High-Performance crosslinked PE foam:The Optimal Packaging Solution for the Electronics Industry

When crosslinked PE foam comes to safeguarding delicate electronic components, it is the industry’s top choice. Offering exceptional durability, flexibility, and superior protective properties, crosslinked polyethylene (PE) foam provides unparalleled protection for your valuable electronics.

Superior Protection for Electronics

Electronics are highly sensitive to shocks, vibrations, and static electricity. Crosslinked PE foam offers an optimal protective barrier, absorbing impacts and minimizing vibration transfer. Its closed-cell structure prevents the ingress of dust, moisture, and other contaminants, ensuring your electronic components remain in pristine condition.

Exceptional Cushioning and Shock Absorption

Crosslinked PE foam excels in cushioning and shock absorption, making it ideal for packaging fragile electronic devices. The foam’s resilience and ability to maintain its shape under pressure provide consistent protection, reducing the risk of damage during transit and handling.

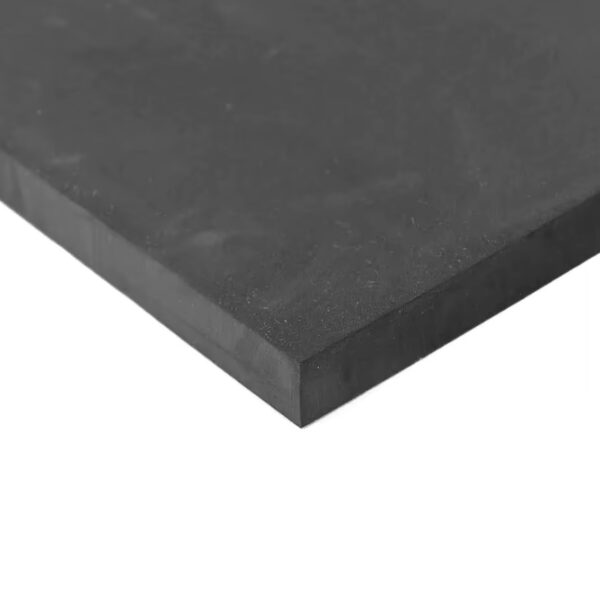

Crosslinked PE Foam Rolls & Sheets — Data

Specifications

Material: PE foam (closed-cell, crosslinked)

Features: Waterproof, non-toxic

Density: Customizable (per request)

Hardness: 25–80 (customizable)

Thickness range: 1–105 mm

Form: Rolls & sheets

Sample: Available

Origin: China

Applications: Packaging, construction, automotive, electronics

Overview

Our crosslinked PE foam provides high resilience, excellent cushioning, and a uniform fine cell structure—ideal for protecting sensitive electronics and precision parts. The closed-cell matrix blocks dust and moisture and stands up to compression, vibration, and handling.

Key benefits

Impact & vibration damping to reduce transit damage

Closed-cell barrier against dust and moisture

Resistant to many household and industrial chemicals

Lightweight, clean, and easy to fabricate (die-cutting, laminating, CNC, thermoforming)

Consistent thickness and density for repeatable protection

Optional treatments: adhesive backing, lamination, perforation, anti-static grades (on request)

Applications

Electronics: Device and component packaging, trays, cavity inserts, case lining

Automotive: NVH pads, gaskets, interior padding, wire harness protection

Construction: Floor underlay, expansion joint filler, pipe/duct insulation, sealing strips

General packaging: Corner/edge guards, protective kits, returnable dunnage

Crafts & light industry: Model making, cushioning layers, tool drawer liners

FAQ — Crosslinked PE Foam Rolls

Q: What’s the lead time?

A: Standard rolls/sheets typically ship in ~25 days. Add 1–2 weeks for value-adds like PSA backing, heat lamination, or looping.

Q: Can I get samples?

A: Yes—sample rolls/sheets are available in multiple densities and thicknesses.

Q: Can you adjust softness or color?

A: Yes. We can tune hardness within the specified range and match colors to Pantone or your physical sample.

Q: Is crosslinked PE foam recyclable?

A: Yes, where local facilities exist. We also recycle production offcuts to reduce waste.

Q: Can you build to my CAD file?

A: Yes. Share your CAD/prototype; after any minor DFM tweaks, we can begin sample production promptly.