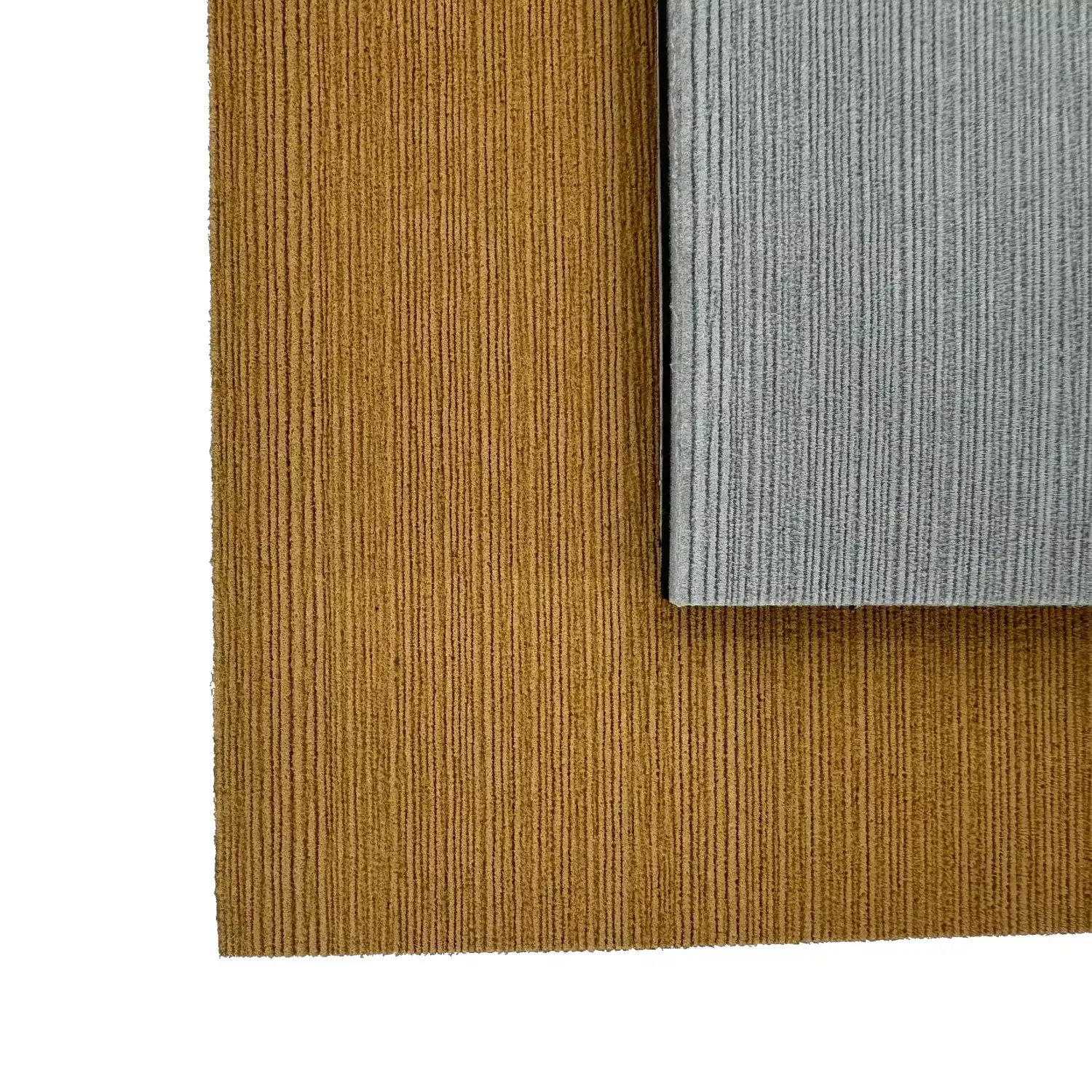

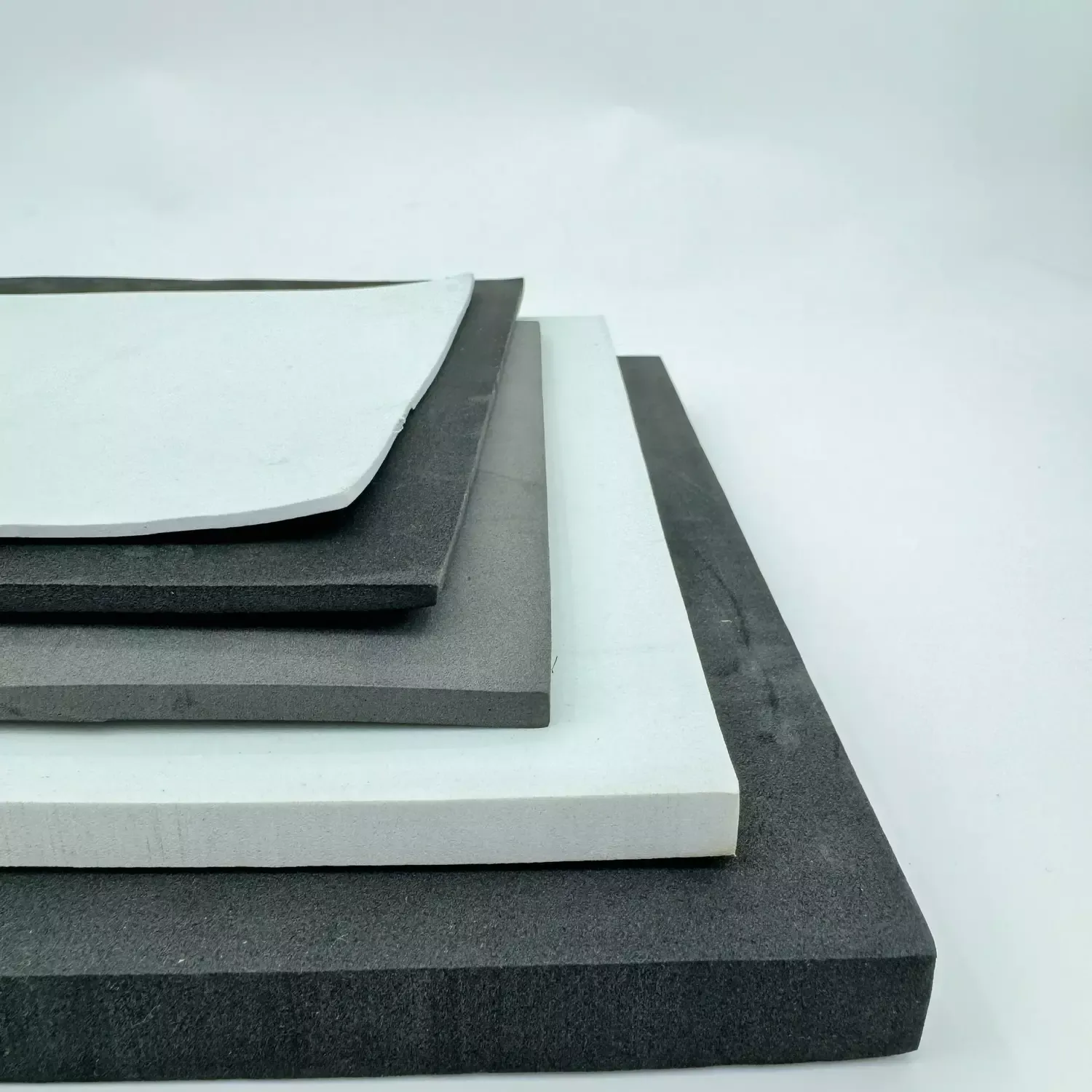

As a leading EVA foam roll supplier, we produce closed-cell EVA rolls for footwear and insoles, cosplay & crafting, flip-flops, marine/boat decking, gym & puzzle tiles, packaging, and more. Available in multiple sizes, thicknesses, colors, and finishes to match your exact spec.