Introducing our high density ethylene-vinyl acetate eva foam material: At the core of our EVA foam material is a carefully crafted blend of ethylene and vinyl acetate, meticulously engineered to deliver unparalleled durability, cushioning, and resilience. Unlike traditional foam materials, our high-density EVA formulation boasts a robust and sturdy structure that sets it apart from the competition.

High-Density Ethylene-Vinyl Acetate (EVA) Foam — Product Data

Closed-cell EVA foam sheets & rolls engineered for cushioning, shaping, gasketing, and lightweight structural padding. Tunable density and hardness let you dial in comfort, rebound, and durability for packaging, footwear, toys, crafts, construction models, and more.

Material: EVA, closed-cell

Density: Customizable to project targets (low/medium/high-density grades)

Hardness: 15–70 Shore C (select to tune feel & support)

Thickness: Made-to-order

Color: Any standard color or Pantone-matched

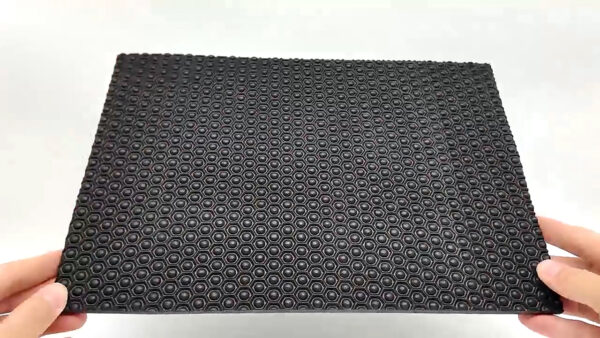

Formats: Sheets or rolls; skived or molded; smooth or textured skins

Origin: CN

Feature: General-purpose EVA foam material

Impact & shock absorption: Disperses forces for comfort and protection.

Resilient feel: Low compression set helps the foam keep its shape.

Closed-cell performance: Buoyant, water-resistant, and easy to clean.

Lightweight insulation: Thermal and acoustic damping in a low-mass form.

Easy to fabricate: Clean cutting, die-cutting, CNC, waterjet, or hand tools.

Chemical & weather resistance: Stands up to sweat, mild cleaners, and outdoor use (UV-stabilized grades available).

Density and hardness tuning for target cushioning/rebound

Surface finishes: smooth, embossed, brushed, or custom textures

PSA (adhesive) backing, kiss-cut parts, or sheet/roll supply

Laminations: fabrics, mesh, cork, TPU films, hook-compatible toppers

Color branding, part numbering, and CNC kit-packing from CAD/DXF

UV-upgrade, anti-static, or flame-retardant formulations (project-dependent)

Compliance docs on request (e.g., formamide/ROHS/REACH testing)

Packing & case inserts: Shock-protective trays, spacers, presentation kits

Footwear: Midsoles, outsoles, liners, sandals, flip-flop soles

Orthotic & health: Posting layers, arch supports, pads (per practitioner spec)

Toys & crafts: Cosplay sheets, cut shapes, DIY/decoupage

Construction & model making: Prototyping blocks, formers, expansion pads

General purpose: Floor mats, swim/kick boards, luggage padding

Cuts cleanly by die-cut, knife, waterjet, or CNC routing

Heat-formable within recommended temperature window

Bonds with contact cements, hot-melt, PU adhesives, or factory-applied PSA

Light surface prep improves adhesion (dust-free, solvent wipe if compatible)

Wipe with mild soap and water; avoid harsh solvents/bleach

Store flat, dry, and out of direct UV; bagging recommended for long storage

For outdoor/sun-exposed use, specify UV-stabilized grades

Lead time: Standard sheets/rolls typically ship in ~25 days; add 1–2 weeks for PSA lamination, perforation, or kit sets.

Samples: Yes—sample packs available in multiple densities, hardnesses, and finishes.

Soft/firm options: Compounding and expansion are adjusted to hit your target feel.

Recyclability: EVA closed-cell foam can be recycled where facilities exist; in-plant offcuts are recycled to reduce waste.

Build from CAD: Provide CAD/DXF and notes; with minor revisions, sample production can usually start within two weeks.

End use & total coverage (m²) or part count

Target feel/performance (cushioning, rebound, durability)

Density & hardness range and thickness

Color/finish and any lamination or PSA backing

Part geometry: full sheets vs. CNC/kit-cut from CAD

Compliance/testing needs and delivery timeline

Need a tailored spec or quick quote? Share the checklist and we’ll recommend an EVA grade and build the right stack-up for your application.