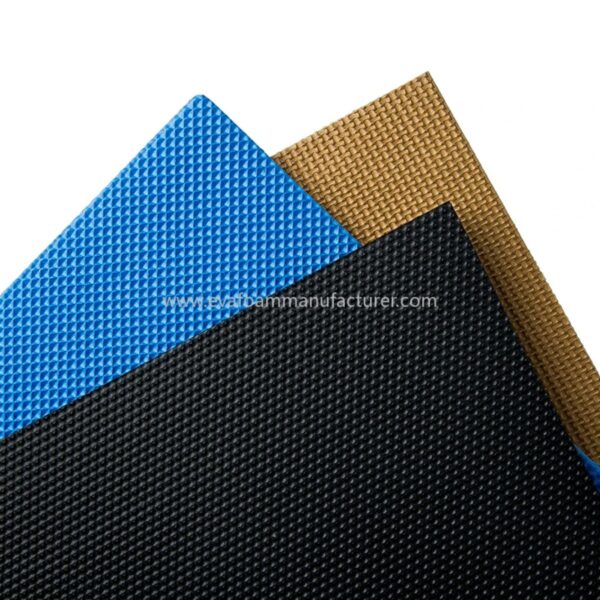

Introducing our custom embossed texture outsole material eva – Discover the perfect blend of comfort, durability, and style with our footwear featuring premium outsole material EVA. Known for its exceptional properties, EVA (Ethylene Vinyl Acetate) is a game-changer in the world of shoe manufacturing, offering unparalleled benefits that make it the ideal choice for your next pair of shoes.

High-performance EVA (Ethylene-Vinyl Acetate) outsole sheets with custom embossed traction textures. Engineered for comfort, grip, and durability across casual, athletic, beach, and safety footwear lines.

Material: Closed-cell EVA

Applications: Outsoles, midsoles, sandals/slippers bases, heel wedges, comfort inserts

Density: Customizable

Hardness: 25–80° Shore C (soft comfort → firm control)

Thickness: As specified (single or laminated)

Colors: Any solid or Pantone-matched; multi-color options available

Surface: Custom embossed textures; logo deboss/print optional

Origin: CN

Traction you can tune: Select from herringbone, wave, diamond, dot, lug, or cross-hatch textures—or provide your own pattern—for reliable wet/dry grip.

Comfort + lightweight: EVA’s micro-cell structure cushions impact while keeping overall shoe weight low.

Durable & resilient: Good abrasion resistance and low compression set for long wear life.

Water & chemical resistant: Closed-cell foam resists water uptake and is easy to clean.

Design flexibility: Cut, skive, bevel, and bond easily; works with compression molding and hot/ cold lamination.

House/slipper & beachwear: 25–35° Shore C

Lifestyle/casual: 35–45° Shore C

Athletic/training: 45–55° Shore C

Outdoor/work & posting zones: 55–70° Shore C

Heavy-duty control components: 70–80° Shore C

Textures: Any tread geometry; variable depth and pitch to target COF and flex.

Lamination: Dual/multi-durometer stacks (e.g., soft comfort layer / firm wear layer).

Backings: Fabric scrim, EVA-rubber wear layer, or PSA (pressure-sensitive adhesive).

Branding: Debossed logos, color IDs by durometer, registered tread patterns.

Sheet formats: Standard sheets, billets/blocks for CNC, pre-nested die-cut kits.

Cutting: Die-cut, waterjet, or CNC routing; keep tools sharp for crisp edges.

Molding: Suitable for compression molding; preheat per compound.

Adhesives: PU/contact cements, reactive hot-melt, or heat-activated films.

Prep: Light scuff and alcohol wipe before bonding; avoid prolonged heat dwell.

Hardness: ASTM D2240 (Shore C)

Compression set: ISO 815

Abrasion/wear (for exposed layers): ISO 4649 / DIN 53516

RoHS/REACH-friendly formulations available

Lead time: ~25 days for standard sheets; add +1–2 weeks for PSA, heat lamination, or special multi-layer builds.

Samples: Yes—texture swatches and hardness/density sets available.

Can you match my color/texture? Yes—Pantone or a physical chip; send CAD/DXF or a tread sample.

Softer or harder? We tune compound/expansion to hit a target Shore C and density.

Recyclable? EVA can be recycled where facilities exist; we recycle in-plant offcuts.

From CAD to production? Provide files and stack-up; if only minor edits are needed, sample production can typically start within two weeks.