two weeks.

Shoe category & target use (indoor, outdoor, water, work)

Target hardness and thickness per zone/layer

Tread details: wave pitch, groove depth, siping, logo/branding

Color(s) and finish (matte, two-tone, print)

Sheet/roll size or CNC kit-cut with nesting plan

Bonding method (cement/PSA) and any rubber pad co-mold/laminate needs

Test/report needs (hardness, abrasion, slip method & surfaces) and delivery timeline

Share your CAD and checklist and we’ll return a tuned stack-up, tread drawing confirmation, and quotation.