Introducing our close cell EVA foam sponge material – Versatile Applications,

Our EVA sponge material is incredibly versatile, catering to various industries and applications. In the footwear industry, it is used for midsoles, insoles, and outsoles, providing comfort and support. In sports equipment, it enhances the performance and safety of items like protective gear, yoga mats, and padding. Additionally, its use extends to toys, packaging, and even medical supplies, showcasing its adaptability and broad appeal.

Closed-Cell EVA Foam (Sponge) — Data

Specifications

Material: EVA (Ethylene-Vinyl Acetate), closed-cell

Applications: Shoes, luggage, swimming boards, floor mats, packaging, cosplay

Hardness: 25–80 (Shore C equivalent on request)

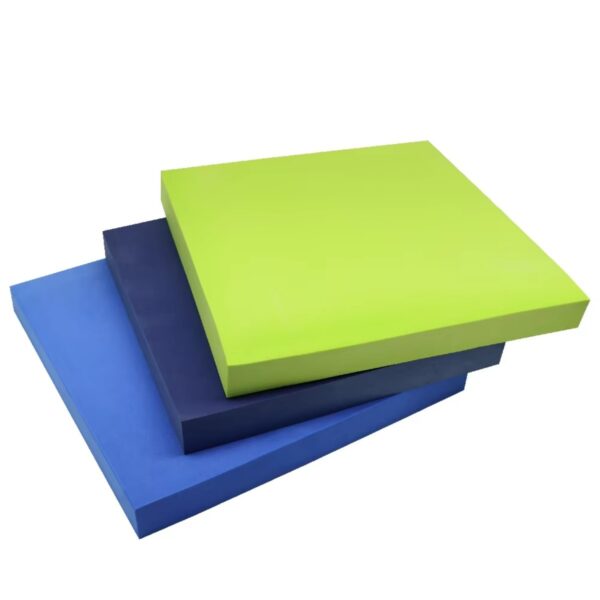

Colors: Any custom color; Pantone match available

Thickness: As requested

Surface: Multiple patterns and textures available

Origin: China

Overview

Our closed-cell EVA foam sponge delivers soft, resilient cushioning with excellent shock absorption. The closed-cell structure resists water uptake and helps the material keep its shape under repeated load—ideal for athletic, work, and everyday footwear, as well as protective packaging and durable floor mats.

Key benefits

Comfort & impact protection: Compresses smoothly and rebounds for reduced fatigue.

Durable & shape-retaining: Withstands daily wear without collapsing.

Clean aesthetics: Offered in a range of textures/patterns and custom colors.

Easy to fabricate: Suitable for cutting, skiving, thermo-forming, lamination, and PSA backing.

Applications

Footwear: Midsoles, insoles, heel cups, linings, outsoles

Luggage & cases: Padding, organizers, protective inserts

Water sports: Kickboards/swimming boards, deck padding

Facilities: Anti-fatigue and multi-purpose floor mats

Packaging: Protective inserts and case lining

Cosplay & crafts: Armor, props, and detailed costume builds

FAQ — EVA Foam Sponge Material

Q: What is the lead time?

A: Standard rolls/sheets typically ship in ~25 days. Add 1–2 weeks for PSA backing, heat lamination, or looping.

Q: Can I get samples?

A: Yes. Sample sheets/rolls are available across colors, textures, and densities.

Q: Can you adjust softness or color?

A: Yes. We can target your required hardness (within 25–80) and match colors to Pantone or your physical sample.

Q: Is EVA foam recyclable?

A: Yes. Closed-cell EVA can be recycled where facilities exist; we also recycle production offcuts.

Q: Can you produce from my CAD file?

A: Yes. Share your prototype/CAD; after minor adjustments if needed, we can start sample production.