Premium Foam Boat Decking: EVA Material for Superior Performance

Enhance your boating experience with our premium foam boat decking, crafted from high-quality EVA material. Designed for marine environments, this decking solution offers superior comfort, durability, and safety, making it an ideal choice for any boat.

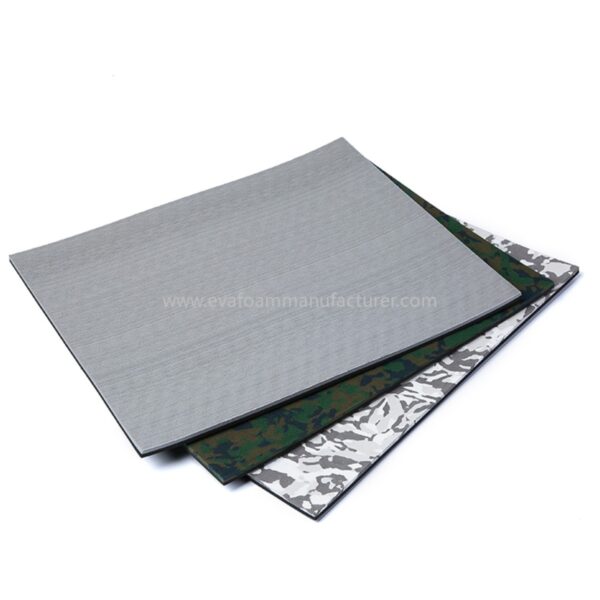

Wholesale 3M Adhesive Camouflage Foam Boat Decking — EVA Marine Material

Product Overview

Marine-grade EVA foam decking with factory-applied 3M peel-and-stick adhesive and a camouflage finish. Designed for boats and yachts that need dependable traction, comfort, and fast DIY installation.

Technical Data

Material: EVA (closed-cell)

Density: 120 kg/m³

Standard sizes: 29×29 cm, 31×31 cm, 62.5×62.5 cm, 1×1 m (custom sizes available)

Thickness: As requested (common: 3 / 5 / 6 / 8 mm)

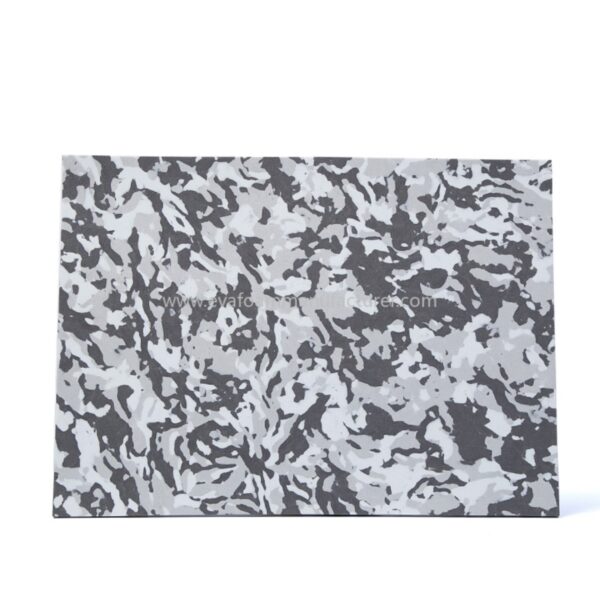

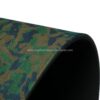

Colors/Pattern: Camouflage; solid and dual-color options; Pantone matching available

Anti-UV: Yes

Formamide: Testing report available

Application: Boat/yacht decking, steps, platforms, hatches

Project support: Graphic design/CAD templating

Origin: CN

Key Benefits

Secure footing: Textured, non-slip surface maintains grip in wet conditions.

Comfort underfoot: Cushions vibration and reduces fatigue on long days afloat.

Weather resistance: UV, saltwater, and mildew resistant to retain appearance.

Quick install: 3M adhesive backing for clean, tool-light installation.

Easy care: Rinses clean; mild soap removes most stains and scuffs.

Custom look: Camouflage aesthetic with optional logos, routes, and bevels.

Typical Marine Applications

Main decks, cockpits, bow and stern areas

Swim platforms and transom steps

Helm pads and standing mats

Hatch lids, coolers, lockers, gunwales

Trailer bunks and fender guards

Options & Services

Custom kit sets to your templates (digital or paper)

Pattern choices (brushed, diamond, teak-style)

Logo inlays, edge beveling, CNC routing

With or without 3M PSA backing

CAD/graphic design assistance for complex layouts

Installation Summary

Clean and degrease the substrate; dry completely.

Dry-fit all pieces and mark alignment.

Peel the liner gradually; apply firm, even pressure from center outward.

Roll the surface to maximize bond; allow adhesive to cure before heavy use.

Care & Maintenance

Rinse with fresh water after use; wash with mild soap for spills.

Avoid harsh solvents, high-pressure nozzles at close range, and abrasive brushes.

For stubborn marks, use a soft brush with a diluted marine cleaner.

Frequently Asked Questions

What is the typical lead time?

• Standard sheets and rolls usually ship in about 25 days. Add 1–2 weeks for PSA backing, heat lamination, embossing, or special processing.

Can I get samples?

• Yes. Sample packs are available in multiple thicknesses, textures, and colors/patterns.

Can the hardness be adjusted?

• Yes. We can tune the compound for a softer or firmer feel and match colors to a Pantone or physical sample.

Is the foam recyclable?

• EVA can be recycled where facilities exist. We recycle in-process off-cuts to reduce waste.

Can you produce from my CAD file?

• Yes. If only minor adjustments are needed, a sample is typically produced in about two weeks.

Next Steps

Share your target size(s), thickness, camouflage style, quantity, and whether you want 3M PSA backing. We’ll recommend the most cost-effective spec, send samples, or provide a fast quotation.