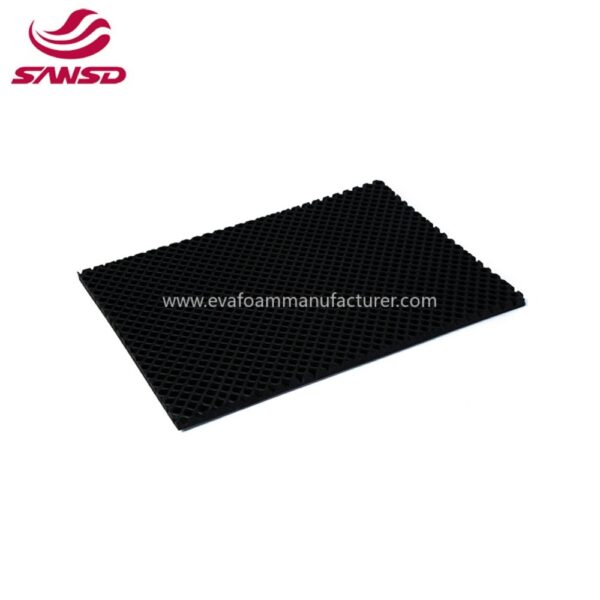

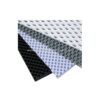

Introducing our Factory direct custom perforated EVA Car Floor Mat , EVA car floor mats are superior resistance to moisture, stains, and debris. Unlike traditional fabric or rubber mats, EVA mats are designed to be waterproof and easy to clean, making them an ideal choice for anyone who frequently transports muddy boots, wet umbrellas, or other potentially messy items in their vehicle. With a simple wipe-down using a damp cloth, you can keep your EVA mats looking like new, day after day.

Factory Direct Custom Perforated EVA Car Floor Mat — Data

Material: EVA (Ethylene-Vinyl Acetate), closed-cell

Grades: A+, A, B, C

Density: 170 kg/m³ (customizable)

Hardness: 45–60 Shore C

Roll width: 1.5 m

Thickness: 10 mm (custom options available)

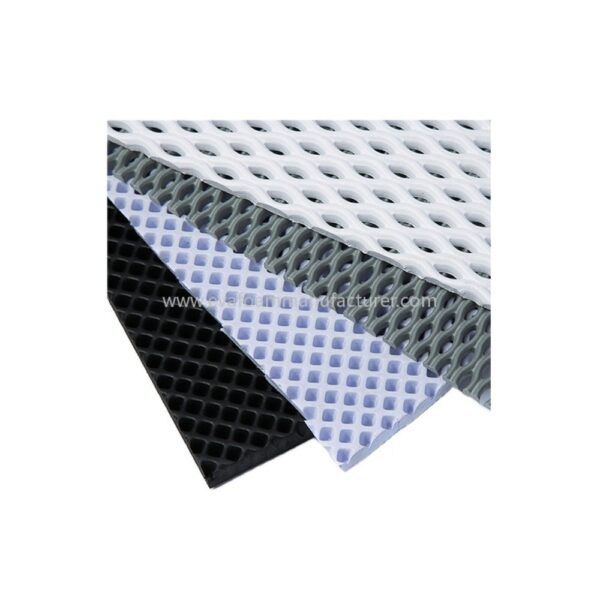

Colors: Black, Grey, Aqua Blue, White; Pantone color-match available

Origin: CN (China)

Feature highlights: perforated, anti-slip, easy to clean, odor-free, recyclable

Introducing EVA Car Floor Mat — Durable and Versatile

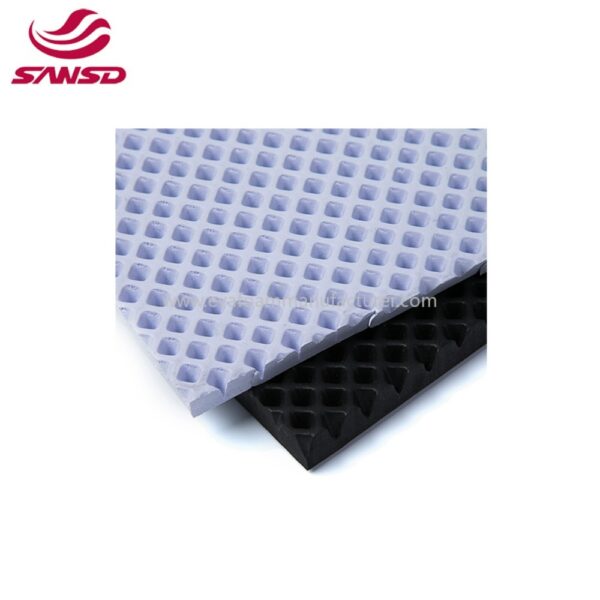

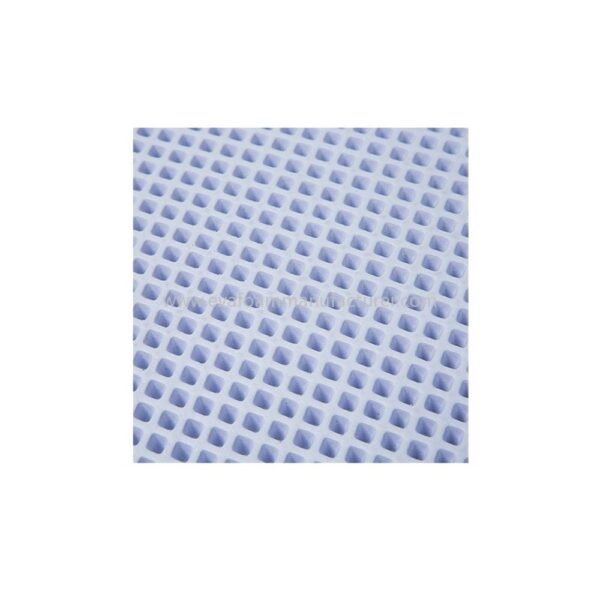

Engineered for everyday driving and rugged use, our perforated EVA mat material balances comfort, grip, and longevity. The perforation pattern channels dirt, sand, and moisture away from footwear, improving traction and simplifying cleanup. Closed-cell EVA resists water absorption, stains, and wear, while staying lightweight and flexible for easy cutting and fitting.

Why it works

Ample width & color choices: 1.5 m rolls/sheets with standard colors or Pantone-matched branding.

Real-world performance: 10 mm thickness for cushioning and sound damping without bulk.

Safer footing: textured, perforated surface enhances anti-slip performance in wet conditions.

Greener choice: non-toxic polymer; recyclable and low-odor.

Applications

Automotive: car floor mats, trunk liners, sound-damping underlays, kick-panel protection

Marine: non-slip deck inserts, locker liners

Sports & Leisure: gym floor spots, utility kneeling pads

Footwear & Accessories: insole/outsole pads, workshop anti-fatigue cutouts

Arts & Crafts: durable, easy-to-cut project sheets

FAQ — 10 mm EVA Foam Sheet

Q: What’s the lead time?

A: Standard rolls and sheets typically ship in ~25 days. Add 1–2 weeks for options such as PSA backing, heat lamination, or special looping.

Q: Can I get samples?

A: Yes—sample sheets/rolls are available in multiple densities, textures, and colors.

Q: Can you tune softness or color?

A: Absolutely. We adjust formulation/expansion to hit your target Shore C and can match colors to your Pantone or sample. Perforation patterns can also be customized.

Q: Is EVA foam recyclable?

A: Yes. Closed-cell EVA can be recycled where facilities exist. We also recycle production offcuts.

Q: Can you produce from my CAD file?

A: Yes. Provide your CAD and any notes; once minor adjustments (if needed) are confirmed, we can move straight to sample production.