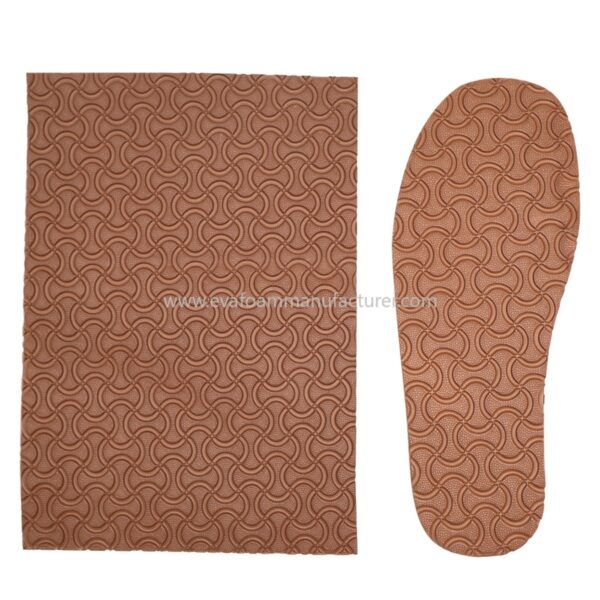

Introducing Our Textured Outsole Sheet

Exceptional Durability: Our textured outsole sheet is designed to withstand the rigors of daily use. Its robust construction ensures long-lasting performance, making it an ideal choice for all types of footwear, from casual sneakers to heavy-duty work boots.

Enhanced Comfort: The EVA material in our outsole sheet offers superior shock absorption, reducing the impact on joints and providing a comfortable walking experience. Your customers will appreciate the difference, enjoying unparalleled comfort with every step.

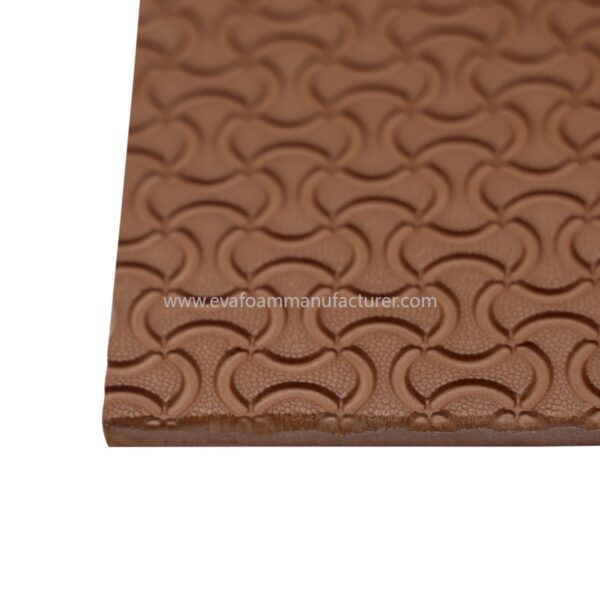

Superior Grip and Traction: The textured design of our outsole sheet significantly improves traction, reducing the risk of slips and falls. This feature is particularly beneficial for outdoor and athletic footwear, where secure footing is crucial.

Versatile Applications: Whether you’re designing sports shoes, casual footwear, or industrial boots, our textured outsole sheet is versatile enough to meet your needs. Its adaptability makes it a valuable addition to any footwear manufacturing process.

Aesthetic Appeal: In addition to its functional benefits, the textured outsole sheet adds a stylish touch to your shoe designs. Its unique texture not only enhances grip but also contributes to the overall aesthetic of the footwear, giving your products a modern and professional look.

Textured Outsole EVA Sheet for Sandal & Slipper Making — Data

Specifications

Material: EVA (closed-cell foam)

Applications: Shoes/outsoles/soles, packaging, bags, etc.

Grades: A+, A, B, C

Hardness: 30–80 Shore C

Colors: Multicolor; Pantone match available

Thickness: Customizable

Sample: Available

Origin: China

Overview

Durable, lightweight EVA outsole sheets with embossed textures for grip and style. The closed-cell structure delivers consistent cushioning, water resistance, and easy fabrication for high-throughput footwear lines.

Why choose our textured outsole sheets

Quality assurance: Tight QC for uniform hardness, density, and texture.

Customization: Thickness, color, texture, and cut sizes tailored to your spec.

Eco-minded: EVA formulation available with recyclable offcut handling.

Cost-effective: Competitive factory pricing without sacrificing performance.

Key benefits

Traction & wear resistance from embossed textures

Stable hardness range for different outsole zones

Excellent shock absorption and comfort

Water-resistant, easy to clean, and colorfast

Process-friendly: die-cutting, lamination, hot-press embossing, CNC trimming

Typical applications

Footwear: Sandal/slipper outsoles, midsoles, heel wedges, comfort inserts

Bags & luggage: Protective panels, handle padding

Packaging: Protective trays, edge guards for footwear shipments

Sports/leisure: Grip pads, lightweight protective pads

Processing options (on request)

PSA backing, fabric/rubber lamination, custom emboss patterns, logo deboss/laser mark, pre-cut kits

FAQ — Textured Outsole EVA Sheet

Q: What’s the lead time?

A: Standard rolls/sheets typically ship in ~25 days. Add 1–2 weeks for value-added steps like PSA, heat lamination, or looping.

Q: Can I get samples?

A: Yes. We provide sample sheets in various thicknesses, textures, and colors.

Q: Can you adjust softness/hardness or color?

A: Yes. We can tune hardness within 30–80 Shore C and match Pantone or your physical sample.

Q: Is EVA recyclable?

A: EVA can be recycled where facilities exist. We also recycle in-house offcuts to reduce waste.

Q: Can you build to my CAD file?

A: Yes. Share your CAD/prototype—after any minor DFM tweaks, we can begin sample production promptly.