Introducing our customized textured EVA foam sheets for outsole, Discover the perfect blend of durability, comfort, and customization with our premium textured EVA foam sheets for outsole applications. Designed with meticulous attention to detail, these foam sheets are ideal for creating high-quality outsoles that enhance the performance and comfort of your footwear.

Customized Textured EVA Foam Sheets for Outsoles — Product Data

PRODUCT OVERVIEW

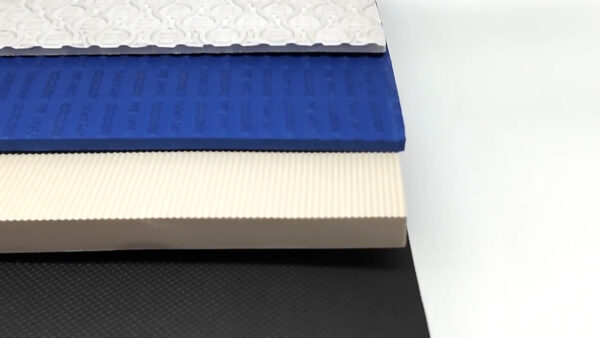

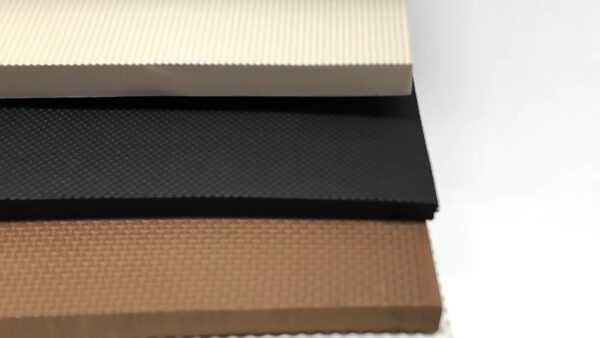

Closed-cell EVA outsole stock engineered for cushioning, traction, and long wear. Supplied as textured sheets ready for die-cutting or CNC, with compound, color, and pattern customized for sport, casual, sandal, slipper, and safety footwear programs.

TECHNICAL SPECIFICATIONS

Material: EVA (closed-cell foam) outsole sheet

Applications: Outsoles, midsoles, heel pads, sandals/slippers, luggage parts, mats, protective padding

Density: Customizable (typical outsole range 0.18–0.30 g/cm³)

Hardness: 25–80 Shore (A/C per project requirement)

Thickness: Per request (common 2–15 mm; multilayer builds available)

Sheet Size: Standard and custom cut plans to minimize waste

Colors: Solid, two-tone, or Pantone-matched; marble/speckle options

Origin: CN

Feature: “Sole rubber sheet” format for in-house cutting or pre-laminated kits

KEY PERFORMANCE BENEFITS

Cushioning & Energy Return: Tunable resilience for sport or comfort lines.

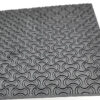

Traction: Molded surface textures deliver dry/wet grip; CoF can be pattern-tuned.

Abrasion Resistance: Durable EVA compounds for extended outsole life.

Flex & Cold Performance: Optional cold-flex formulations for low-temp use.

Lightweight: Significant weight savings versus rubber blends.

Water & UV Resistance: Closed-cell construction resists water uptake; UV-stable colors on request.

Consistent Quality: Low compression set and stable hardness across batches.

TEXTURES & FINISHES (examples)

Herringbone • Ripple • Diamond • Hex/Honeycomb • Golf-ball • Wave/Siped • Dot/Micro-dot • Brushed • Pebble • Custom logo emboss/deboss.

Edges: square, beveled, or skived. Anti-marking compounds available for indoor floors.

OPTIONS & CUSTOMIZATION

Compound: Soft comfort to firm utility; anti-slip/wet-grip; anti-static options.

Constructions: Single layer, dual-density EVA, EVA+cork, EVA+rubber blend top-sheet, color-laminated stripes.

Sustainability: Recycled EVA content on request; in-plant regrind options.

Compliance: Material selections aligned to REACH/Prop 65 upon request.

Branding: In-sheet color stripes, embossed logos, print or transfer on exposed areas.

Packaging: Bulk or size-sorted packs; barcode/lot marking.

PROCESSING GUIDE (factory)

Cutting: Steel-rule die, CNC, or water-jet; keep blades sharp to prevent burring.

Thermoforming/Hot Press: Light heat/pressure can set curvature or bond layers; validate temperature/time by compound.

Lamination: EVA-to-EVA or EVA-to-textile with hot-melt films, flame, or adhesive press; priming as required.

Adhesion to Uppers/Midsoles: Use EVA-compatible contact cements or PUR; roughen bonding face; follow adhesive supplier specs.

Finishing: Edge skiving, buffing, and brushing for traction feel and aesthetic.

QUALITY & TEST SUPPORT

DIN abrasion targets, wet/dry slip on chosen pattern, flex/bend, hardness, density, and compression set—tested to your spec plan. Formamide/VOC reports available.

CARE & STORAGE

Store flat, dry, out of direct UV/heat. Allow sheets to acclimate to cutting room conditions for best yield. Clean with mild soap/water; avoid solvents on finished colors.

FREQUENTLY ASKED QUESTIONS

Lead Time: Standard sheets ~25 days; add 1–2 weeks for special lamination, printing, PSA backings, or kit-cut sets.

Samples: Yes—texture decks and compound/hardness swatches are available.

Soft/Firm Options: Compounding and expansion are tuned to your hardness and feel.

Recyclability: EVA closed-cell foam is recyclable where facilities exist; production offcuts are recycled in-plant.

Build from CAD: Provide CAD/DXF of outsole outlines and any milling details; sample tooling typically starts within two weeks.

ORDERING CHECKLIST

Shoe category & target feel (sport/casual/sandal/safety)

Density/hardness window & thickness per size

Texture pattern(s) and traction goals (wet/dry)

Color(s) & branding (emboss/print/stripe)

Construction (single-layer, dual-density, EVA+cork, EVA+rubber cap)

Sheet size/lay plan and expected yield

Adhesive/lamination method upstream and downstream

Test/compliance requirements (abrasion, slip, REACH/CA65)

Packaging, labeling, and delivery timeline

Share the checklist and artwork to receive a tailored specification, sampling plan, and quotation.