Our high density playground turf padding provides a cushioned surface that significantly reduces the risk of injuries. Whether it’s a playground, sports field, or recreational area, the enhanced shock absorption properties of this padding offer unparalleled protection. Parents and caregivers can have peace of mind knowing that their children are playing on a safe surface.

High-Density Playground Turf Padding — Product Data

PRODUCT OVERVIEW

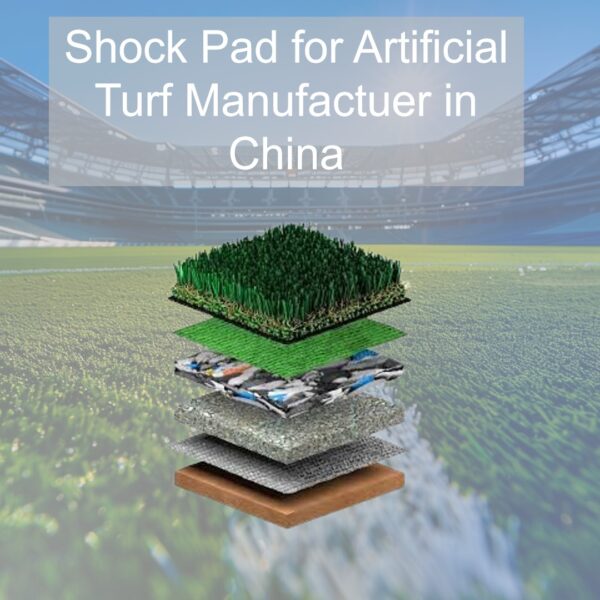

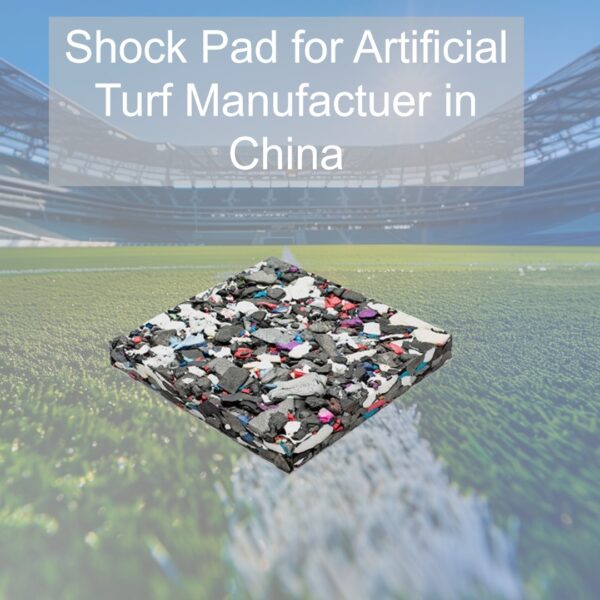

Closed-cell EVA underlayment engineered for high-traffic play zones over concrete, asphalt, or compacted aggregate. Delivers consistent impact attenuation, surface stability, and acoustic damping for schools, parks, and commercial play spaces.

TECHNICAL SPECIFICATIONS

Material: EVA (closed-cell foam)

Feature: Playground turf padding / shock layer

Applications: Artificial turf systems, playground padding, football/soccer training zones, floor-mat base, packaging spacers

Density: High-density formulation (customizable to project targets)

Thickness: As per customer request

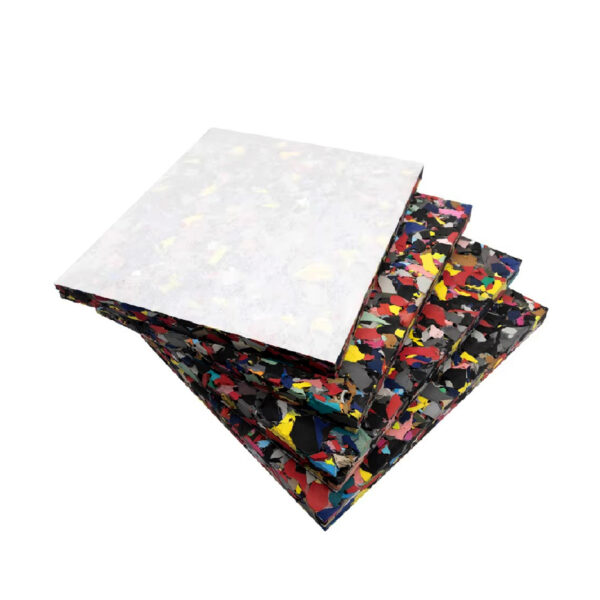

Color: Customized or Pantone-matched

Origin: CN

KEY BENEFITS

Safety & Impact Control: Helps reduce peak forces (HIC/G-max tuning available) for safer falls and comfortable play.

Built for High Traffic: High-density core resists deformation and rutting; low compression set over repeated loads.

Weather & Water Resistant: Closed-cell structure resists water uptake; optional perforation/channels support drainage.

Stable Over Hard Bases: Adds resilience, thermal break, and sound reduction over concrete/asphalt.

Fast, Clean Install: Lightweight sheets/rolls cut precisely; simple seaming speeds installation.

Cost-Effective Lifecycle: Durable construction lowers maintenance and replacement frequency.

TYPICAL APPLICATIONS

Playgrounds: Under-turf safety layer in fall-attenuation zones (swings, slides, climbers)

Sports: Small-sided football/soccer, multi-sport training areas, indoor courts

Education & Municipal: Schools, childcare centers, community parks

Residential & Rooftop: Backyards, pet areas, terraces, balcony greens

OPTIONS & CUSTOMIZATION

Density tuning to meet target comfort/HIC/G-max objectives

Thickness selection to match fall-height goals

Solid, perforated, or channeled versions for drainage strategy

Roll/sheet sizing to minimize seams and waste

Bonding method: loose-lay with seam tape, perimeter-bond, or full-bond (project dependent)

PSA backing, color accents, CNC shaping, and kit-packing from CAD/DXF

INSTALLATION GUIDE (OVER CONCRETE/ASPHALT)

Surface Prep: Clean, dry, and level substrate; repair cracks/spalls; verify slope/drainage.

Moisture/Vapor: Install a compatible barrier if required by the turf design.

Layout: Unroll padding, allow to relax; cut around penetrations/edges; butt seams (no overlap).

Seaming: Tape or bond seams per spec to create a smooth, continuous plane.

Turf Install: Place turf and seam per manufacturer instructions; secure perimeters.

Infill & Finish: Add specified infill, brush to height; confirm evenness and drainage.

CARE & MAINTENANCE

Follow the turf system’s cleaning plan; keep the surface free of debris.

Inspect seams/edges and high-traffic zones periodically; repair as needed.

Store spare material flat, dry, and out of direct UV.

FREQUENTLY ASKED QUESTIONS

Lead Time: Standard rolls/sheets ship in ~25 days; add 1–2 weeks for PSA backing, heat-lamination, perforation, or kit sets.

Samples: Yes—kits available with multiple densities, thicknesses, and finishes.

Soft/Firm Options: Compounding/expansion adjusted to your preferred feel and safety performance.

Recyclability: EVA closed-cell foam is recyclable where facilities exist; production offcuts are recycled in-plant.

Build from CAD: Yes—provide CAD/DXF; with minor revisions, sample production can typically begin within two weeks.

ORDERING CHECKLIST

Project type and total coverage (m²)

Target performance (comfort, HIC/G-max, fall height)

Desired density and thickness range

Drainage approach (solid, perforated, or channeled)

Roll/sheet sizing and seam layout

Bonding method (loose-lay, perimeter-bond, full-bond)

Color/branding needs and timeline

Share the checklist to receive a tailored specification and quotation.